Chemical Pump

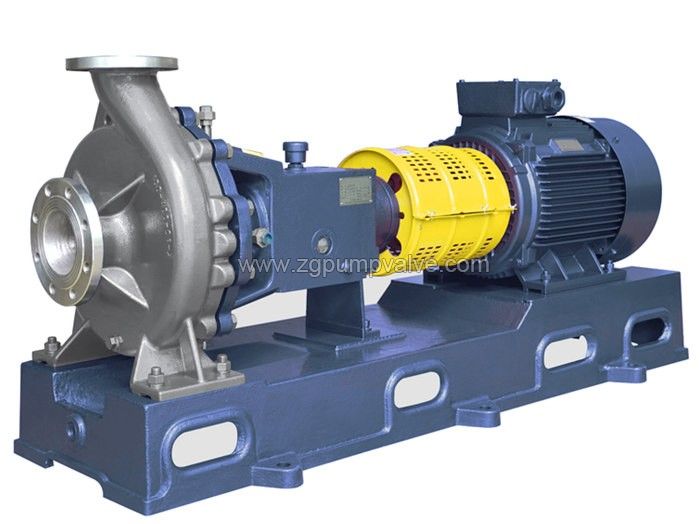

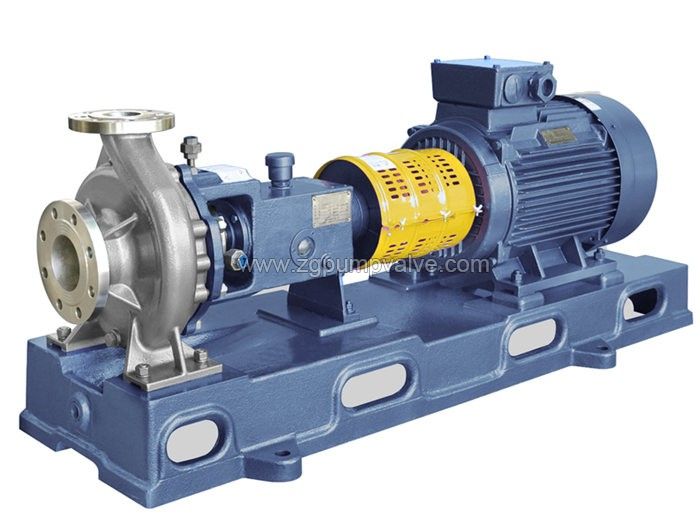

Electric motor chemical pump

ZXF electric motor driven pump is a centrifugal pump of single stage, single suction and cantilever type. It is mainly applicable for processes of petrochemical, chemical, synthetic fiber, fertilizer, power plant, metallurgy, food and medicine... And it is suitable to pump clean fluids, fluids of low temperature or high temperature, and corrosive fluids. Its design temperature range is -20℃~150℃.There are various materials available for our electric motor driven pump, including stainless steel SS304, SS316, SS316L, 904L, duplex stainless steel CD4MCu, 2205, 2507, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

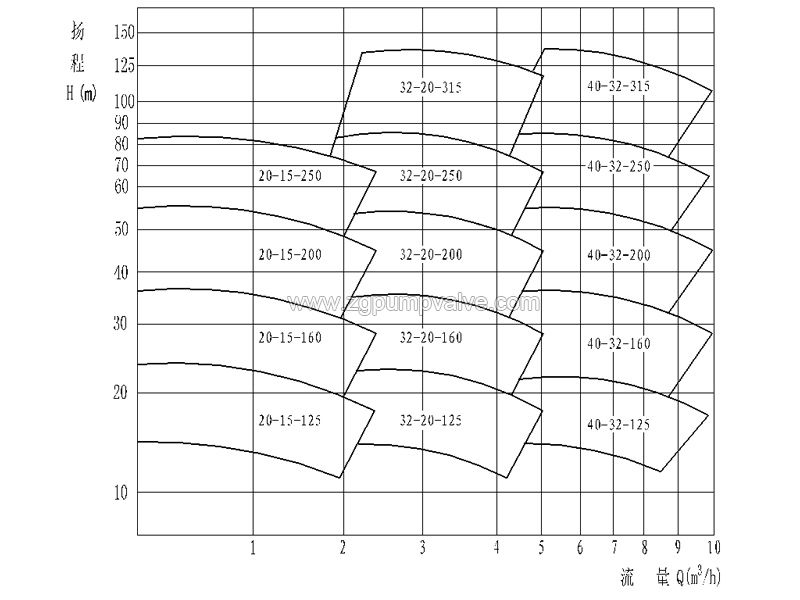

■Flow rate: Q=1.6~6.3 (m³/h)

■Total head: H=20~120 (m)

■Speed: n=1450rpm/2950rpm

■S.g.: γ ≤1.84

■Temperature: T=-20~150℃

■Diameter: 15~32mm

■Comforts to API610, with high reliability, stability and long life.

■Special pump passage design to eliminate loss of second reflux, enables the high efficiency at small flow rate.

■Cone sealing chamber design with good self flush performance, simplified the auxiliary system of the mechanical seal.

■Big capacity oil reservoir and big oil reflux passage prolong the life of bearings.

■Heavy duty shaft design with better strength performance.

■High universalization, standardization and interchangeability

■Various anti-corrosive material for different processes.

■Single stage, single suction, cantilever type chemical centrifugal pump.

