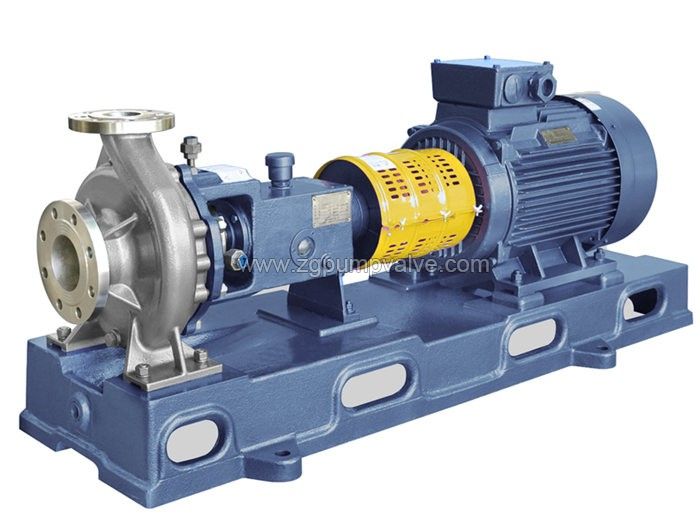

Chemical Pump

Single drive hydraulic turbine pump

By making use of the remaining energy to realize the energy conversion to drive ZHT series single drive hydraulic turbine pump which loads recoverable energy with high recovery efficiency. The turbine pump and the load are direct driven without overdrive clutch and full power motor, which is more reliable and with small occupied room, with the features of low investment and maintenance costs, and the DCS control is simple and reliable.There are various materials available for our single drive turbine pump, including stainless steel SS304, SS316, SS316L, duplex stainless steel, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

■ Flow rate:Q= 420~2600 m³/h

■ Total Head:H=120~640 m

■ Speed:n=2970 r/min

■ Temperature:T=-20~250 ℃

■ Products comply with API610 standards, shaft seal system meets the API682 standard.

■ With thickened heavy shaft design, strong shaft and bearing loading ability, long service life.

■ With high turbine efficiency and full energy recovery.

■ The turbine and the load are direct drive, with small occupied area and low investment and maintenance costs.

■ DCS control is simple and reliable.

■ The turbine can be safe operation when it gets over 10% of the rated speed, and the system can fully recover the surplus energy.

■ There are many flushing options for mechanical seal and selecting the domestic famous manufacturers of mechanical seal with reliable sealing and long service life.

■ Turbine is stable operation with low noise.

■ ZHT hydraulic turbine is divided into three types:

(1) ZHT single stage single suction cantilever center support type OH2 structure;

(2) ZHT (S) single stage double suction type BB2 structure;

(3) ZHT (D) multistage single suction self balance center support type BB4 structure.

■ All turbines are upper-inlet and upper-outlet.

■ All turbines are center support suitable for high temperature medium.

■ All bearings adopt water cooling structure, to improve the service life of bearings.

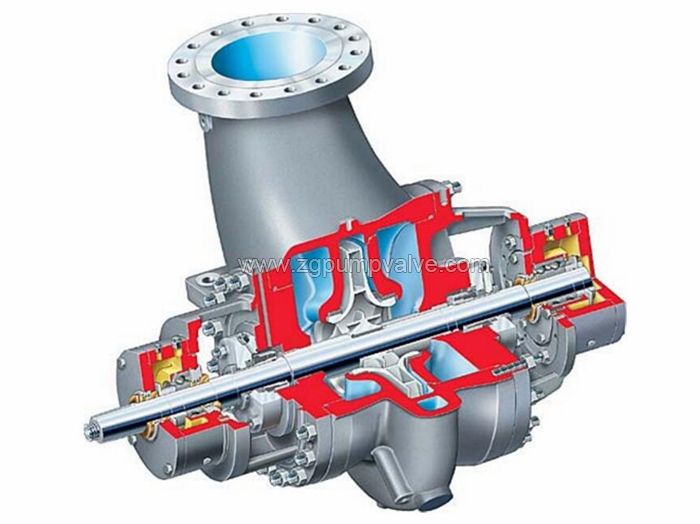

Structure drawing is as below

Structure drawing of type ZHT (OH2)

