Chemical Pump

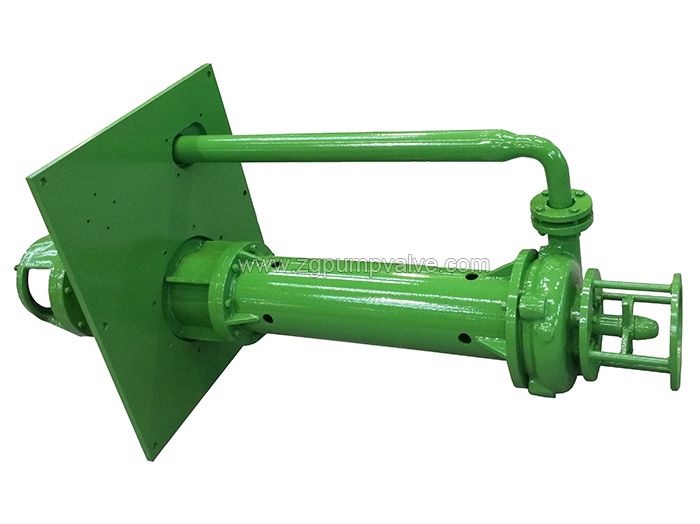

Vertical axial/mixed flow chemical pump

ZLH series vertical axial(mixed) flow pump is also known as salting out vertical axial flow pump and low temperature crystallization axial flow pump. The impeller and elbow passage of ZLH series vertical axial flow pump are optimized design with better performance and efficiency.

This vertical axial flow pump is a vertical single stage and axial flow structure, suitable for working conditions of large capacity small head which has the characteristics of large flow, long lifetime, good performance of anti- cavitation, stable operation and easy installation and maintenance.

There are various materials available for our vertical axial flow pump, including stainless steel SS304, SS316, SS316L, 904L, duplex stainless steel CD4MCu, 2205, 2507...

