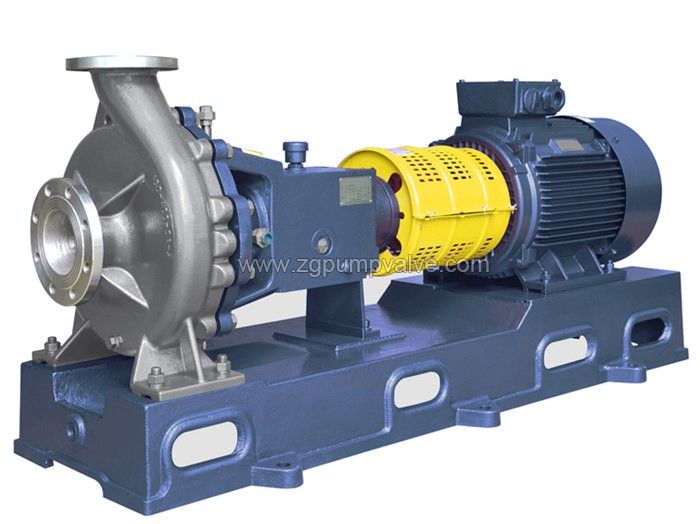

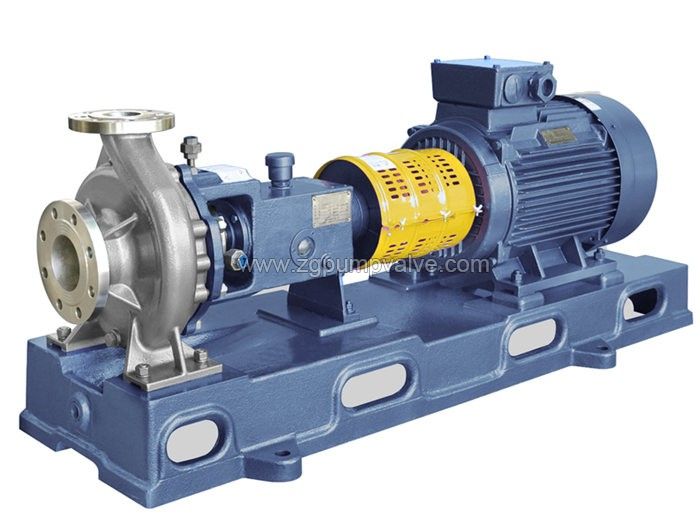

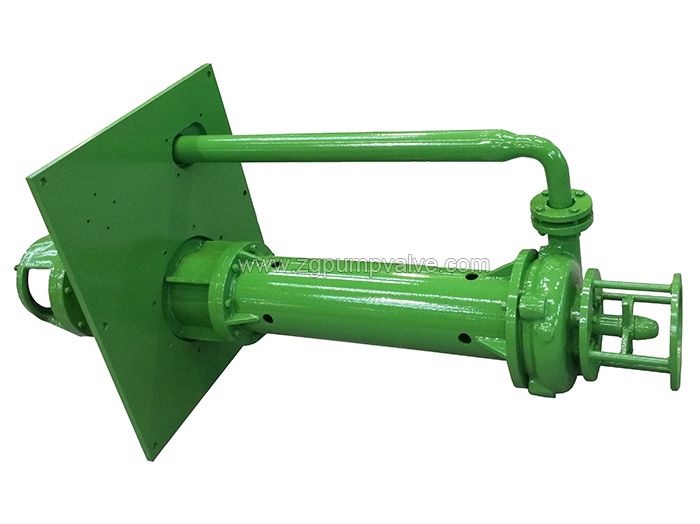

Chemical Pump

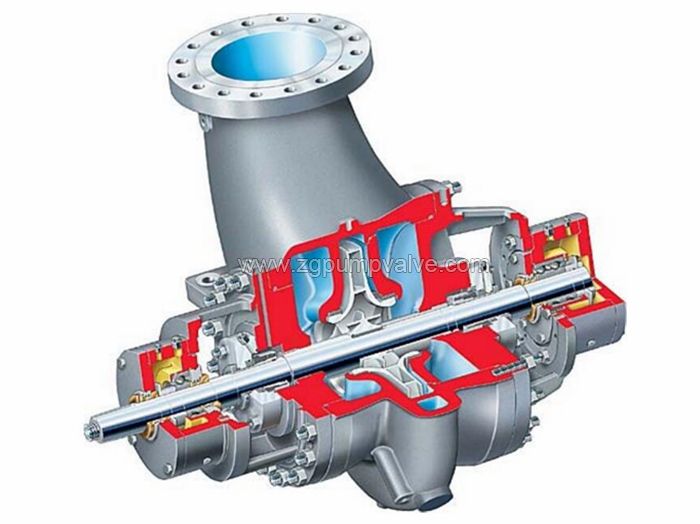

Chemical open impeller pulp pump

The HZJ series open impeller pulp pump(also known as paper pulp pump or pump for paper pulp) is the improved product of the HT series pulp pump, which is a successful design based on long-term technology accumulation and on the experience both in China and overseas advanced technology. The pump has a strong capacity to convey fibre, particle, the pulp below 8% density and other liquid with the solid content below 30%. It can be used in those operating environments in the paper making, metallurgy, fertilizers, salt industry, drainage and power plant, etc.There are various materials available for our open impeller pulp pump, including stainless steel SS304, SS316, SS316L, 904L, duplex stainless steel CD4MCu, 2205, 2507, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

■ Flow rate: Q= 6~1200 (m³/h)

■ Total head: H=5~125 (m)

■ Speed: n=1450/2900rpm

■ Temperature: T=-20~200℃

■ S.g.: γ≤1.85

■ Pump diameter: 50~350mm

■ Using semi-open impeller, has 3 slice;

■ Semi-open, 3 slice impeller, 8%pulp;

■ The impeller is a open impeller, which uses rear blades and wear rings to balance axial forces;

■ The impeller and shaft are connected by a key and locked by a special impeller nut. Eliminates the possibility of impeller nuts becoming loose during operation, shutting down, and backflow;

■ Back-pull design, the rotating part can be removed from the housing without removing the pipe;

■ The sealed cavity is designed with a tapered space to install the mechanical seal into a spacious room. At the same time, the impeller rear blade, the inner surface and the guide blade work together to form a self-flushing flow sealed cavity without any external flushing fluid. Self-flushing flow can quickly eliminate the heat on the friction pair; self-flushing flow can avoid the accumulation of particles (<5%) between the moving ring and the static ring, thereby extending the service life of the mechanical seal.