1. Outlet elbow 2. Pump body 3. Impeller nut 4. Seal ring 5. Impeller 6. Pump cover 7. Mechanical seal 8. Front bearing cover 9. Front bearing 10. Bracket 11. Shaft 12. Back bearing 13. Back bearing cover 14. Round nut 15. Suspension support 16. Cooling pipe 17. Oil leveler 18. Pump body support

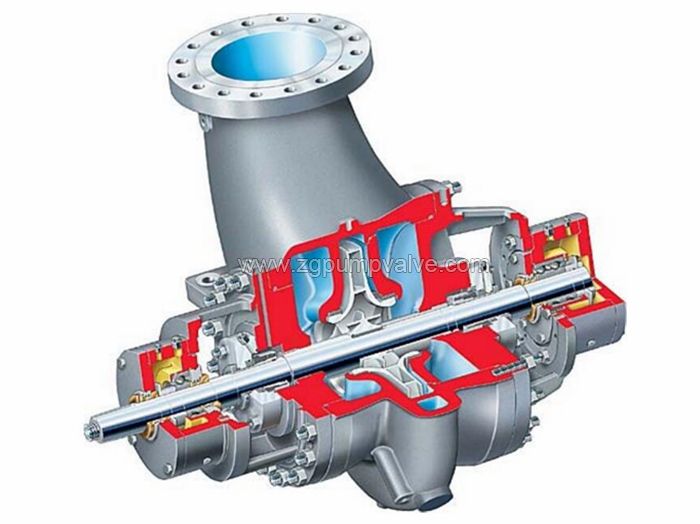

Structure drawing of type ZHT(S) (BB3)

1. Bearing cover 2. Bearing 3. Bearing box 4. Middle fame 5. Pump body 6. Seal ring 7. Impeller 8. Shaft sleeve 9. Mechanical seal 10. Dust-proof plate 11. Shaft 12. Round nut 13. Oil extraction ring sleeve 14. Oil extraction ring 15. Bearing 16. Oil sling shaft sleeve 17. Throttling sleeve 18. Pump support

Structure drawing of type ZHT(D) (BB4)

1. Dust-proof plate 2. Bearing cover 3. Bearing body 4. Bearing 5. Discharge sectionⅡ 6. Mechanical seal 7. Throttling ring 8. Middle section 9. Water diversion pipe 10. Inlet section 11. Guide vane 12. Discharge sectionⅠ 13. Support 14. Bearing cover 15. Oil flinger 16. Return pipe 17. Inlet elbow 18. Turbine support 19. Mechanical seal house 20. Spiral sleeve 21. Throttling sleeve at high voltage end 22. Seal ring 23. Impeller throttling ring 24. Impeller 25. Middle spiral sleeve 26. Middle throttling sleeve 27. Final-stage guide vane 28. Middle shaft sleeve 29. Snap ring 30. Shaft

API610 standard grade:

■ C-6

■ A-7

■ A-8

■ D-1

■ D-2

■ And other material combination.

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Mechanical seal |  | Zigong brand | Burgmann, Sihuan Riji, Chengdu Yitong |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

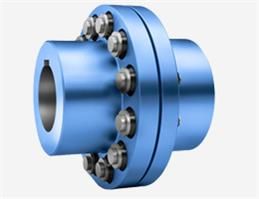

| Couplings |  | Pin type | Flexible diaphragm coupling |

ZHT single drive hydraulic turbine is suitable for delivering pure liquid or with small amount of small particles, neutral or corrosive medium. Mainly used:

■ Decarbonization process of synthetic ammonia unit

■ Desulfurization unit of natural gas purification plant

■ Residuum hydro desulfurization unit in refinery

■ Hydrocracking of high pressure hydrogenation unit in petrochemical plant

■ Residual pressure recovery device of reverse osmosis desalination system

Company video

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

+86 28 8218 1182

-

+86 28 8218 1182