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

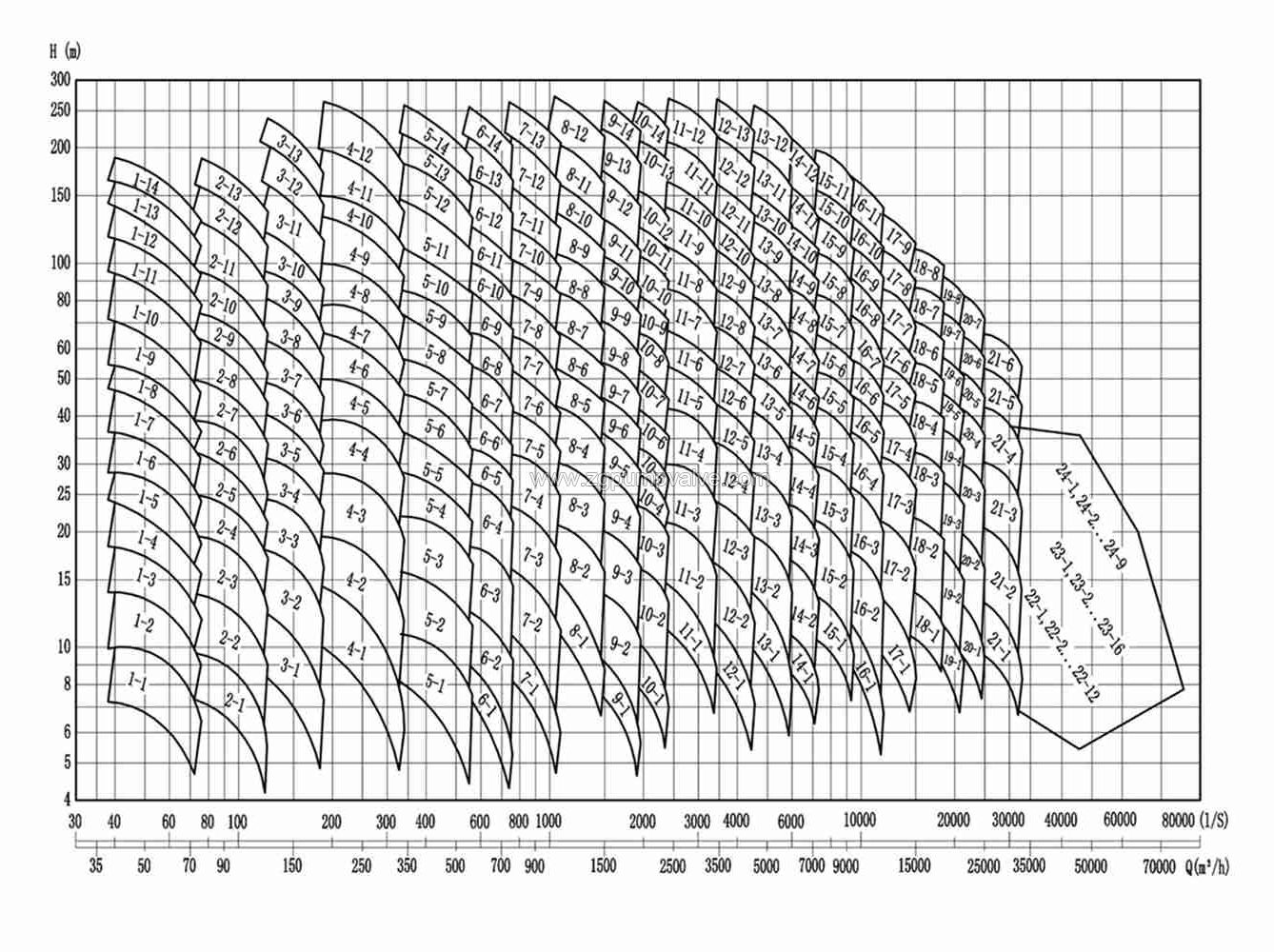

■ Flow rate: Q=300~8000 (m³/h)

■ Total head: H= 1~300 (m)

■ Speed: n=180-1450rpm

■ Fluid temperature: T= 0~50℃

■ Fluid s.g.: γ≤1.4

Optimized elbow passage of better hydraulic performance.

Adjustable impeller of high efficiency and wide high efficiency zone.

Slowly pump speed design conforms to the technological requirements of salting out and low temperature crystallization.

Vertical axial flow pumps are widely used in saltworks, obtaining salt by evaporating brine, composite alkali process, etc. Selecting corrosion-resistant materials and high-strength shafts to ensure smooth operation and long service life of vertical axial flow pumps. The diameter of suction bowl of the vertical axial flow pump is from 225mm to 3100mm, so it has a wide range of applications.

Specially designed to suit different applications. With the help of our professional engineers, special design could be carried out to increase the head, increase the guide vane body, and realize the function of a vertical mixed-flow pump; Wear resistant coating is added to the impeller for the medium containing corrosive and hard particles, so that the service life of the vertical pump is greatly extended. Increasing the system pressure and liquid level can achieve the purpose of forced circulation.

■ The impeller of the vertical axial flow pump is immersed in fluid, the pump and the motor are installed on different structural layers, the pump body is installed on the basis of the pump layer, the weight of the vertical axial pump body is bear by the pump foundation, and all the axial force of the lifting fluid is bear by the axial thrust bearing in the transmission device.

■ It could also add the connection structure between the pump outlet pipe and the motor base according to the site conditions. Relying on the mechanical positioning between the structures ensures the concentric motor shaft and pump shaft, and realize that the motor base bears all the self-weight load and axial force. During installation and maintenance, the vertical axial flow pump can be lifted out and lowered from the mounting hole on the motor floor of the pump house, and installation and disassembly are completed on the motor floor without entering the pool below the pump house.

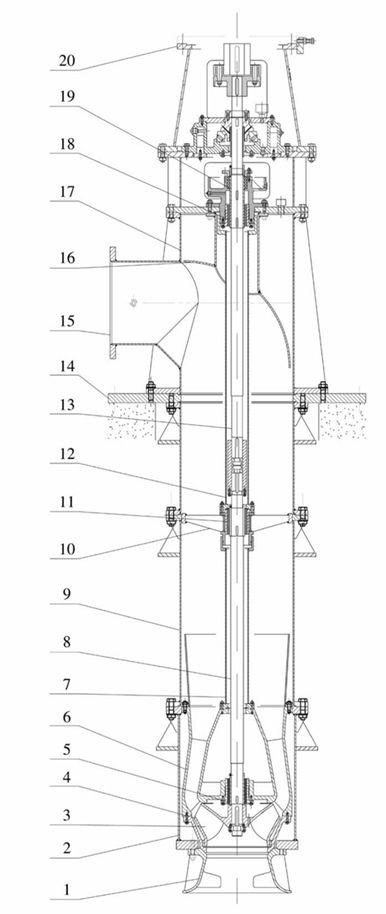

Structure drawing is as below:

