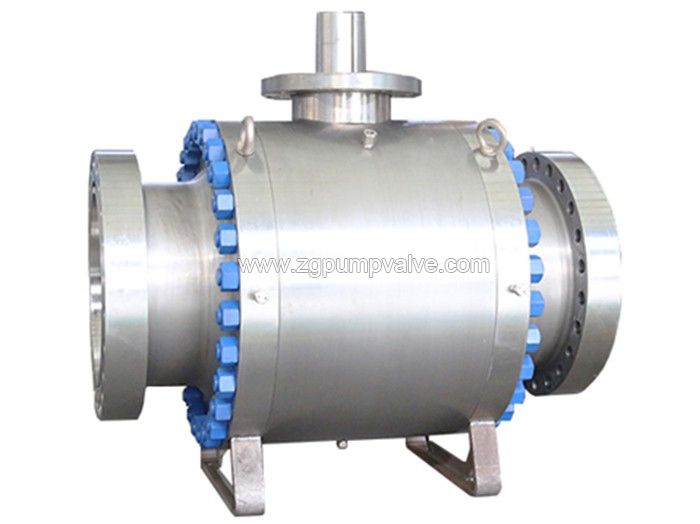

Ball valve

Forged steel floating ball valve

Product name: Forged steel split floating ball valve

DN: 1/2”(15)~ 8”(200)

CLASS(PN): 150LB(PN16)~2500LB(PN420)

Available materials: cast iron, stainless steel SS304, SS316, SS316L, 904L, duplex stainless steel CD4MCu, 2205, 2507, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

| Body structure: | Bolted body, forged steel |

| Valve seat: | Self-Relief / Double Piston Effect Seat / Upstream Self-Relief Valve Seat Downstream Double-Piston Effect Seat (Optional) |

| Ball: | Floating ball, solid |

| Flow pass: | Full bore / reduced diameter (optional) |

| Valve stem: | Anti-blowout, can be lengthened (optional) |

| Operation mode: | Manual / electric / pneumatic / pneumatic-hydraulic linkage / electro-hydraulic linkage / hydraulic (optional) |

| Seal: | Soft seal / metal seal / composite seal (primary metal seal + secondary soft seal) |

| Grease injection valve: | Not applicable |

| Vent valve: | Not applicable |

| Sewage valve: | Not applicable |

| Locking device: | Optional |

| Leak rating: | Soft seal: ISO 5208 Class A, metal seal: ISO 5208 Class C or higher, ANSI VI |

| Material of main parts | |

| Valve body | Carbon steel / stainless steel / alloy steel forgings |

| Ball | Carbon steel / stainless steel / alloy steel forging nickel / chrome / spray welding hard alloy |

| Support ring | Carbon steel / stainless steel / alloy steel forging nickel / chrome / spray welding hard alloy |

| Valve seat | PTFE, RPTFE, VITON, NYLON, DEVLON, MOLON, PEEK/Seal face spray welding, tungsten carbide |

| Valve stem | Stainless steel / alloy steel / INCONEL, etc. |

| Packing | PTFE, graphite, etc. |

| Bolts and nuts | A193/A194, A320, etc. |

| Pressure temperature class: | ASME B16.34 GB/T12224 |

| Design: | BS 5351, API 608, ASME B16.34, API 6D, GB, GOST, DIN, BS,etc. |

| Test: | API 6D / API 598 / GB/T 13927 and other relevantNational standards. |

| Structure length: | API 6D, ANSI B16.10, GB 12221, GOST, DIN, BS/ manufacture standard / user requirements. |

| Connection end: | BW (ASME B16.25, ASME B31.8 / GB / T12224 and other national standards), RF (ASME B16.5, ASME B16.47, GB / JB / HG / GOST, DIN, etc.), RTJ (ASME B16. 5, ASME B16.47, GB / JB / HG / GOST, DIN, etc.), BW + PUP (the length of the transition tube is customized) |

| Fire protection requirements: | API 607/API 6FA/BS 6755 |

| Anti-static electricity: | API 608/BS 5351 |

| Valve anti-sulfur: | NACE MR. 0175 |

The valve body uses forgings to prevent casting defects, split bolt connections, and easy maintenance.

Company video

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

+86 28 8218 1182

-

+86 28 8218 1182