■Flow rate: Q=0.6~100(m³/h)

■Total head: H=2~50 (m)

■Speed: n=2900rpm

■S.g.: γ ≤1

■Temperature: T=--20~180℃

■ The pump inner lining, the inner rotor of the impeller, and the isolation sleeve are all molded by pure F46 material, and no impurities are precipitated.

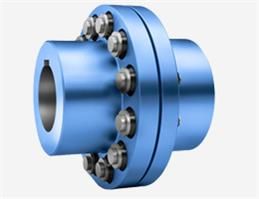

■ The shaft seal design of the traditional centrifugal pump was cancelled. Indirect drive with magnetic coupling to achieve zero leakage. It is very suitable for special occasions such as medicine, chemical, aviation, and standard workshops.

■ Fluorine-lined pump casing adopts high temperature annealing technology. The fluorine layer of the pump body is tightly fitted, and the fluorine is smooth and the strength is high. Very suitable for use in strong acid and alkali conditions.

■ Magnetic steel uses special materials, never demagnetizes, can smoothly transfer the torque of the prime mover to the impeller, and will not slip under large flow conditions, and can prevent the inner rotor of the impeller from contacting the rear thrust ring, thus preventing Melting fluoroplastic parts due to frictional heat, ensuring that the magnetic pump can operate normally in highly corrosive conditions;

■ The isolation sleeve is made of imported carbon fiber. It has ultra-high overpressure performance, which makes the pump set can withstand higher system pressure and can eliminate the heat generated by the metal sleeve due to magnetic eddy current;

■ Impeller rotor has the characteristics of high strength, non-deformation, corrosion resistance, smooth flow path, superior water conservancy performance, small hydraulic friction loss and high efficiency.

■The impeller is integrally molded by PTFE, and the PTFE is wrapped with steel inside.

■The wear ring is made of PTFE or SiC

■Pump casing made of cast iron and lined with ETFE/PTFE/FEP/PVDF/PP;

■Base is cast iron

■Plain bearings, PTFE filled SIN, SIC, SSIC, etc.

■CQB-F type fluoroplastic/PTFE lining magnetic drive pump is widely used in Chlor-alkali, Chlorobenzene, Chemical Foil, Pickling, Pesticide, Pharmaceutical, etc.