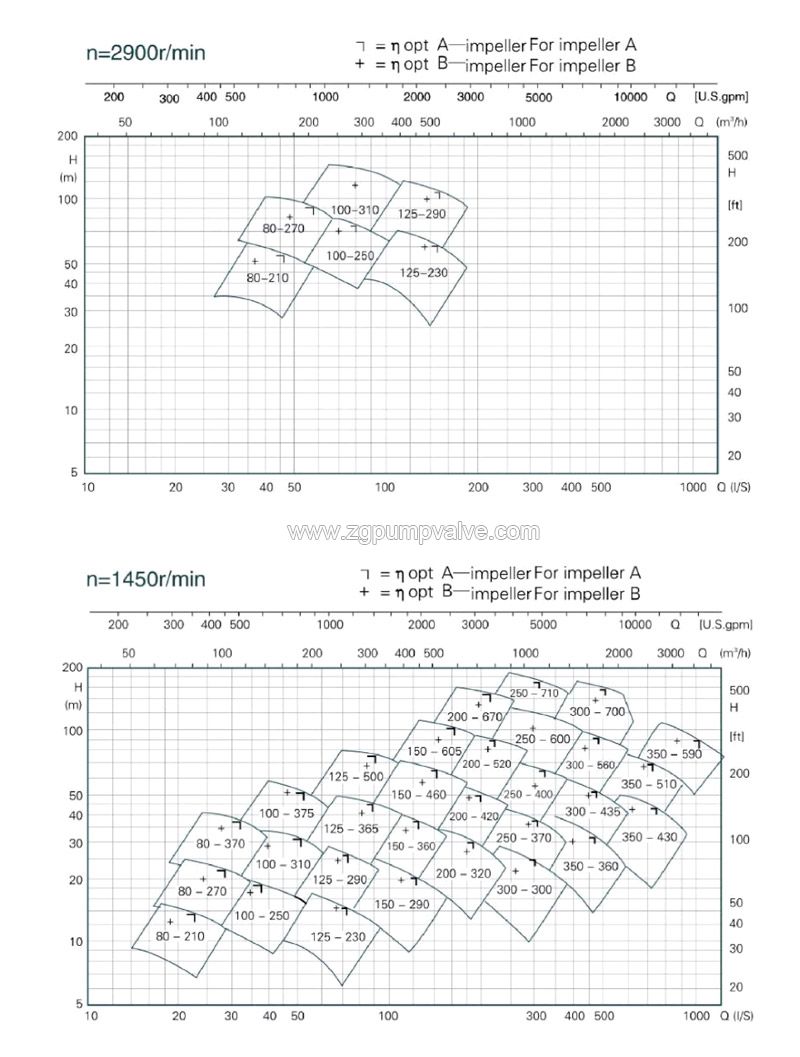

■Flow rate:Q=20~12000m3/h

■Total head:H=9~105m

■Speed:n=585rpm/2950rpm

■S.g.:γ ≤1.15

■Temperature:T=--10~105℃

■The installation of COS series pump can be horizontal and vertical, and for the horizontal one, the driver can be in the left and right according to the user’s requires.

■The flange hole can according to the GB, ISO, DIN, or ASI standard.

■The two sides of horizontal one can adopt the grease lubrication bearing and the dilute oil lubrication, the down side is SIC wear resistant sliding bearing.

■According to the user’s need, the pump rotating direction can be the clockwise or counterclockwise.

■Single stage,double suction,axial split casing centrifugal pump.Double passage casing to reduce the axial forces.

■Both pump inlet and outlet are beneath the pump centerline,the rotary part can be removed from the casing without dismantle the pipelines.

■Shortened shaft and enlarged diameter of shaft design to increase the life of bearings and mechanical seals.

■Completely sealed shaft design, zero contact with fluids.

■Various materials of shaft sleeve to prevent the shaft from abrasion and corrosion.

■Both mechanical seal and packing seal are available;mechanical seal can be changed without dismantle the pump cover.