1. Suction bell 2. External column (lower) 3. Impeller house 4. Impeller 5.Guide bearing (lower) 6.Diffuser casing 7.Internal column (lower) | 8. Shaft (lower) 9. External column (middle) 10.Bearing bracket 11.Guide bearing (middle) 12.Internal column (upper) 13.Shaft (upper) 14.Supporting plate | 15.Discharge elbow 16.Guide vane 17.External column (upper) 18.Guide bearing (upper) 19.Stuffing box 20.Motor support |

Vertical axial flow pumps are used for large flow, low head occasions, for salt works, alkali-making, obtaining salt by evaporating seawater etc., choose stainless steel, SS304, SS316, SS316L, duplex stainless steel, CD4MCu, 2205, 2507, 904L, and other corrosion resistant materials. For the medium containing particles, sand or other hard impurities, choose wear-resistant materials, wear-resistant cast iron, carbon steel and other materials.

| No. | Description | Material | |||||

| Anti-corrosion alloy | Cast steel | Stainless steel | |||||

China standard | ASTM standard | China standard | ASTM standard | China standard | ASTM standard | ||

| 1 | Pump casing | 20# Alloy Titanium Nickel 904L Ti/Pd Alloy Monel | Hastelloy Monel Ⅱ-B Ⅱ-C Ni-Resist1 Ni-Resist2 Ni-Resist3 | 25# 35# | WCA WCB | ZG1Cr13 ZG2Cr13 ZG00Cr18Ni10 ZG0Cr18Ni9 ZG0Cr18Ni12Mo2Ti ZG0Cr17Ni4CuNb ZG1Cr18Ni9 ZG1Cr18Ni9Ti ZG00Cr17Ni14Mo2 0Cr26Ni5Mo2 0Cr17Mn13Mo2N 00Cr18Ni5Mo3Si2 | CA-15 CA-15M CF-3(SS304L) CF-8(SS304) CF-8M(SS316) CF-3M(SS316L) CN-7M(SS320) CD-4MCu 2205 |

| 2 | Sealing ring | ||||||

| 3 | Impeller | ||||||

| 4 | Pump cover | ||||||

| 5 | Impeller nut | ||||||

| 6 | Cartridge seal | ||||||

| 7 | Shaft | Carbon steel SS420 2205 SS304 SS316 | |||||

| 8 | Bearing Housing | Cast iron | |||||

As the column length of vertical axial flow pumps is determined by the customers, so those vertical line shaft pumps are in fact tailor made products with different configurations:

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Mechanical seal |  | Zigong brand | Burgmann, Sihuan Riji, Chengdu Yitong |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

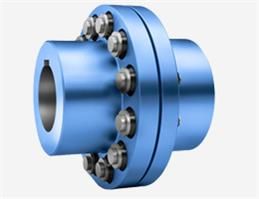

| Couplings |  | Pin type | Flexible diaphragm coupling |

Due to the features of large flow and low head, our vertical axial flow pumps can widely used in below applications:

ZLH series is suitable for applications of big flow with low total head. The cast iron vertical axial pumps are used for agricultural drainage and irrigation, urban water supply, drainage, thermal power station water transmission.

ZLH series is able to pump clean water, sewage water with small particles and chemical process fluids with small particles.

ZLH series is especially suitable for salting out and low temperature crystallization of combined soda process.

Salt works, phosphoric acid, obtaining salt by evaporating seawater and other chemical industries

Company video

-

Solución de Problemas en Bombas Sumergibles: Guía Definitiva 2025

-

End Suction Pump vs. Inline Pump: What Are The Differences?

-

Vertical Seawater Pumps Run At Optimal Hydraulic Efficiency Steadily

-

Duplex stainless steel centrifugal pumps vs titanium centrifugal pumps: The best choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

Solución de Problemas en Bombas Sumergibles: Guía Definitiva 2025

-

End Suction Pump vs. Inline Pump: What Are The Differences?

-

Vertical Seawater Pumps Run At Optimal Hydraulic Efficiency Steadily

-

Duplex stainless steel centrifugal pumps vs titanium centrifugal pumps: The best choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

+86 28 8218 1182

-

+86 28 8218 1182