■ Single-stage single-suction horizontal centrifugal pump structure, the pump cover is fixedly clamped in the middle by the connection between the pump body and the bearing housing, and the pump cover is positioned with the bearing port and the bearing housing;

■ The pump body adopts axial suction, radial discharge, foot support type, and can be directly fixed on the base. The tail of the bearing housing is supported on the base by the suspension bracket;

■ The impeller and the shaft are connected by a key, and a special impeller nut locking method is adopted to prevent the impeller nut from loosening when the medium is poured during operation or stopping the pump;

■ The flushing and cooling interfaces of the pump body, pump cover, bearing housing and sealing end cover are all made of taper pipe thread, which increases the reliability of the pipeline seal. The bearing is made of rolling bearing, oil lubrication, and the oil pool volume is increased;

■ The structure of the pump is designed as a rear door. When the inlet and outlet of the pump are not moved during the inspection (ie, the pump body does not move), the impeller, shaft, shaft seal and bearing components can be removed;

■The large conical cavity of the shaft seal box makes the mechanical seal in a spacious cavity, and also cooperates with the back vane, the guide vane of the inner wall of the cavity, and forms a self-flushing flow field in the shaft seal box, thereby eliminating the need The external flushing fluid is used to achieve self-flushing; the heat generated on the frictional secondary surface is quickly taken away, avoiding the accumulation of solid particles (<5%) in the medium on the contact surface of the rotating ring and the stationary ring, reducing wear and prolonging the machine.

