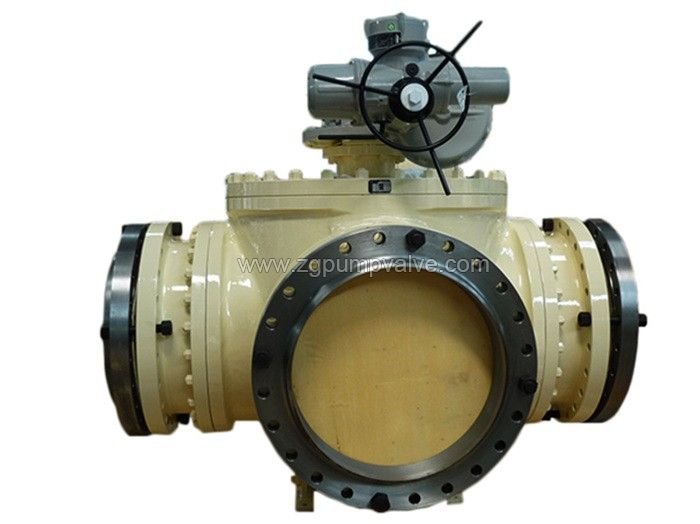

Ball valve

Three-way / four-way ball valve

Product name: Three-way / four-way ball valve

DN: 1/2”(15)~ 24”(600)

CLASS(PN): 150LB(PN16)~2500LB(PN420)

Available materials: cast iron, stainless steel SS304, SS316, SS316L, 904L, duplex stainless steel CD4MCu, 2205, 2507, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

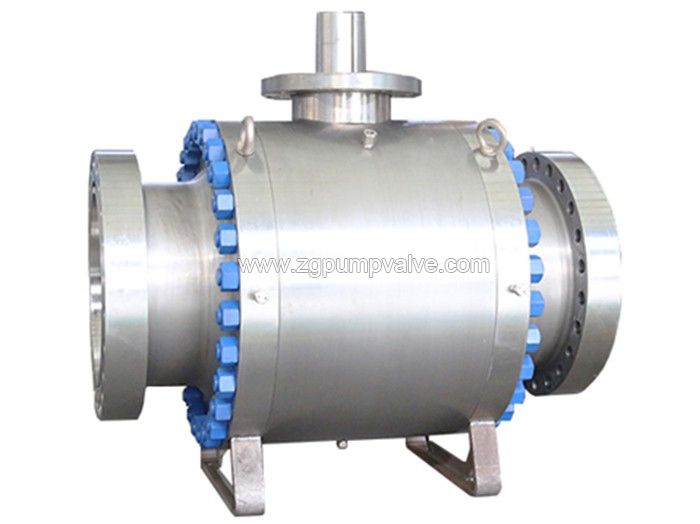

| Body structure: | Forged steel body / cast steel body, bolted body |

| Valve seat: | Self-Relief / Double Piston Effect Seat / Upstream Self-Relief Valve Seat Downstream Double-Piston Effect Seat (Optional) |

| Ball: | Floating ball/trunnion ball,top entry/side entry,solid |

| Flow pass: | Full bore / reduced diameter (optional) |

| Valve stem: | Anti-blowout, can be lengthened (optional) |

| Function: | L type / T type three / four way, X type 4 way |

| Operation mode: | Manual / electric / pneumatic / pneumatic-hydraulic linkage / electro-hydraulic linkage / hydraulic (optional) |

| Seal: | Soft seal / metal seal / composite seal |

| Grease injection valve: | Optional |

| Vent valve: | Optional |

| Sewage valve: | Optional |

| Locking device: | Optional |

| Leak rating: | Soft seal: ISO 5208 Class A, metal seal: ISO 5208 Class C or higher, ANSI VI |

| Material of main parts | |

| Valve body | Carbon steel / stainless steel / alloy steel forgings |

| Ball | Carbon steel / stainless steel / alloy steel forging nickel / chrome / spray welding hard alloy |

| Support ring | Carbon steel / stainless steel / alloy steel forging nickel / chrome / spray welding hard alloy |

| Valve seat | PTFE, RPTFE, VITON, NYLON, DEVLON, MOLON, PEEK/Seal face spray welding, tungsten carbide |

| Valve stem | Stainless steel / alloy steel / INCONEL, etc. |

| Seals | VITON, PTFE, GRAPHITE, etc. |

| Bolts and nuts | A193/A194, A320/GB/HG, etc. |

| Pressure temperature class: | ASME B16.34 |

| Design: | ASME B16.34, API 6D, GB, GOST, DIN, BS,etc. |

| Test: | API 6D / API 598 / GB / T 13927 and other relevant national standards. |

| Structure length: | API 6D, ANSI B16.10, GB 12221, GOST, DIN, BS/ manufacture standard / user requirements. |

| Connection end: | BW (ASME B16.25, ASME B31.8 / GB / T12224 and other national standards), RF (ASME B16.5, ASME B16.47, GB / JB / HG / GOST, DIN, etc.), RTJ (ASME B16. 5, ASME B16.47, GB / JB / HG / GOST, DIN, etc.), BW + PUP (the length of the transition tube is customized) |

| Fire protection requirements: | API 607/API 6FA/BS 6755 |

| Anti-static electricity: | API 608/BS 5351 |

| Valve anti-sulfur: | NACE MR. 0175 |

It is used to switch the flow direction or split or partial split.

The four-way ball valve is called a two-way water supply rotary valve (also known as an air reversing switching valve in a petrochemical system) in a power station system, and is suitable for the circulation system of liquid, gas, dust, slurry and solid particles. For example: the forward and reverse circulation water supply system of the power plant unit cooler. The traditional process piping method realizes the cooling forward and reverse circulation water supply. The device occupies a large space, high cost, and tedious operation (four valves need to be operated each time). When the water supply is wanted, valves 1 and 3 are opened and valves 2 and 4 are closed. During reverse water supply, valves 2 and 4 are opened, and valves 1 and 3 are closed. A four-way ball valve is used to replace the working principle of the manifold and valve group, which simplifies procedures, facilitates operation, reduces costs, facilitates control, and has good synchronization.

Company video

-

+86 28 8218 1182

-

+86 28 8218 1182