Chemical Pump

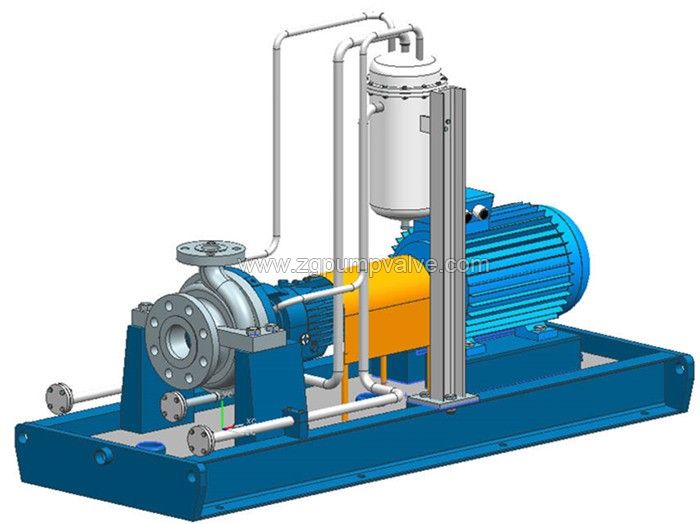

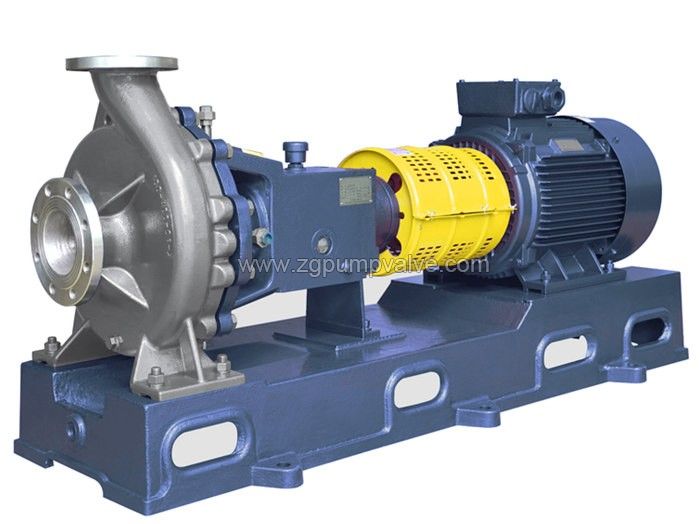

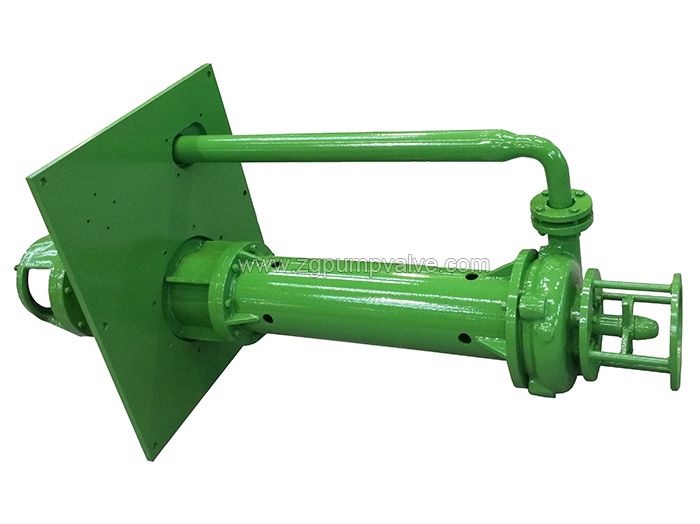

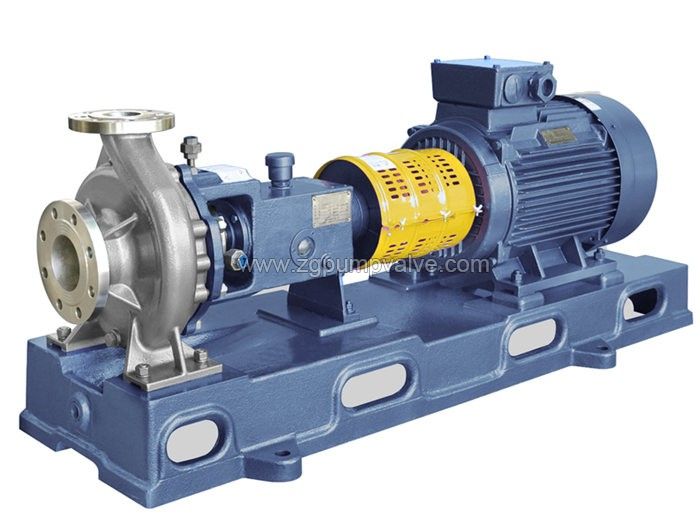

Petrochemical process pump

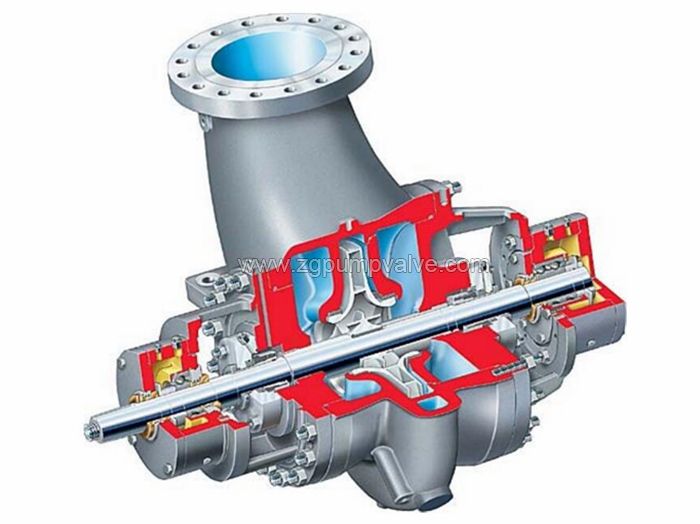

ZH series petrochemical process pump is developed according to the producing requirements of petrochemical industry, and it is OH2 structure(centerline mounted) type which conforms to API610(ISO13709) standard. There are elaborately designs on the mounting, connection, cooling and mechanical seal... Monitor system can be configurated. It is suitable to pump