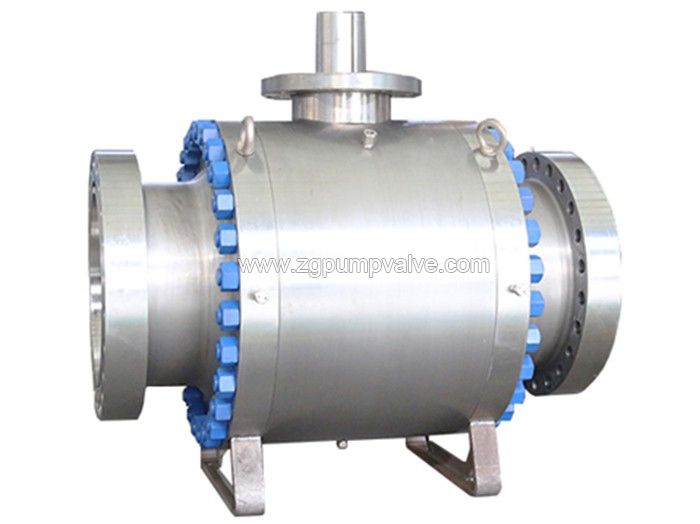

Ball valve

PE ended ball valve

Product name: PE ended ball valve

DN: 1/4”(32)~ 16”(400)

CLASS(PN): 1.0MPa

Available materials: cast iron, stainless steel SS304, SS316, SS316L, 904L, duplex stainless steel CD4MCu, 2205, 2507, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

| Body structure: | Fully welded, the valve body is mainly welded from forged steel (small diameter steel pipe). |

| Valve seat: | Self-Relief / Double Piston Effect Seat / Upstream Self-Relief Valve Seat Downstream Double-Piston Effect Seat (Optional) |

| Ball: | Trunnion mounted / floating,solid |

| Flow pass: | Full bore / reduced diameter (optional) |

| Valve stem: | Anti-blowout, can be lengthened (optional) |

| Operation mode: | Manual / electric / pneumatic / pneumatic-hydraulic linkage / electro-hydraulic linkage / hydraulic (optional) |

| Seal: | Soft seal / composite seal (primary metal seal + secondary soft seal) |

| Grease injection valve: | Optional |

| Vent valve: | Optional |

| Sewage valve: | Optional |

| Locking device: | Optional |

| Bleeding valve: | No bleeding valve / single bleeding valve / double bleeding valve (optional). |

| Leak rating: | Soft seal: ISO 5208 Class A, metal seal: ISO 5208 Class C or higher, ANSI VI |

| Material of main parts | |

| Valve body | Carbon steel / stainless steel / alloy steel (pipe) |

| Ball | Carbon steel / stainless steel / alloy steel forging nickel / chrome plating |

| Support ring | Carbon steel / stainless steel / alloy steel forging nickel / chrome plating |

| Valve seat | PTFE, RPTFE, VITON, NYLON, , MOLON |

| Valve stem | Stainless steel / alloy steel / INCONEL, etc. |

| O ring | VITON/NR/HNBR/NBR/FKM/EPDM, etc. |

| Bolts and nuts | A193/A194, A320, etc. |

| Pressure temperature class: | ASME B16.34 |

| Design: | BS 5351, API 608, ASME B16.34, API 6D, GB, GOST, DIN, BS |

| Test: | API 6D / API 598 / GB/T 13927 and other relevantNational standards. |

| Structure length: | API 6D, ANSI B16.10, GB 12221, GOST, DIN, BS/ manufacture standard / user requirements. |

| Connection end: | PE pipe |

| Fire protection requirements: | API 607/API 6FA/BS 6755 |

| Anti-static electricity: | API 608/BS 5351 |

| Valve anti-sulfur: | NACE MR. 0175 |

The valve body adopts a forged steel all-welded ball valve structure, and the pipe is connected with a PE (polyethylene plastic) pipe. This steel-plastic composite design avoids the disadvantages of switch failure and damage caused by the aging of the valve body and the operating part material in the long-term use of pure PE ball valves, so it is not easy to cause leakage caused by aging and damage to PE, and the service life is long, and Safe and reliable, easy installation on site.

Company video

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

+86 28 8218 1182

-

+86 28 8218 1182