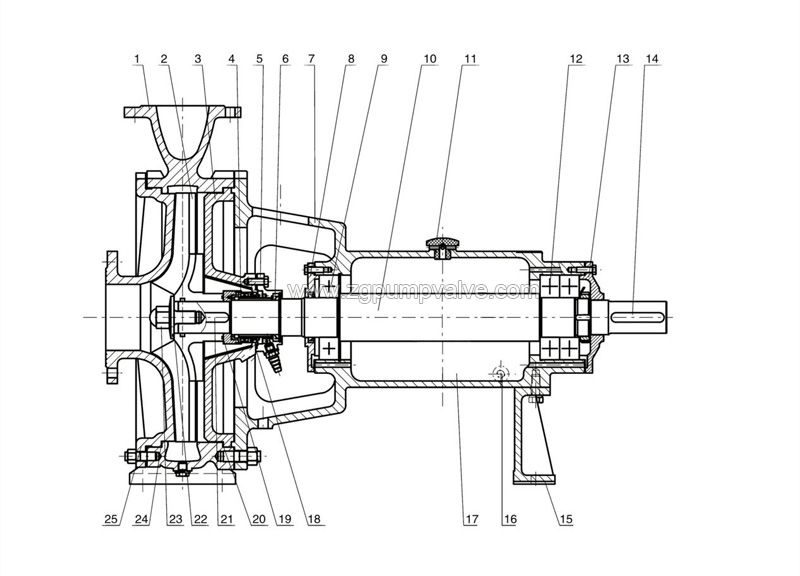

The pump structure is as follows:

| 1.Pump casing 2.Impeller 3.Pump cover 4.Mechanical seal 5.Seal end gland 6.Oil seal 7.Bearing housing 8.Radial bearing end cover | 9. Bearing 10. Shaft 11. Air vent cover 12. Back bearing 13. Trust bearing end cover 14. Key coupling 15. Bracket 16.Pipe plug | 17. Bullseye sight glass 18. O-ring 19. O-ring impeller 20.Gasket of pump cover 21. Key impeller 22. O-ring, impeller nut 23. Impeller nut 24. Gasket of casing 25.Flange |

| No. | Description | Material | |||||

| Anti-corrosion alloy | Cast steel | Stainless steel | |||||

China standard | ASTM standard | China standard | ASTM standard | China standard | ASTM standard | ||

| 1 | Pump casing | 20# Alloy Titanium Nickel 904L Ti/Pd Alloy Monel | Hastelloy Monel Ⅱ-B Ⅱ-C Ni-Resist1 Ni-Resist2 Ni-Resist3 | 25# 35# | WCA WCB | ZG1Cr13 ZG2Cr13 ZG00Cr18Ni10 ZG0Cr18Ni9 ZG0Cr18Ni12Mo2Ti ZG0Cr17Ni4CuNb ZG1Cr18Ni9 ZG1Cr18Ni9Ti ZG00Cr17Ni14Mo2 0Cr26Ni5Mo2 0Cr17Mn13Mo2N 00Cr18Ni5Mo3Si2 | CA-15 CA-15M CF-3(SS304L) CF-8(SS304) CF-8M(SS316) CF-3M(SS316L) CN-7M(SS320) CD-4MCu 2205 |

| 2 | Sealing ring | ||||||

| 3 | Impeller | ||||||

| 4 | Pump cover | ||||||

| 5 | Impeller nut | ||||||

| 6 | Cartridge seal | ||||||

| 7 | Shaft | Carbon steel SS420 2205 SS304 SS316 | |||||

| 8 | Bearing Housing | Cast iron | |||||

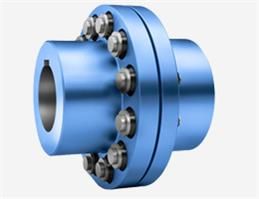

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Mechanical seal |  | Zigong brand | Burgmann, Sihuan Riji, Chengdu Yitong |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

| Couplings |  | Pin type | Flexible diaphragm coupling |

■ Soda and inorganic salts: ammonia salt blending, soda manufactured by ammonia soda process, pure soda, caustic soda manufactured by diaphragm process and ion exchange membrane process, chloride and hypochlorite, soda sulfide, sulfate, hydrogen peroxide, etc;

■ Metallurgy: electrolyte of electrolytic copper and nickel, sodium aluminate liquid for aluminum production, acid for cobalt production, ore slurry for zinc production, ammonium vanadate for vanadium production, acid and thiocarbamide liquid for gold production, etc;

■ Fiber and plastic industries: Dacron, dichloromethane, epichlorohydrin, trichloropropane, PVC, DMF, etc;

■ Paper-making industry: pulp digestion liquor, green liquor, white liquor, concentrated black liquor, bleaching liquor, etc;

■ Chemical fertilizer industry: urea, ammonium nitrate, ammonium bicarbonate, ammonium chloride, ammonium phosphate, potassium chloride, potassium sulfate, etc.

Company video

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

+86 28 8218 1182

-

+86 28 8218 1182