■Both foot mounted and centerline mounted structure are available; Radial split casing.

■Bearings are adjustable rotary part installed in the bearing housing.

■Pump outlet on one side of casing.

■Mechanical seal is adopted as the shaft sealing.

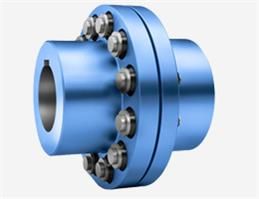

■Direct coupled by claw type couplings or flexible couplings.

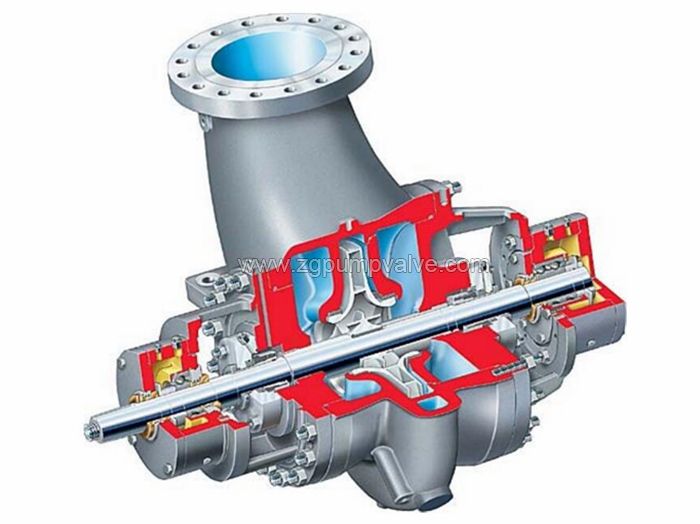

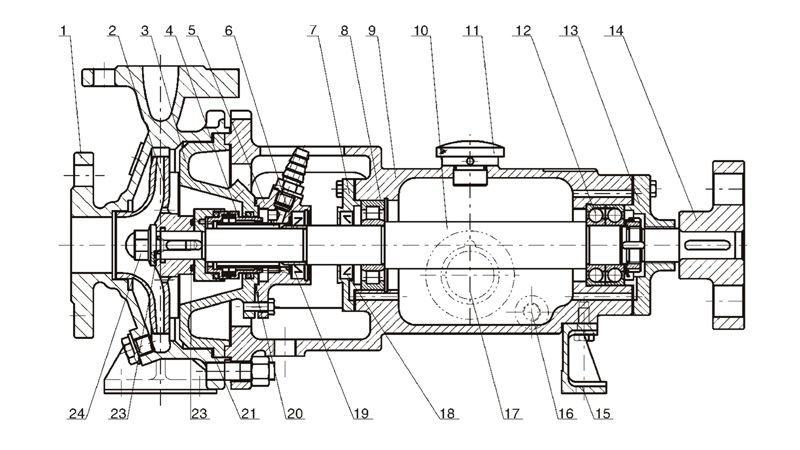

Structure drawing is as blow

1. Pump casing 2. Impeller 3. Pump cover 4. Mechanical seal 5. Seal end gland 6. Wear sleeve 7. Front bearing gland 8. Front bearing | 9. Bearing housing 10. Shaft 11. Air vent cover 12. Back bearing 13. Backing bearing gland 14. Pump coupling 15. Bracket 16. Pipe plug | 17. Oil-analysis standard 18. Skeleton oil seal 19. Skeleton oil seal 20. O ring of seal end gland 21. Pump cover washer/O ring 22. O ring of impeller 23. O ring of impeller nut 24. Impeller nut |

| No. | Descripition | Material | ||||

| CI | Cast steel | Stainless steel | ||||

China standard | ASTM standard | China standard | ASTM standard | |||

| 1 | Pump casing | CS | WCA WCB WCC | ZG1Cr13 ZG2Cr13 ZG00Cr18Ni10 ZG0Cr18Ni9 ZG0Cr18Ni12Mo2Ti ZG0Cr17Ni4CuNb ZG1Cr18Ni9 ZG1Cr18Ni9Ti ZG00Cr17Ni14Mo2 0Cr26Ni5Mo2 0Cr17Mn13Mo2N 00Cr18Ni5Mo3Si2 | CA-15 CA-15M CF-3(SS304L) CF-8(SS304) CF-8M(SS316) CF-3M(SS316L) CN-7M(SS320) CD-4MCu 2205 | |

| 2 | Sealing ring | |||||

| 3 | Impeller | |||||

| 4 | Pump cover | |||||

| 5 | Shaft | Carbon steel, SS420, 2205, SS304, SS316 | ||||

| 6 | Shaft sleeve | SS304, SS316, SS316L, CD4MCu, 2205 | ||||

| 7 | Sealing cover | SS304, SS316, SS316L, CD4MCu, 2205 | ||||

| 8 | Bearing housing | Cast iron | ||||

| 9 | O-rings | Oil-resistent rubber | ||||

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

| Couplings |  | Pin type | Flexible diaphragm coupling |

■Mainly applicable for processes of petrochemical, chemical, synthetic fiber, fertilizer, power plant, metallurgy, food and medicine...

■Suitable to pump clean fluids, fluids of low temperature or high temperature, and corrosive fluids.

Company video

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

+86 28 8218 1182

-

+86 28 8218 1182