Chemical Pump

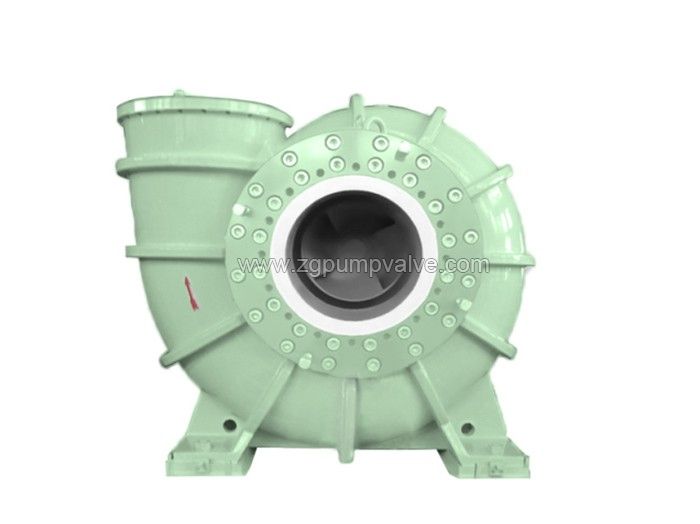

SiC silicon carbide ceramic lined desulfurization pump

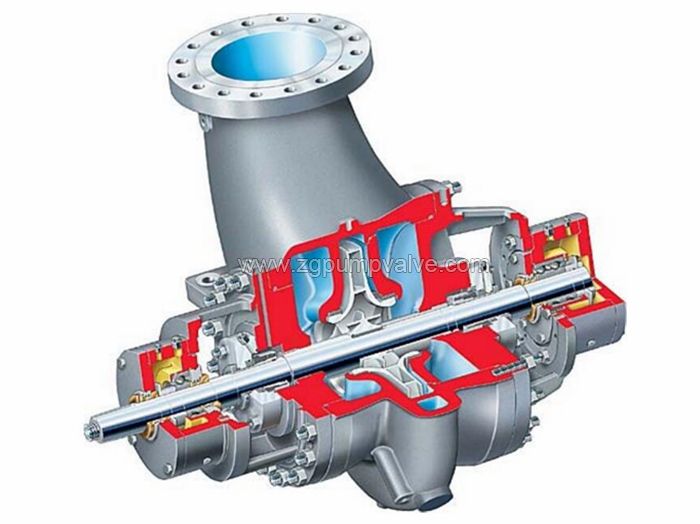

Ceramic lined recirculation desulphurization pumps own features of high efficiency, wear resistance, corrosion resistance and impact resistance. The flow parts are made of metal skeleton lined with silicon carbide composite ceramic material, which has strong corrosion resistance and can withstand any environment with PH value 1 ~ 14. Silicon carbide material has extremely high hardness, strong flexibility and crack resistance. Adopting the structure of horizontal mixed flow pump, with large flow rate, middling head, high efficiency, simple structure, silicon carbide ceramic lined desulfurization pump is suitable for conveying corrosive medium containing particles. It is widely used as desulfurization pumps in wet flue gas desulfurization process.

Based on the high efficiency hydraulic model of metal horizontal mixed flow pump, combined with ceramic-metal composite manufacturing technology, achieve the goal of manufacturing a high-efficiency desulphurization pump with corrosion resistance and wear resistance.

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

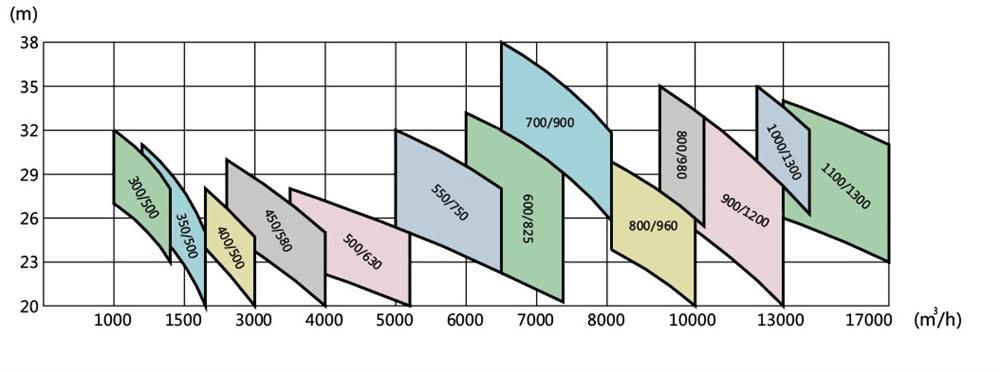

Flow rate: Q=500-17000m3/h

Total head: H=18-80m

Pump diameter: φ=300-1100mm

Efficiency: η≥82%

Speed: 195-1450r/min

Temperature: T≤200℃

■ The flow parts are all lined corrosion-resistant and abrasion-resistant silicon carbide ceramic materials.

■ The lining process adopts a new silicon carbide ceramic vacuum casting technology, the metal skeleton and composite materials have strong bonding force, and have a certain impact resistance.

■ The impeller and wear plate are vacuum cast by silicon carbide ceramic which have actual working life more than 60000 hours, and the overall lifetime of ceramic circulating desulfurization pump is as high as 100,000 hours.

■ The impeller consists of a metal impeller skeleton + silicon carbide ceramic composite material. It not only meets the requirements of wear resistance and corrosion resistance, but also ensures that the connection with the drive shaft is firm and reliable.

■ The horizontal mixed-flow ceramic recirculation pump adopts the pull back structure, which is convenient for the disassembly and assembly of the impeller, mechanical seal and shaft, and does not need to disassemble the import and export pipeline of the pump.