■Different rotation directions are available.

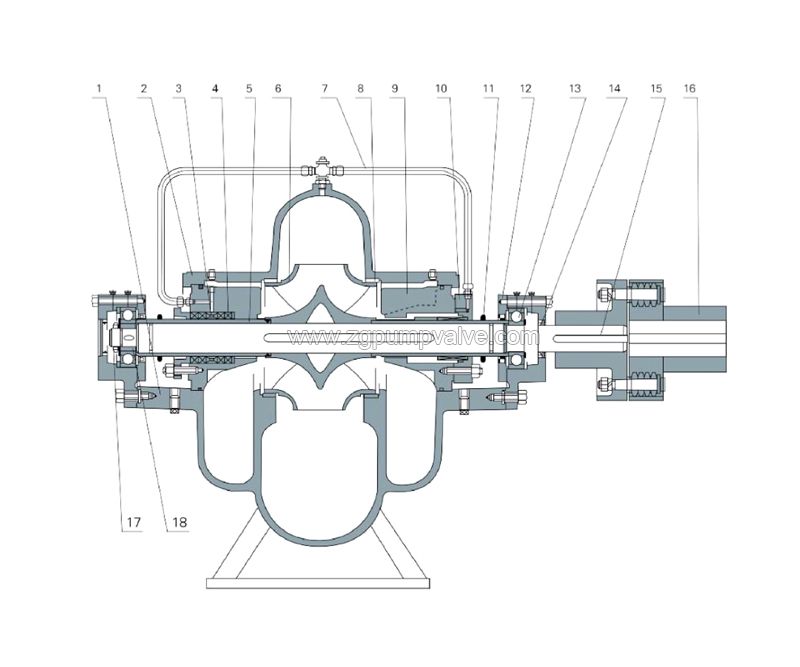

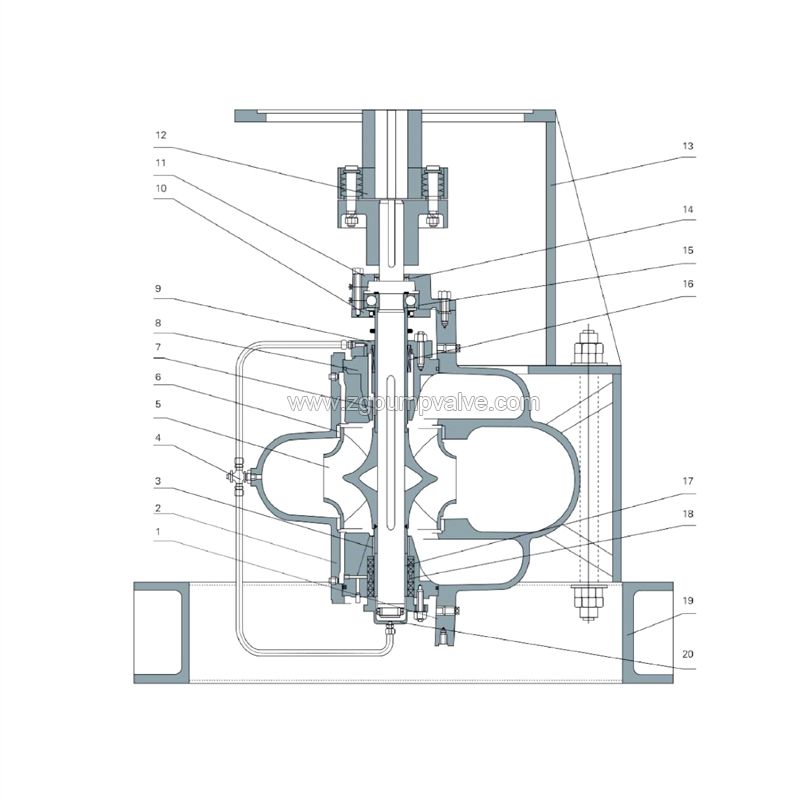

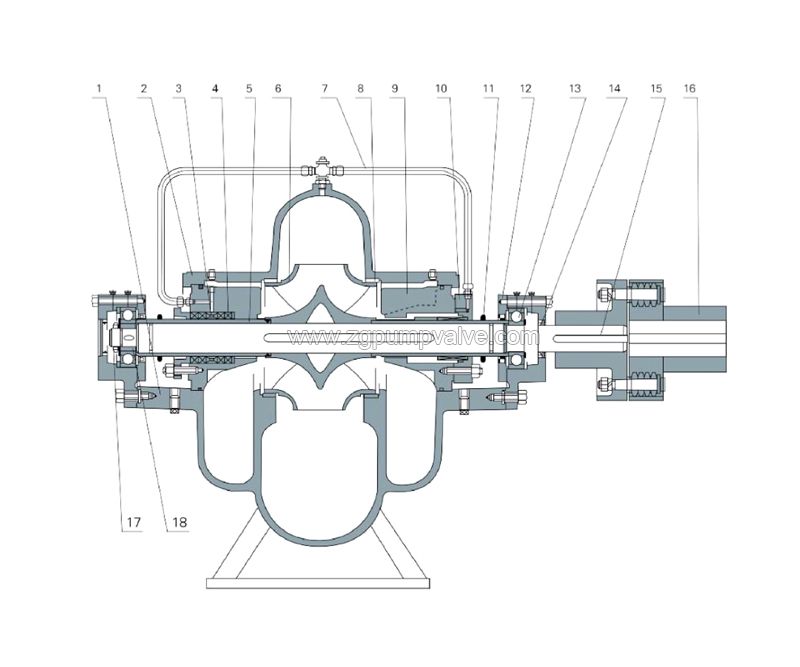

Structure drawing is as below:

1. Construction section of type COS pump

1. Pump casing 2. Impeller 3. Pump cover 4. Flushing water piping 5. Seal ring 6. Pipe plug | 7. O ring 8. Seal housing 9. Packing gland 10. Block water ring 11. Bearing gland 12. Bearing housing | 13. Shaft 14. Skeleton oil seal 15. Circlip 16. Bearing block ring 17. Bearing 18. Shaft sleeve |

