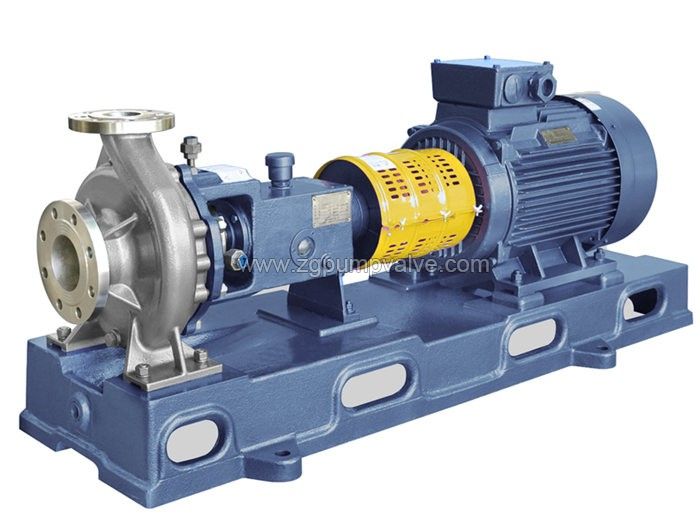

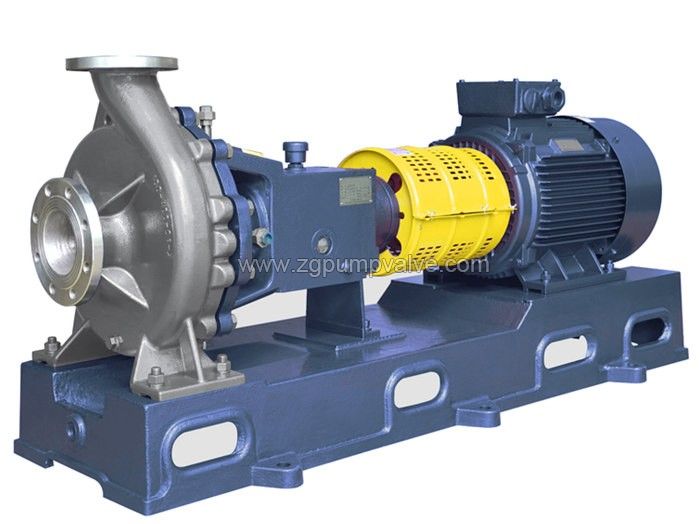

Chemical Pump

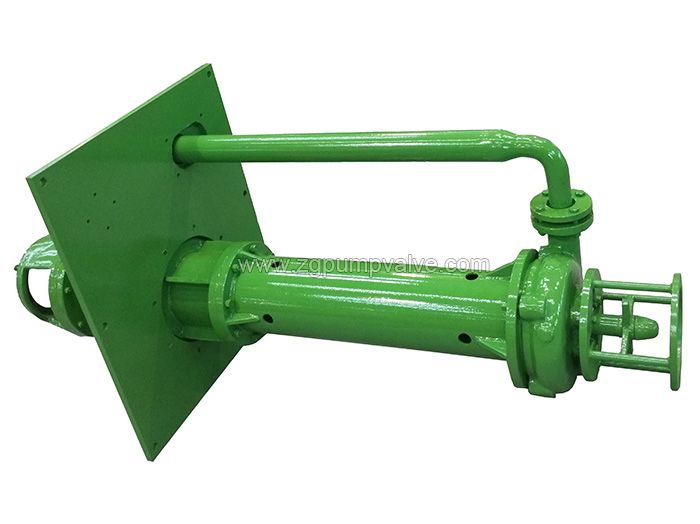

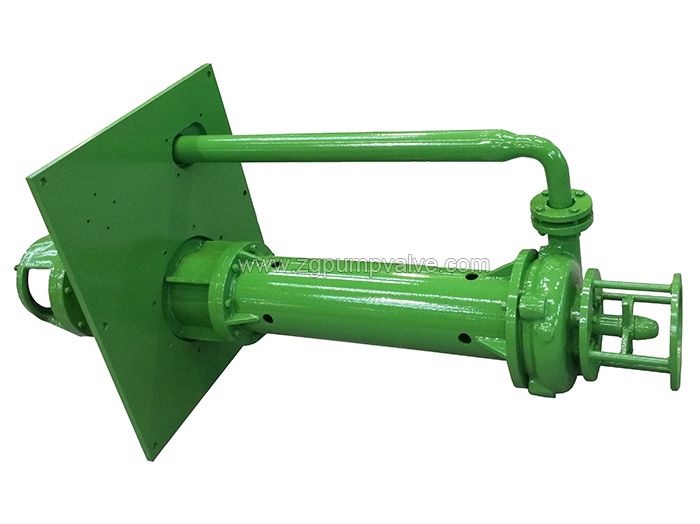

Chemical submerged slurry pump

HY series chemical submerged pump(also known as semi-submersible pump) is a vertical centrifugal pump of single stage,end suction, with innovation design, energy-saving and green products.It absorbs the advanced technology of HZ series chemical pump according to the market demand. It is applied to the Petrochemical, chemical, metallurgical, depot, sewage treatment industries, etc; conveying toxic and corrosive liquid which is clean or contains only very little suspended particles and crystallized substances.There are various materials available for our chemical submerged slurry pump, including cast iron,stainless steel SS304, SS316, SS316L, 904L, duplex stainless steel CD4MCu, 2205, 2507, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

■Flow rate:Q=0.3~2400m3/h

■Total head:H=5~230m

■Nozzles(DN): (25~500)mm

■Pressure: 2.5 Mpa

■Temperature:T=--40~400℃

■Immersion in liquid, pump self-suction capacity, operation without filling water, start or stop at any time, convenient use; No seal, no leakage, safety and environmental protection;A high degree of generalization, modular design for main parts such as base plate, supporting tube, shaft housing, great reducing storage of the pare parts, prevention of sundry due to filter.

■HYK series pump is a vertical centrifugal pump of single stage, end suction with open impeller, which is a successful submerged slurry pump based on long-time technology accumulation and on the experience of domestic and overseas advanced technology. With smooth operation, it has strong capacity to convey fibre and particles. Also, it is suitable for conveying the paper-making, metallurgical, fertilizers, salt collecting, drainage industries, etc;usually with the pulp below 8% density and other liquid with the solid content below 30%.

■The HYS series is the improved product of HYK submerged pump. It has the same structure and performance with HYK series pump. The wetted parts can be used the special material, suitable for the high temperature, high concentration liquid, such as concentrated sulfuric acid and in other acid environments.

