Chemical Pump

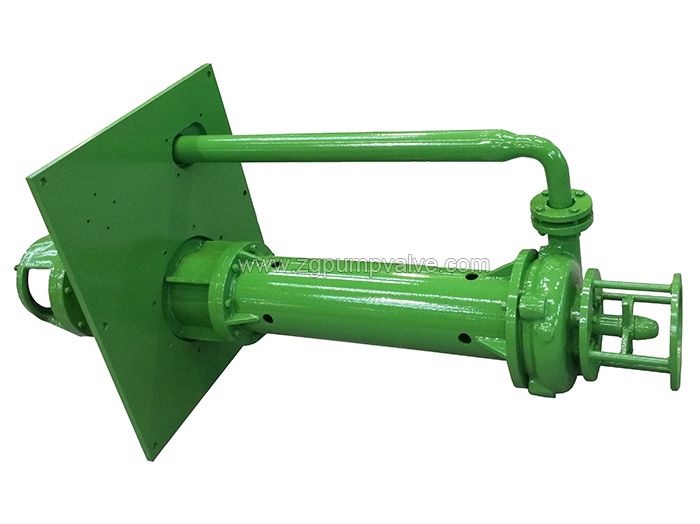

Chemical mixed flow pump

The hydraulic model of ZHH chemical mixed flow pump is optimized by CFD, with the advantages of stable, high efficiency, energy-saving and low operating cost. The ZHH series has full specifications, its pump diameter is from 200 mm to 900 mm, and therefore is able to satisfy the different capacity of various process. It is suitable for the fluid circulation of ammonium phosphate and potash fertilizer process, and it is the most ideal pump for such processes. ZHH mixed flow pump can be also used in the similar chemical applications to form the forced circulation of big flow of corrosive fluids with suspending particles.There are various materials available for our mixed flow pump, including stainless steel SS304, SS316, SS316L, 904L, duplex stainless steel CD4MCu, 2205, 2507, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

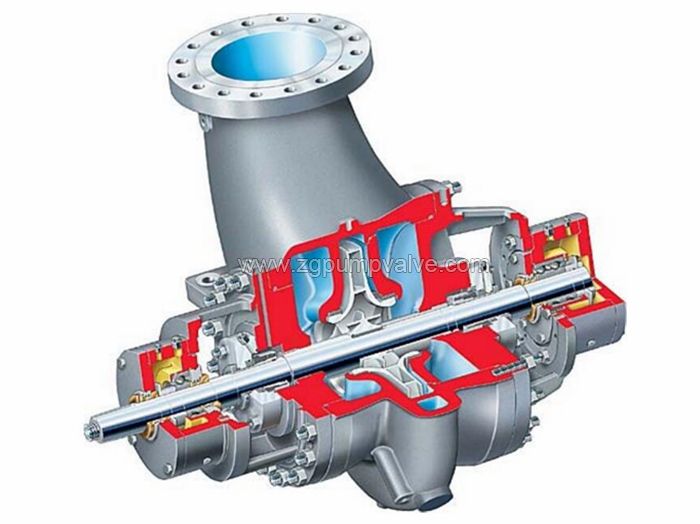

Structure

-

MOC

-

Configuration

-

Application

-

Performance

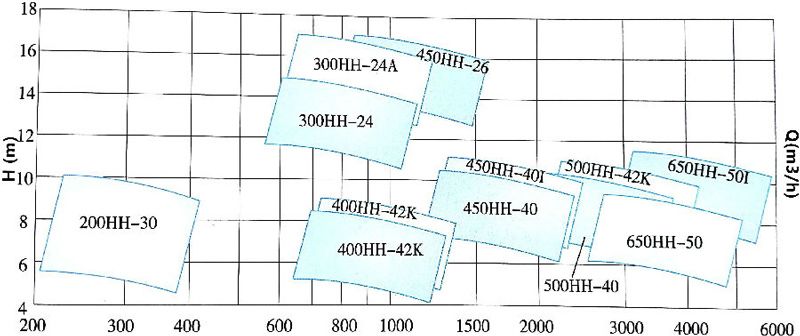

■Flow rate: Q= 200~8300(m³/h)

■Total head: H= 5~19 (m)

■Pump speed: n=490~1450rpm

■Fluid s.g.: γ ≤1.5

■Fluid temperature: T=0~105℃

■Pump diameter: 200~900mm

■The hydraulic model is optimized by CFD, with excellent anti-cavitation performance.

■Elaborate design and manufacturing based on the fluid requirements of ammonium phosphate and potash fertilizer process, is able to satisfy various capacity requirements.

■The rotor part can be adjusted by the bearing housing, which enables the convenient method to recover the pump performance after slight abrasion of pump.

■Axial direction adjustable rotor part. The gap between the impeller and the front cover can be adjusted to enable stable operation at high efficiency.

■Pump diameter from 200 mm to 900 mm. A lot of real sales achievements for each specification.

■The discharge direction can be customized based on the requirements of process.