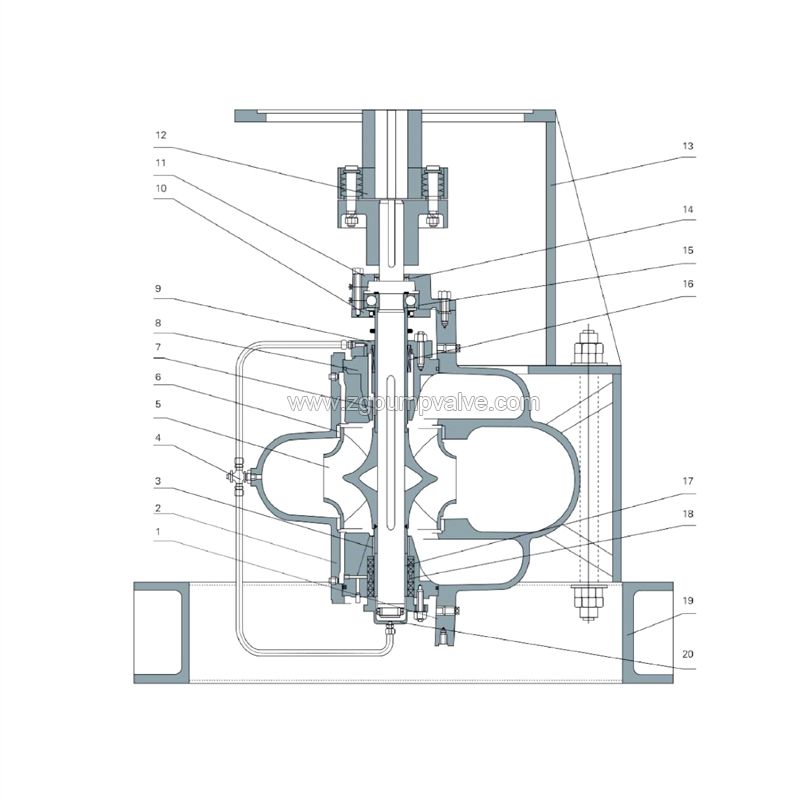

2. Construction section of type COS (L) pump

1. Pump casing 2. Pump cover 3. Sleeve 4. Shaft 5. Impeller 6. Seal ring 7. Shaft sleeve | 8. Vent plug 9. Seal housing 10. Flushing water piping 11. Packing gland 12. Bearing cover 13. Bearing housing 14. Bearing block | 15. Bearing block ring 16. Circlip 17. Skeleton oil seal 18. Bearing 19. Motor stool 20. Mechanical seal or packing |

| No. | Description | Material |

| Anti-corrosion alloy | Cast steel | Stainless steel |

China standard | ASTM standard | China standard | ASTM standard | China standard | ASTM standard |

| 1 | Pump casing | 20# Alloy Titanium Nickel 904L Ti/Pd Alloy Monel

| Hastelloy Monel Ⅱ-B Ⅱ-C Ni-Resist1 Ni-Resist2 Ni-Resist3 | 25# 35# | WCA WCB | ZG1Cr13 ZG2Cr13 ZG00Cr18Ni10 ZG0Cr18Ni9 ZG0Cr18Ni12Mo2Ti ZG0Cr17Ni4CuNb ZG1Cr18Ni9 ZG1Cr18Ni9Ti ZG00Cr17Ni14Mo2 0Cr26Ni5Mo2 0Cr17Mn13Mo2N 00Cr18Ni5Mo3Si2 | CA-15 CA-15M CF-3(SS304L) CF-8(SS304) CF-8M(SS316) CF-3M(SS316L) CN-7M(SS320) CD-4MCu 2205