clean fluids, fluids with particles, flammable, explosive and corrosive fluids.There are various materials available for our petrochemical process pump, cast iron, stainless steel SS304, SS316, SS316L, 904L, duplex stainless steel CD4MCu, 2205, 2507, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

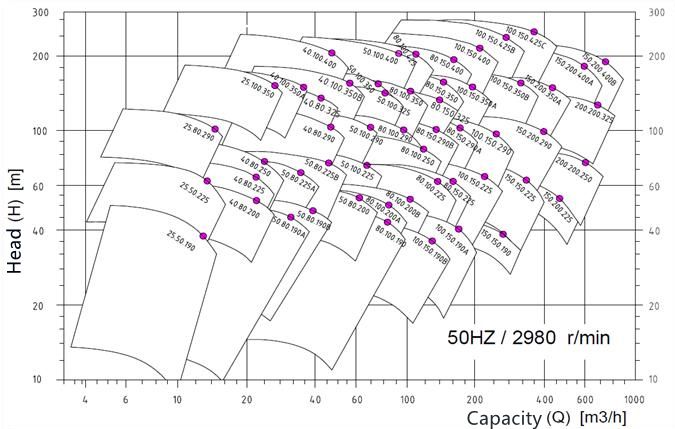

■ Flow rate: Q=4~2500 (m³/h)

■ Total head: H=3~300 (m)

■ Speed: n=1450/2900rpm

■ Temperature: T=-80~425℃

■ S.g.: γ≤1.85

■ Pump diameter: 50~350mm

■ Max. pressure: 7.5Mpa

■ Conforms to API610 10thAPI 11th standard, with high reliability and long lifetime;

