Chemical Pump

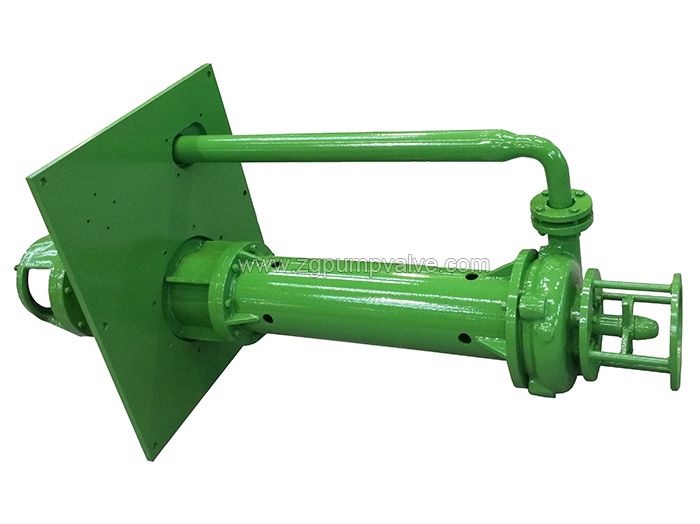

Vertical high temperature molten salt pump

High temperature molten salt pumps are vertical long shaft structure, used for conveying high temperature molten salt medium. According to the working condition, there are two structural forms to choose. Advanced bearing cooling system and strengthen shaft ensure long service life. In addition to handle molten salt, this pump could be used for conveying other high temperature chemical medium. The maximum temperature is 850℃, and it has a wide range of application.