|

| 2 | Sealing ring |

| 3 | Impeller |

| 4 | Pump cover |

| 5 | Impeller nut |

| 6 | Cartridge seal |

| 7 | Shaft | Carbon steel SS420 2205 SS304 SS316 |

| 8 | Bearing Housing | Cast iron |

| Item | Factory standard | Optional configurations |

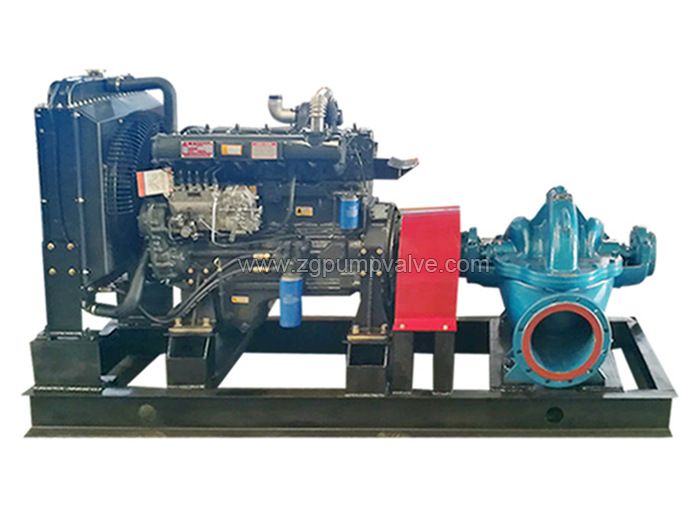

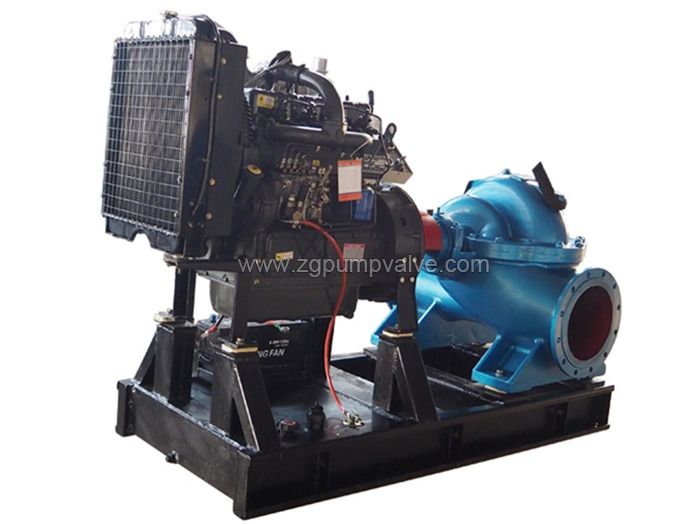

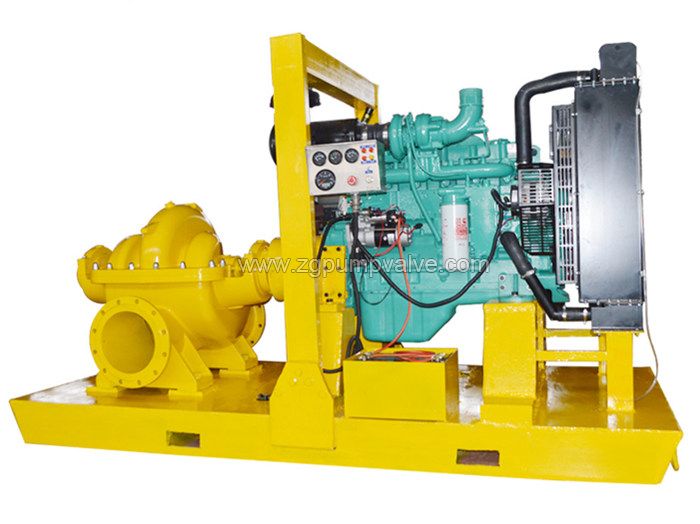

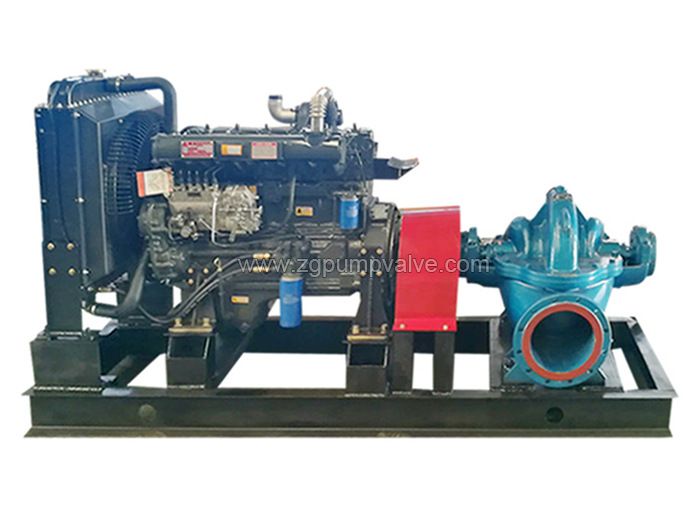

| Diesel Engine |  | Reputed China brands | Cummins, Deutz, or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Mechanical seal |  | Zigong brand | Burgmann, Sihuan riji, Chengdu Yitong |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

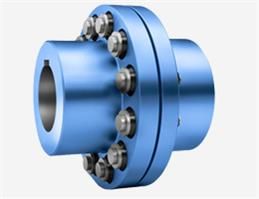

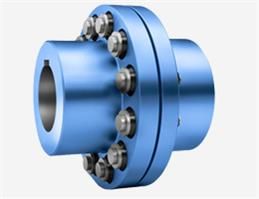

| Couplings |  | Pin type | Flexible diaphragm coupling |

■Fire fighting system,fire standby main pump

■Industrial process, For industrial emergency use, such as boiler water supply, high temperature water supply, etc

■municipal drainage,Urban flood control and drainage

■Used for agricultural irrigation in areas without power supply