■ The impeller could be adjusted axially to adjust the best position in the pump chamber to ensure that the operation of the pump is always in an efficient and stable state.

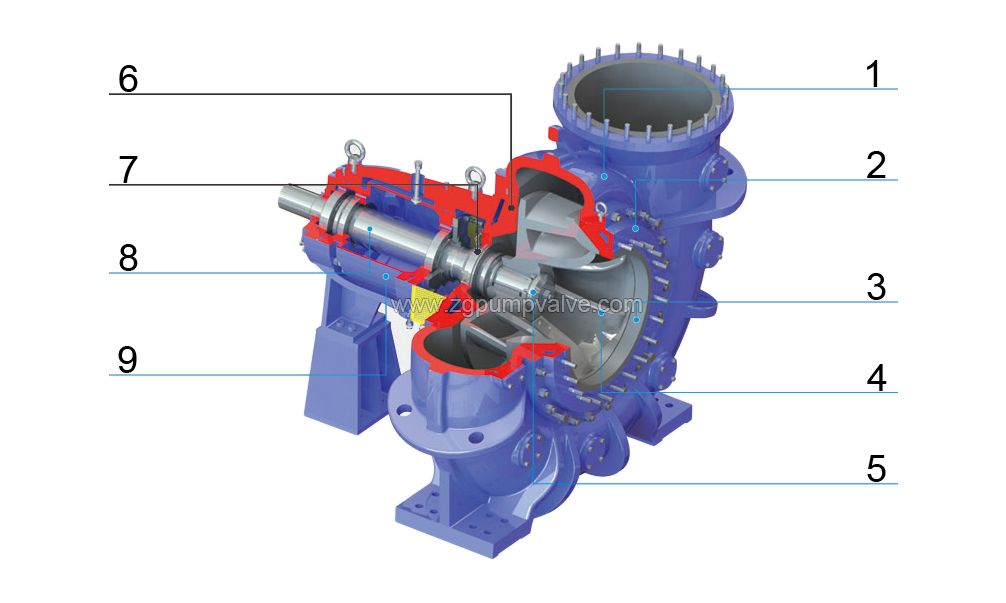

| 1.Pump body | 2.Pump gland | 3.Wear plate | 4.Impeller | 5.Impeller lock |

| 6.Rear pump cover | 7.Mechanical seal | 8.Shaft | 9.Transmission assembly |

■ The liner of flow parts are all made from corrosion-resistant and high-abrasive silicon carbide ceramic materials. The ceramic parts using vacuum casting process have characteristics of extremely high hardness, strong flexibility, crack resistance, strong wear resistance, chemical resistance, strong oxidation resistance, and small thermal expansion coefficient.

■ The material of the volute, impeller and front and rear plate of the pump is divided into two categories: condensation curing ceramics and high temperature sintering engineering ceramics. (silicon carbide /Sic, alumina /Al2O3, zirconia /ZrO2 and silicon nitride /Si3N4).

■ Pump body: the pump shell is made from high strength ductile cast iron, and liner of flow parts is silicon carbide ceramic composite material;

■ Impeller: the metal impeller skeleton + silicon carbide ceramic composite material;

■ Pump gland: the parts that are not in contact with the medium are made from metal, and the material can be selected, : cast iron, carbon steel, stainless steel, SS304/SS316/SS316L, duplex stainless steel, CD4MCu, 2205, 2507, etc.;

■ Rear pump cover: the outer of the pump cover is made from cast iron or carbon steel, and liner of flow parts is silicon carbide ceramic composite material;

■ Shaft: The shaft is rigid design, and the material can be selected,: 2205, 3Cr13, 40Cr, 42CrMo and other high-strength alloy steel shaft.

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Mechanical seal |  | Zigong brand | Burgmann, Sihuan Riji, Chengdu Yitong |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

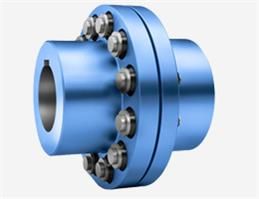

| Couplings |  | Pin type | Flexible diaphragm coupling |

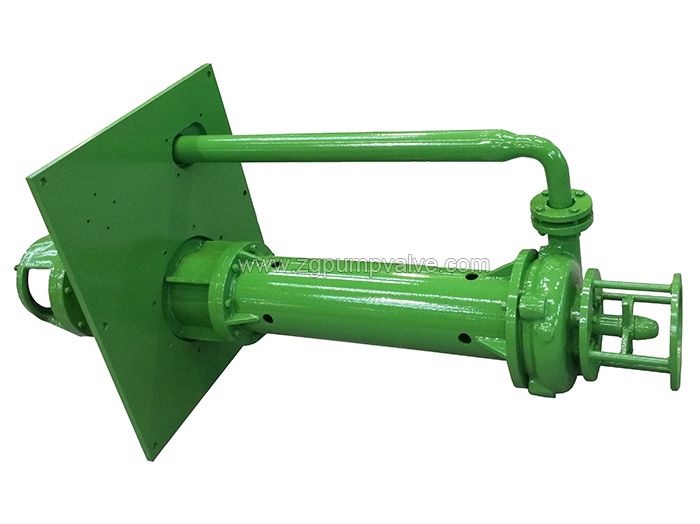

■ Suitable for FGD limestone-gypsum wet flue gas desulfurization process, used as a desulfurization pump;

■ Suitable for double alkali process and ammonia water desulfurization process.

■ Widely used in power, mining, metallurgy, chemical and other industries, is flue gas desulfurization, phosphorus chemical, coal chemical, petrochemical, alumina and other industries;

■ Widely used in high strength, high toughness and high hardness harshest conditions. Corrosion-resistant wear-resistant mixed-flow pumps must be used under any harsh conditions.

Company video

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

+86 28 8218 1182

-

+86 28 8218 1182