-

Parameters

-

Features

-

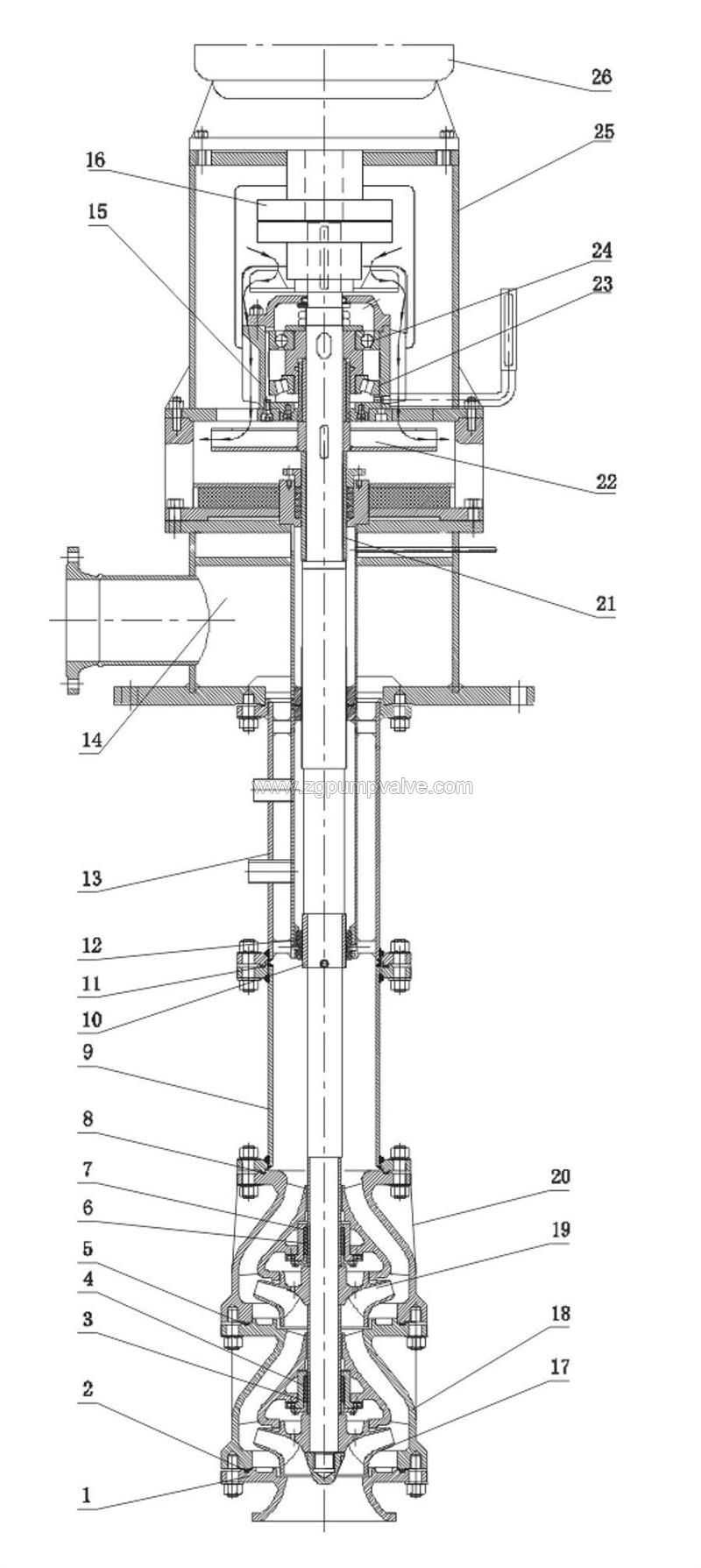

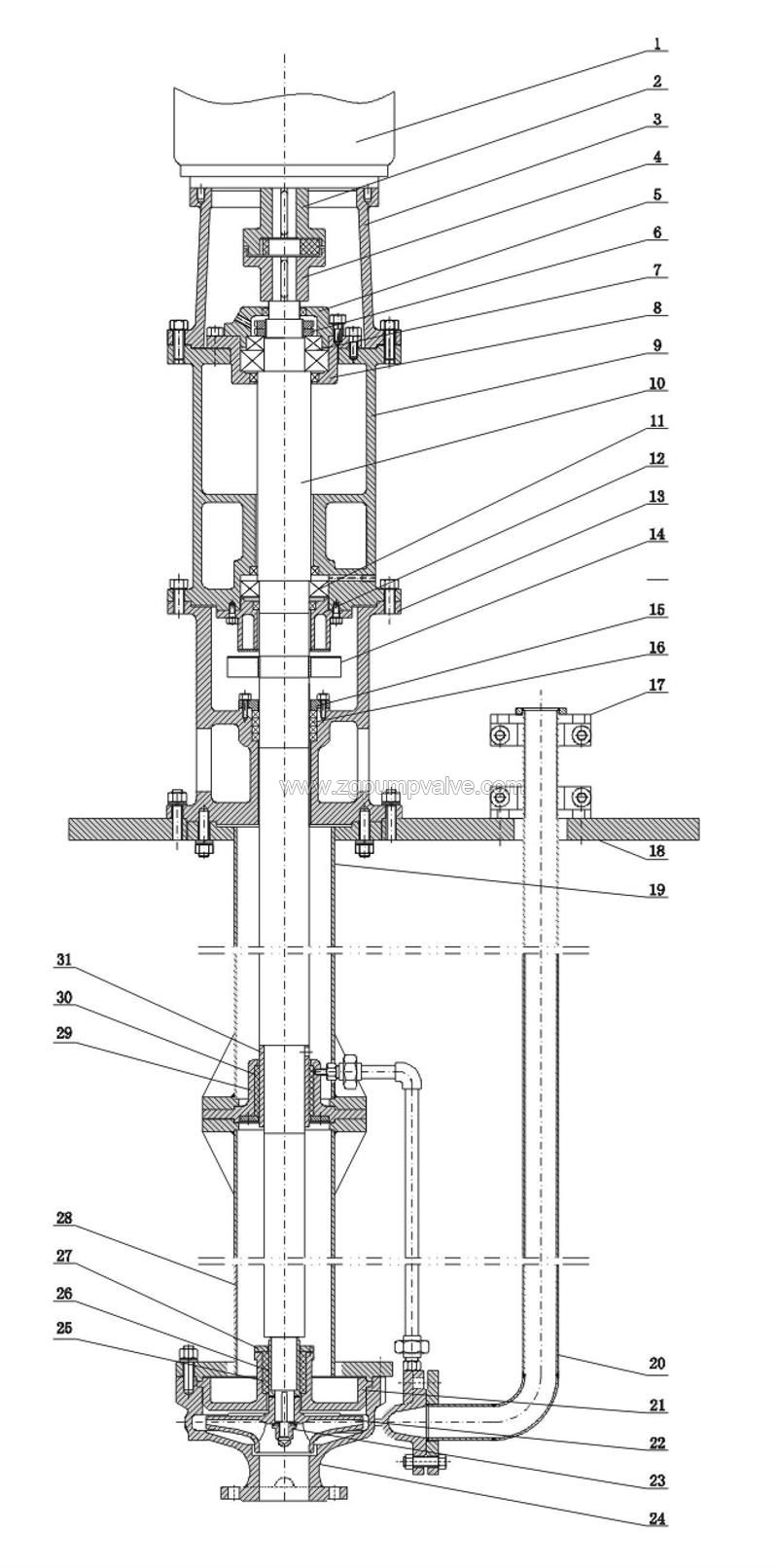

Structure

-

MOC

-

Configuration

-

Application

-

Performance

Flow rate:Q=2~1600 (m³/h)