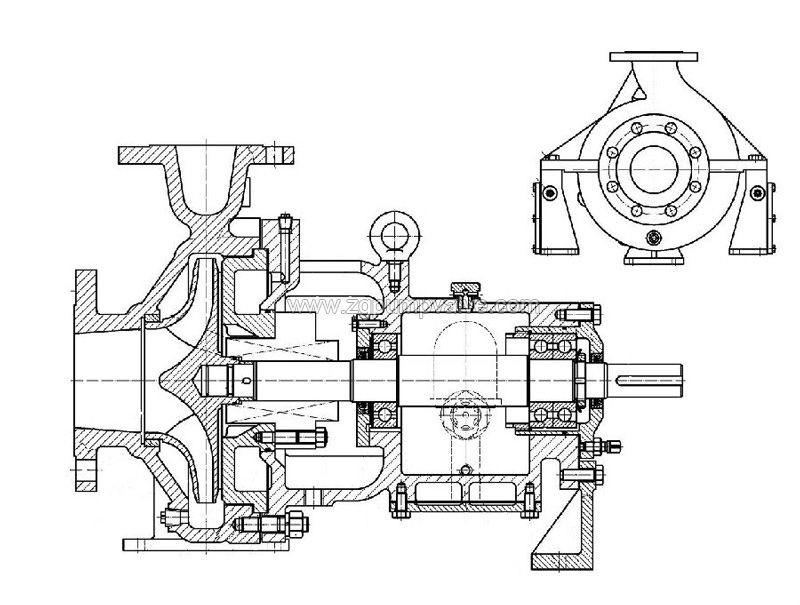

■ Shaft diameter enlarged, shafting stability coefficient (L3/D4) 9.3~83;Small flexibility of mechanical seal, axial movement of shaft is less than 0.05mm;

■ Impeller is precisely casted, which dynamic balance up to G2.5; High universalization and standardization. Pump casing is non-interchangeable because of different pressure, other parts are all interchangeable.

■ Shaft sealing conforms to API682 2th edition standard.

■ Patent product non-contact and non-sparking oil sealing, which prevents the entry of water into the oil reservoir.

■ Monitor system can be configurated, which including the monitoring of pump vibration, bearing temperature rising, pressure at the pump inlet and outlet, flow rate, loading at the driving end.

■ Single stage,cantilever type petrochemical process pump,horizontal center line mounted. Dual volute casing design for pump outlet diameter above 80 mm.

■ Cooling jacket and steam jacket is available.

■ Space of sealing chamber conforms to the requirements of API682 standard, there’s enough room for tandem type and double mechanical seal.

■ Based on different application, the bearing housing can be configurated with water cooling, air cooling or heater.

■ Back pull design, the rotary part can be removed out from casing without dismantle the pipelines.

Structure drawing is as below

| No. | Description | Material | |||||

| Anti-corrosion alloy | Cast steel | Stainless steel | |||||

China standard | ASTM standard | China standard | ASTM standard | China standard | ASTM standard | ||

| 1 | Pump casing | 20# Alloy Titanium Nickel 904L Ti/Pd Alloy Monel | Hastelloy Monel Ⅱ-B Ⅱ-C Ni-Resist1 Ni-Resist2 Ni-Resist3 | 25# 35# | WCA WCB | ZG1Cr13 ZG2Cr13 ZG00Cr18Ni10 ZG0Cr18Ni9 ZG0Cr18Ni12Mo2Ti ZG0Cr17Ni4CuNb ZG1Cr18Ni9 ZG1Cr18Ni9Ti ZG00Cr17Ni14Mo2 0Cr26Ni5Mo2 0Cr17Mn13Mo2N 00Cr18Ni5Mo3Si2 | CA-15 CA-15M CF-3(SS304L) CF-8(SS304) CF-8M(SS316) CF-3M(SS316L) CN-7M(SS320) CD-4MCu 2205 |

| 2 | Sealing ring | ||||||

| 3 | Impeller | ||||||

| 4 | Pump cover | ||||||

| 5 | Impeller nut | ||||||

| 6 | Cartridge seal | ||||||

| 7 | Shaft | Carbon steel SS420 2205 SS304 SS316 | |||||

| 8 | Bearing Housing | Cast iron | |||||

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Mechanical seal |  | Zigong brand | Burgmann, Sihuan Riji, Chengdu Yitong |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

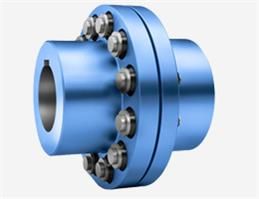

| Couplings |  | Pin type | Flexible diaphragm coupling |

ZH series petrochemical process pump is suitable for pumping mineral acid solutions, organic acid solutions, brines, petrochemical solutions, organic compounds and other corrosive raw materials and products. It is mainly used in the below sections.

■ Multiple evaporation and MVR evaporation process

■ Refinery, petrochemical industries, coal chemical industries and low temperature projects

■ Chemical industry, paper making industry, pulp industry, sugar making and other general process industries.

■ Water plant, seawater desalinization

■ Power plant

■ Environment protection

■ Vessel and at sea industries.

Company video

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

+86 28 8218 1182

-

+86 28 8218 1182