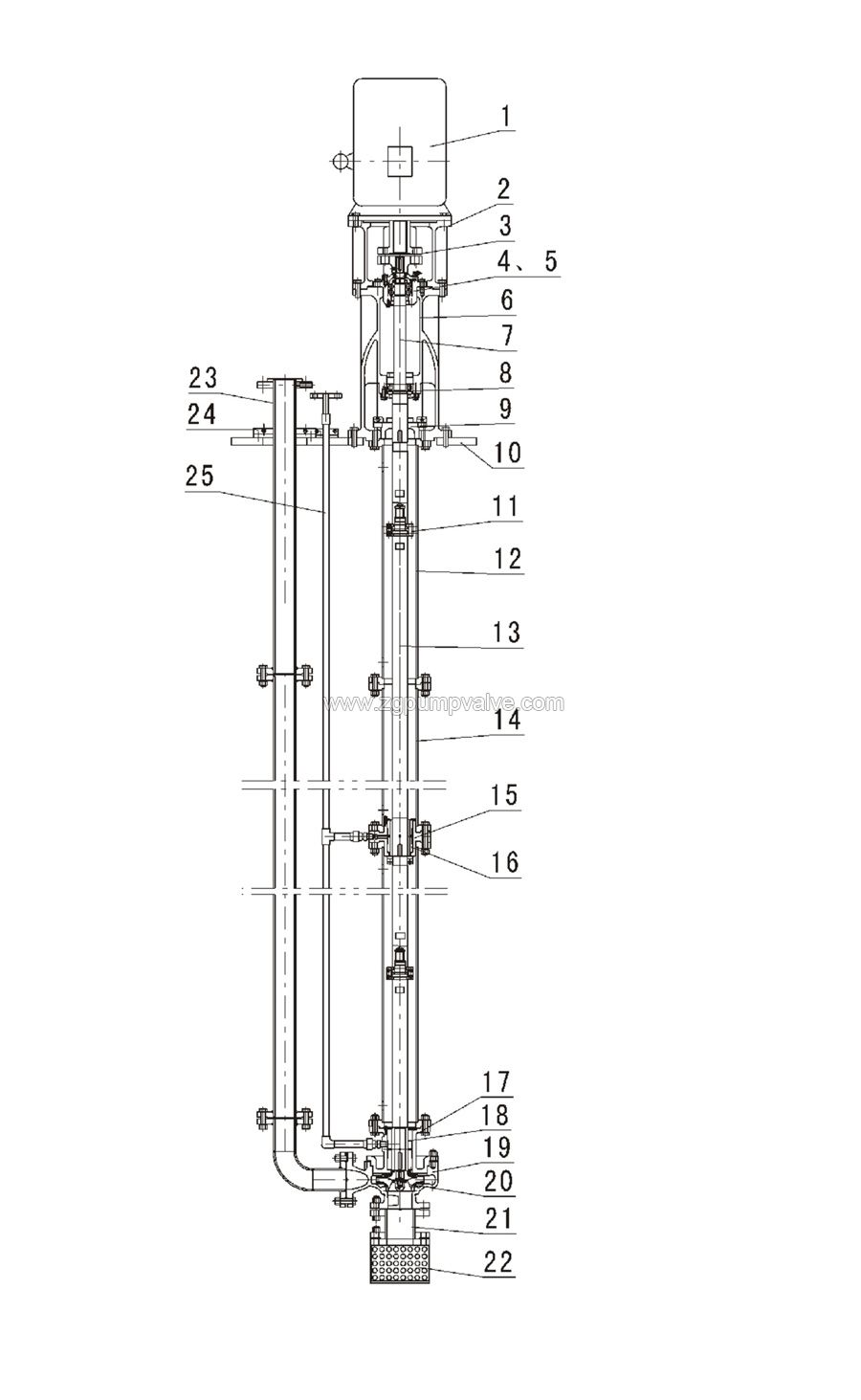

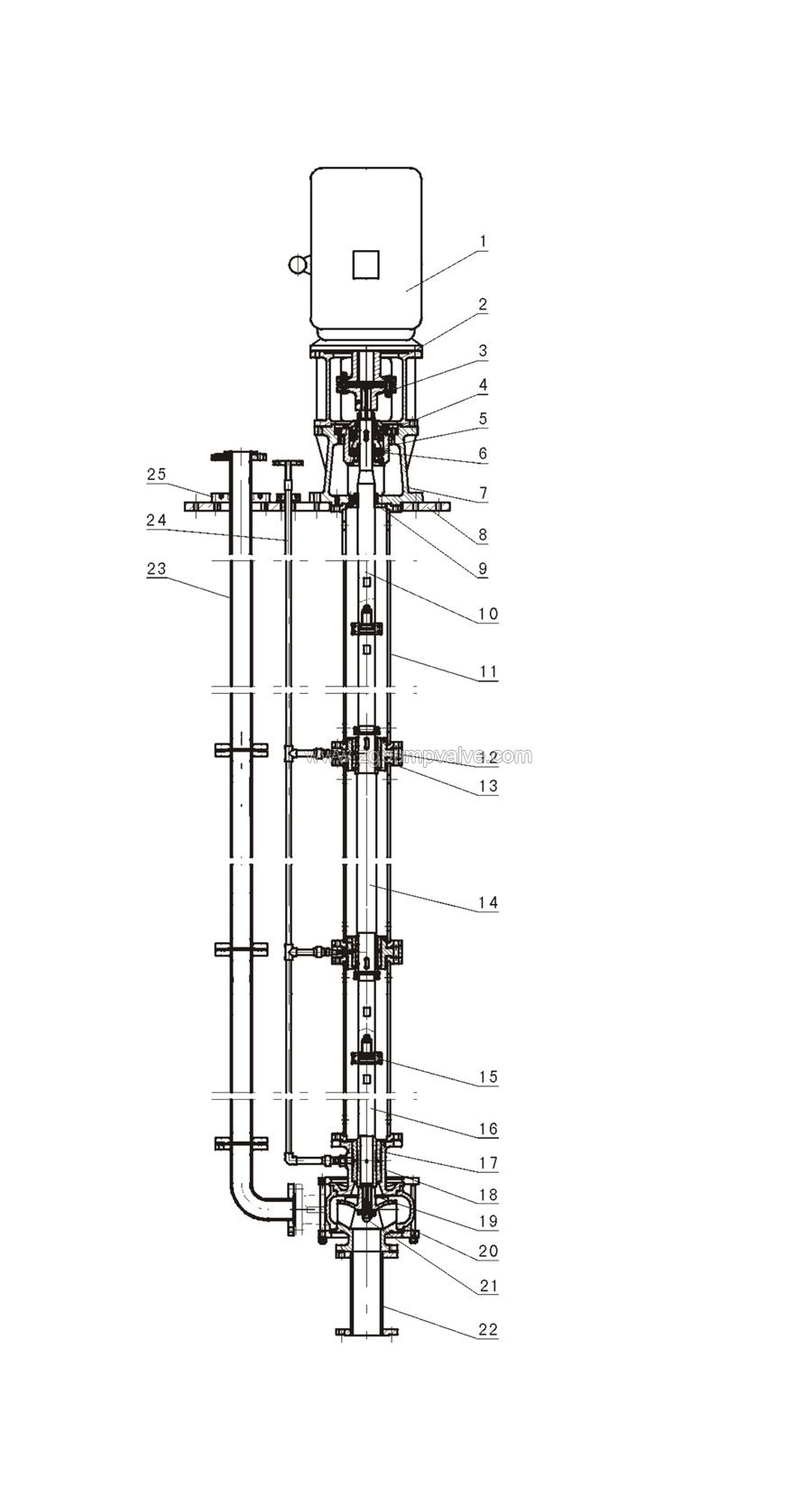

HY, HYK/HYS structure illustration

■Supporting way

HY, HYK/HYS series pump adopt two structure mode: Figure 1: Multi-spot supporting mode. This structure is adopted if the submerged level is deep and the fluid is clean. Figure 2: Cantilever support mode. This structure is applied if the submerged level is not deep and the fluid containing solid, especially when the fluid is crystallizing.

■Impeller/filter style

HY series pump is using the closed impeller, in order to prevent the bigger particles entering into the passage and being jammed. The filter cover is installed in the inlet of the pump to filter the liquid passing into the pump chamber, ensuring the normal use of the pump.

