Chemical Pump

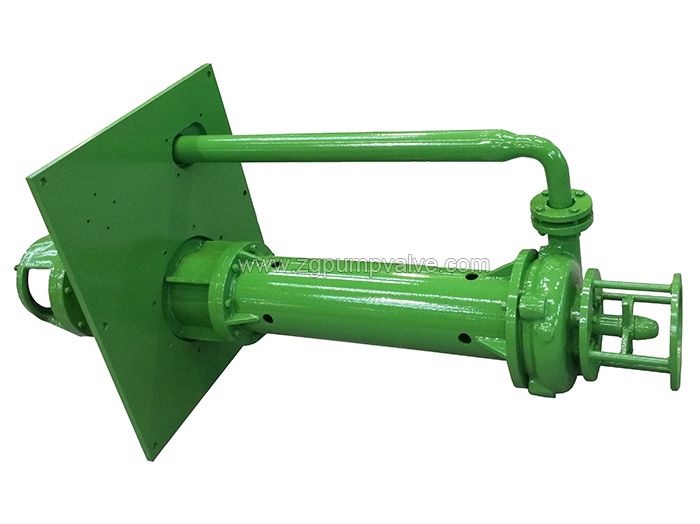

Vertical submerged chemical pump

ZLF vertical submerged chemical pump(also known as semi-submersible chemical pumps and vertical long shaft pumps) adopts double bearing supporting to improve the reliability and stability of operation. A suction pump below 2 m length can be added to pump inlet according to the requirement of working liquid level. Various materials are available for different applications. ZLF vertical submerged chemical pump is suitable for conveying fluids without solids or fluids with a few suspending particles. It is widely used in industries of electric power, mining, cement, metallurgy, non-ferrous metals...There are various materials available for our vertical submerged chemical pump, including stainless steel cast iron,SS304, SS316, SS316L, 904L, duplex stainless steel CD4MCu, 2205, 2507, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

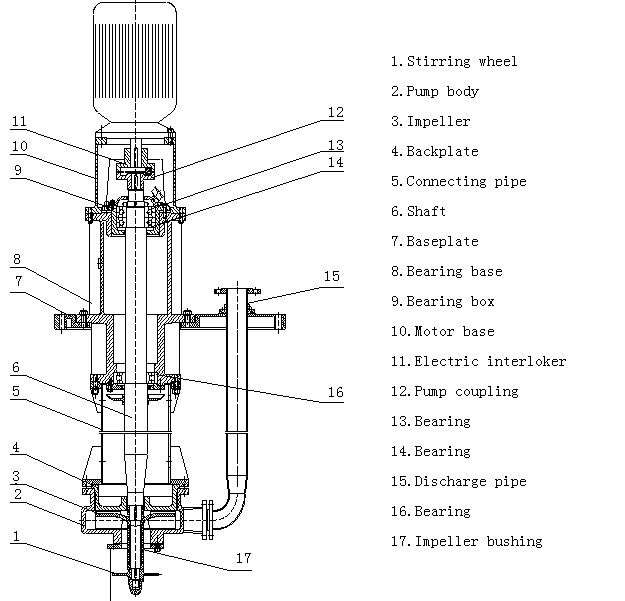

Structure

-

MOC

-

Configuration

-

Application

-

Performance

■Flow rate: Q=9~460 (m³/h)

■Total head: H=10~65 (m)

■Pump speed: n=1450rpm

■Fluid s.g.: γ ≤1.5

■Fluid temperature: T=0~80℃

■Pump diameter: 50~200mm

■A new type vertical submerged centrifugal chemical pump conforms to standard JB/T8096-1998.

■Double bearing supporting to improve the reliability and stability of operation.

■Optimized hydraulic model to better adapt different applications.

■Several standard immersed depths of pump. A suction pipe can be added onto pump inlet flange when the pump immersed depth is longer than 1.5 m.

■Adopting low linear speed design for heavy slurry to extend pump life.

■Different anti-abrasive materials for various applications.

■Single casing structure, pump casing is connected to the supporting tube, supporting tube is connected to bearing housing, bearing housing is connected to baseplate.

■Cylinder type bearing housing plus rolling bearings.

■Sealing ring as the shaft sealing, without any cooling water.

■A stir impeller is adopted beyond the impeller of ZLJ model to agitate slurry or particles in the fluids.

■Direct coupled Transmission.

The structure is as follows:

1.Stirring wheel 2.Pump casing 3.Impeller 4.Back plate 5.Connecting pipe 6.Shaft | 7.Base plate 8.Bearing base 9.Bearing box 10.Motor base 11.Electric interloker 12.Pump coupling | 13.Bearing 14.Bearing 15.Discharge pipe 16.Bearing 17.Impeller bushing |

■Various materials as 1C18Ni9、0C18Ni12Mn2Ti、0Cr18Ni9、316、316L、Cr30... Other materials are available for special applications.

■CI for bearing housing and baseplate.

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

| Couplings |  | Pin type | Flexible diaphragm coupling |

■Sewage water conveying for industries of electric power, mining, cement, metallurgy and non-ferrous metals.

■Fluid conveying for aluminum oxide process.

■Other slurry conveying of settling pond.

Company video

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

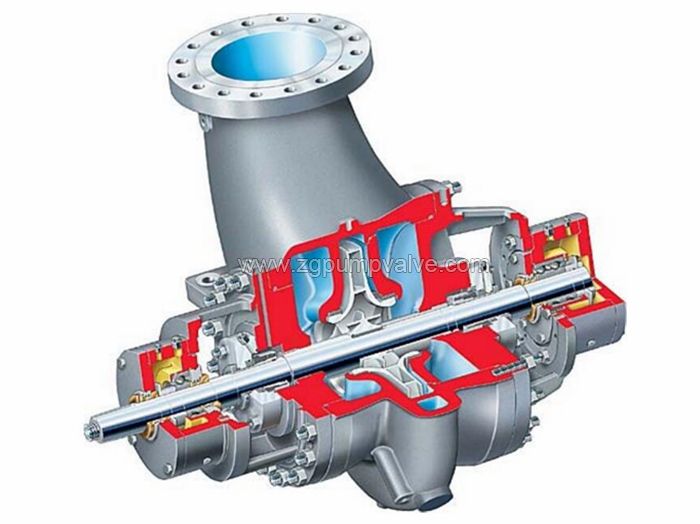

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

+86 28 8218 1182

-

+86 28 8218 1182