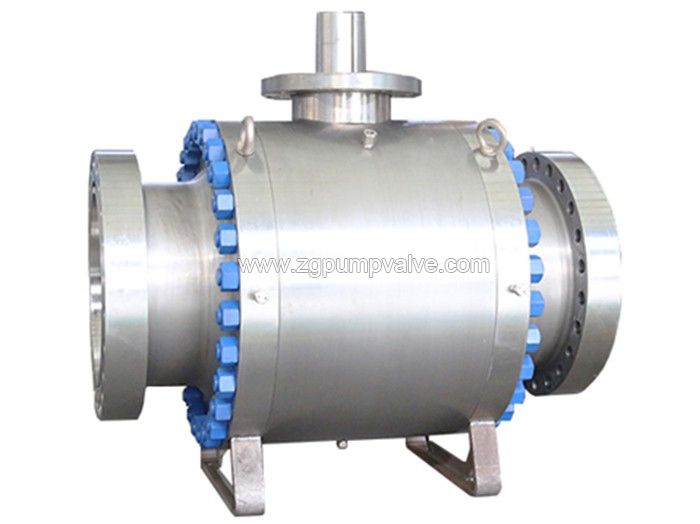

Ball valve

Forged Steel Full Welded Ball Valve

Product name: Forged steel fully welded ball valve

DN: 2”(50)~ 56”(1400)

CLASS(PN): 150LB(PN16)~2500LB(PN420)

Available materials: cast iron, stainless steel SS304, SS316, SS316L, 904L, duplex stainless steel CD4MCu, 2205, 2507, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

None

| Body structure: | Fully welded, forged steel |

| Valve seat: | Self-Relief / Double Piston Effect Seat / Upstream Self-Relief Valve Seat Downstream Double-Piston Effect Seat (Optional) |

| Ball: | Trunnion mounted ,solid |

| Flow pass: | Full bore / reduced diameter (optional) |

| Valve stem: | Anti-blowout, can be lengthened (optional) |

| Support: | The upper and lower support structure, the valve stem is not subject to radial bending moment, only bears the torque, and the switching torque is light. |

| Operation mode: | Manual / electric / pneumatic / pneumatic-hydraulic linkage / electro-hydraulic linkage / hydraulic (optional) |

| Seal: | Soft seal / metal seal / composite seal (primary metal seal + secondary soft seal) |

| Grease injection valve: | Optional |

| Vent valve: | Optional |

| Sewage valve: | Optional |

| Locking device: | Optional |

| Leak rating: | Soft seal: ISO 5208 Class A, metal seal: ISO 5208 Class C or higher, ANSI VI |

None

| Material of main parts | |

| Valve body | Carbon steel / stainless steel / alloy steel forgings |

| Ball | Carbon steel / stainless steel / alloy steel forging nickel / chrome / spray welding hard alloy |

| Support ring | Carbon steel / stainless steel / alloy steel forging nickel / chrome / spray welding hard alloy |

| Valve seat | PTFE, RPTFE, VITON, NYLON, DEVLON, MOLON, PEEK/Seal face spray welding, tungsten carbide |

| Valve stem | Stainless steel / alloy steel / INCONEL, etc. |

| O ring | VITON/NR/HNBR/NBR/FKM/EPDM, etc. |

| Bolts and nuts | A193/A194, A320/GB/HG, etc. |

None

| Pressure temperature class: | ASME B16.34 GB/T12224 |

| Design: | ASME B16.34, API 6D, GB, GOST, DIN, BS,etc. |

| Test: | API 6D / API 598 / GB/T 13927 and other relevantNational standards. |

| Structure length: | API 6D, ANSI B16.10, GB 12221, GOST, DIN, BS/ manufacture standard / user requirements. |

| Connection end: | BW (ASME B16.25, ASME B31.8 / GB / T12224 and other national standards), RF (ASME B16.5, ASME B16.47, GB / JB / HG / GOST, DIN, etc.), RTJ (ASME B16. 5, ASME B16.47, GB / JB / HG / GOST, DIN, etc.), BW + PUP (the length of the transition tube is customized) |

| Fire protection requirements: | API 607/API 6FA/BS 6755 |

| Anti-static electricity: | API 608/BS 5351 |

| Valve anti-sulfur: | NACE MR. 0175 |

The valve body adopts forged steel and fully welded structure, which eliminates the casting defects of the casting and prevents any possible leakage. It is especially suitable for the working conditions of long-distance oil and gas pipelines.

Company video

-

+86 28 8218 1182

-

+86 28 8218 1182