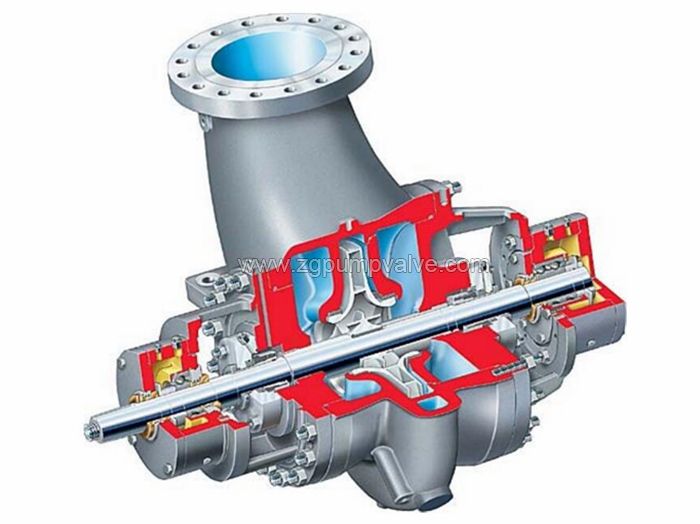

HY standard type pump's structural diagram

| 1.Motor 2.Intermediate support 3.Coupling 4.Bearing sleeve 5.Bearing 6.Bearing block 7.Shaft 8.Bearing 9.Sealing component | 10.Base plate 11.Shaft hooping 12.Supporting tube 13.Intermediate shaft 14.Supporting tube 15.Packing sleeve 16.Integral packing 17.Pump cover 18.Integral packing | 19.Pump casing 20.Impeller 21.Liquid refilling pipe 22.Filter mantle 23.Drain pipe 24.Hooping 25.Flushing pipe |

The long shaft type pump's structural diagram with the submerged depth which exceeds 3.5m

| 1.Motor 2.Intermediate support 3.Coupling 4.Bearing 5.Bearing sleeve 6.Bearing 7.Bearing block 8.Base plate 9.Sealing component | 10.Shaft11.Supporting tube 12.Packing sleeve 13.Integral packing 14.Intermediate shaft 15.Shaft hooping 16.Shaft 17.Integral packing 18.Pump cover | 19.Impeller 20.Pump casing 21.Impeller nut 22.Liquid refilling pipe 23.Drain pipe 24.Flushing pipe 25.Hooping |

| No. | Description | Material | |||||

| Anti-corrosion alloy | Cast steel | Stainless steel | |||||

China standard | ASTM standard | China standard | ASTM standard | China standard | ASTM standard | ||

| 1 | Pump casing | 20# Alloy Titanium Nickel 904L Ti/Pd Alloy Monel | Hastelloy Monel Ⅱ-B Ⅱ-C Ni-Resist1 Ni-Resist2 Ni-Resist3 | 25# 35# | WCA WCB | ZG1Cr13 ZG2Cr13 ZG00Cr18Ni10 ZG0Cr18Ni9 ZG0Cr18Ni12Mo2Ti ZG0Cr17Ni4CuNb ZG1Cr18Ni9 ZG1Cr18Ni9Ti ZG00Cr17Ni14Mo2 0Cr26Ni5Mo2 0Cr17Mn13Mo2N 00Cr18Ni5Mo3Si2 | CA-15 CA-15M CF-3(SS304L) CF-8(SS304) CF-8M(SS316) CF-3M(SS316L) CN-7M(SS320) CD-4MCu 2205 |

| 2 | Sealing ring | ||||||

| 3 | Impeller | ||||||

| 4 | Pump cover | ||||||

| 5 | Impeller nut | ||||||

| 6 | Cartridge seal | ||||||

| 7 | Shaft | Carbon steel SS420 2205 SS304 SS316 | |||||

| 8 | Bearing Housing | Cast iron | |||||

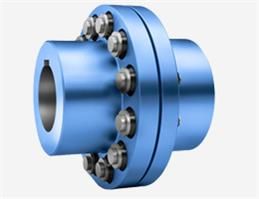

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

| Couplings |  | Pin type | Flexible diaphragm coupling |

■HY chemical submerged pump can be used to convey clean liquid or corrosive liquid containing small quantities of solid particles and crystalline mass.

■HYK─open type impeller, conveying pulp with the concentration less than 8% and gypsum pulp with solid content less than 3%.

■HYM─the wear-resistance material, suitable for conveying bentonite, abrasive tool, limemilk, lime stone gypsum, and sand-containing crude oil etc.

■HYS─application to high temperature, high concentration under the acid conditions, such as the sulfuric acid.

Company video

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

+86 28 8218 1182

-

+86 28 8218 1182