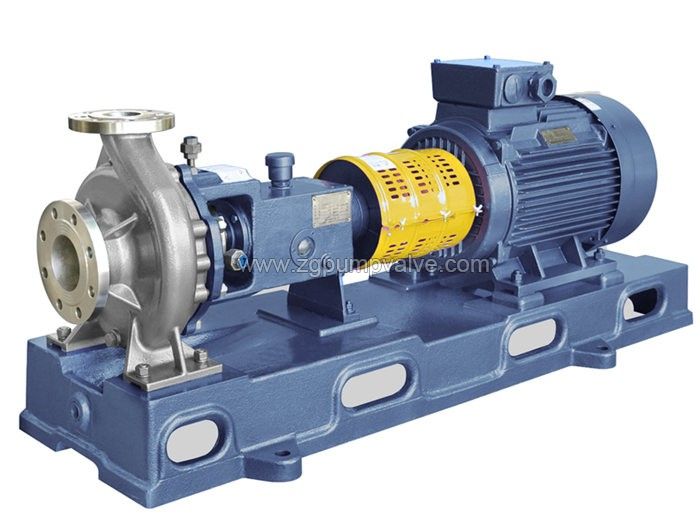

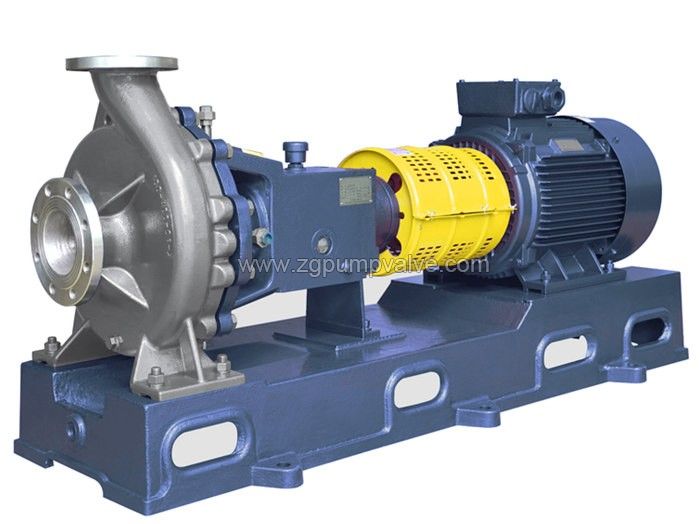

■Horizontal,single stage,single suction,cantilever type,volute casing,direct coupled transmission.

■Back pull design. During maintenance,the rotor part plus the pump rear cover can be pulled out from the casing without dismantle the inlet and outlet pipes.

■Pump shaft sealing consists of dynamic seal and packing.

■Bearing housing is back pull structure,and connected to pump casing by pump rear cover.

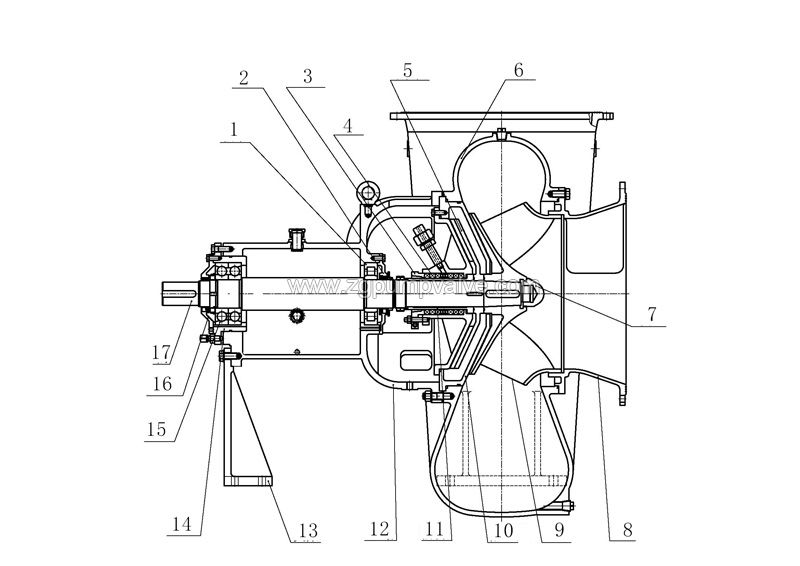

Structure drawing is as below:

1. Bearing 2. Bearing gland 3. Packing gland 4. Packing 5. Vice impeller 6. Pump casing | 7. Impeller nut 8. Front pump cover 9. Impeller 10. Rear pump gland 11. Shaft sleeve 12. Bearing housing | 13. Base plate 14. Bearing box 15. Bearing 16. Bearing gland 17. Shaft |

| No. | Description | Material | |||||

| Anti-corrosion alloy | Cast steel | Stainless steel | |||||

China standard | ASTM standard | China standard | ASTM standard | China standard | ASTM standard | ||

| 1 | Pump casing | 20# Alloy Titanium Nickel 904L Ti/Pd Alloy Monel | Hastelloy Monel Ⅱ-B Ⅱ-C Ni-Resist1 Ni-Resist2 Ni-Resist3 | 25# 35# | WCA WCB | ZG1Cr13 ZG2Cr13 ZG00Cr18Ni10 ZG0Cr18Ni9 ZG0Cr18Ni12Mo2Ti ZG0Cr17Ni4CuNb ZG1Cr18Ni9 ZG1Cr18Ni9Ti ZG00Cr17Ni14Mo2 0Cr26Ni5Mo2 0Cr17Mn13Mo2N 00Cr18Ni5Mo3Si2 | CA-15 CA-15M CF-3(SS304L) CF-8(SS304) CF-8M(SS316) CF-3M(SS316L) CN-7M(SS320) CD-4MCu 2205 |

| 2 | Sealing ring | ||||||

| 3 | Impeller | ||||||

| 4 | Pump cover | ||||||

| 5 | Impeller nut | ||||||

| 6 | Cartridge seal | ||||||

| 7 | Shaft | Carbon steel SS420 2205 SS304 SS316 | |||||

| 8 | Bearing Housing | Cast iron | |||||

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Mechanical seal |  | Zigong brand | Burgmann, Sihuan Riji, Chengdu Yitong |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

| Couplings |  | Pin type | Flexible diaphragm coupling |

■Fluid circulation of ammonium phosphate and potash fertilizer process.

■Forced circulation of big flow of corrosive fluids with suspending particles.

Company video

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

+86 28 8218 1182

-

+86 28 8218 1182