Max. head:H=350 (m)

Max. temperature:T=850℃

Max. pressure:7.5Mpa

1. The multi-stage molten salt pump has high head and high pressure

2. Bearing part is equipped with cooling device, bearing working environment does not keep the influence of high temperature medium, bearing long service life

3. Structure optimization, ensure that the cooling water absolutely does not enter the medium

4. The sealing device is reliable, the saturated steam of the conveying medium will not escape

5. Two forms of structure

6. In addition to the molten salt, could transport other high temperature medium, as a high temperature chemical transfer pump, and the maximum temperature of the medium is 850℃

7. Completely eliminate heat transfer to the transmission parts, long service life

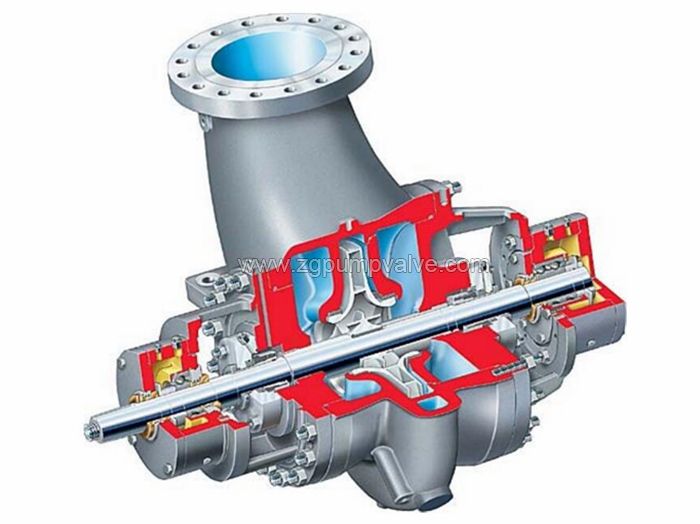

1.Suction section 2.Gasket 3.Interstage shaft sleeve 4.Lower bushing 5.Gasket 6.Interstage shaft sleeve 7.Lower bushing 8.Joint gasket 9.Lower joint | 10.Intermediate shaft sleeve 11.Joint gasket 12.Intermediate bushing 13.Upper joint pipe 14.Discharge section 15.Transmission components 16.Coupling 17.Impeller 18.Pump body | 19.Impeller 20.Pump body 21.Packing shaft sleeve 22.Fan 23.Bearing 24.Bearing 25.Motor frame 26.Motor |

1.Motor 2.Motor coupling3.Motor frame 4.Pump coupling 5.Upper bearing gland 6.Round nuts 7.Upper bearing 8.Bearing box 9.Bearing frame 10.Pump shaft 11.Lower bearing | 12.Lower bearing gland 13.Intermediate frame 14.Fan 15.Packing seal 16.Packing 12×12 17.Split half flange 18.Base Plate 19.Upper joint pipe 20.Discharge pipe 21.Pump cover 22.Impeller | 23.Impeller nut 24.Pump body 25.Lower bushing 26.Lower shaft sleeve 27.Bushing gland 28.Lower joint pipe 29.Guide bearing body 30.Upper bushing 31.Upper shaft sleeve |

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Mechanical seal |  | Zigong brand | Burgmann, Sihuan Riji, Chengdu Yitong |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

| Couplings |  | Pin type | Flexible diaphragm coupling |

Transport all kinds of high temperature molten salt, high temperature molten slag, liquid lead, high temperature molten aluminum and other high temperature media.

■ Chemical industry, melamine, salt, alkali, urea

■ Energy industry: Nuclear power plant, concentrating solar power plant

■ Phthalic anhydride, maleic anhydride, acrylic acid, fluorine chemical, refrigerant, alumina, organic chemical and other industries of high temperature medium transport or thermal shift conditions

■ Membrane method to fix alkali, organic fluorine cracking used two - and three-component molten salt

■ High temperature fluid transport for phosphate fertilizer, oil cracking and other devices

Company video

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

+86 28 8218 1182

-

+86 28 8218 1182