Learn - Mar. 23, 2023

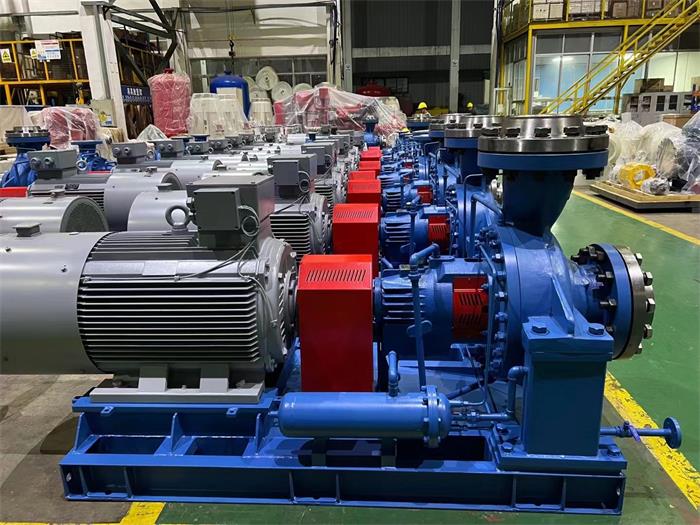

High temperature hot water circulating pumps are important fluid equipment for conveying high temperature medium in metallurgy, petrochemical, chemical and electric power industries. The hot water circulating pump is a horizontal centrifugal pump with single stage and end suction cantilever. The support type is horizontal center line support. The deformation and displacement of the pump caused by thermal expansion and cold contraction at high temperature are minimal.

A hot water circulating pump is the core equipment of closed circulating cooling system of blast furnace, and it is one of the very key production equipment in metallurgical industry.

The operation condition of the hot water circulating pump is high temperature and high pressure. The safe and stable operation of the hot water circulating pump is related to the smooth progress of the whole metallurgical process.

The Metallurgical hot water circulating pump adopts closed impeller, the back cover has a balance hole, the pump body adopts the double volute structure, the support type is centerline mounted OH2 support, and the bearing box has a cooling system. Water cooling chambers are designed in the support of a high temperature hot water circulating pump. They prevent high temperature heat conduction through the pump baseplate to the motor, thus affecting the normal operation of the motor. The hot water pump is dealing with high temperature medium, at high pressure, it requires high reliability and safety of pump operation.

We introduce a metallurgical high-temperature hot water circulating pump from three aspects: 1. Pump structure; 2. Pump seal and cooling system; 3. Pump material.

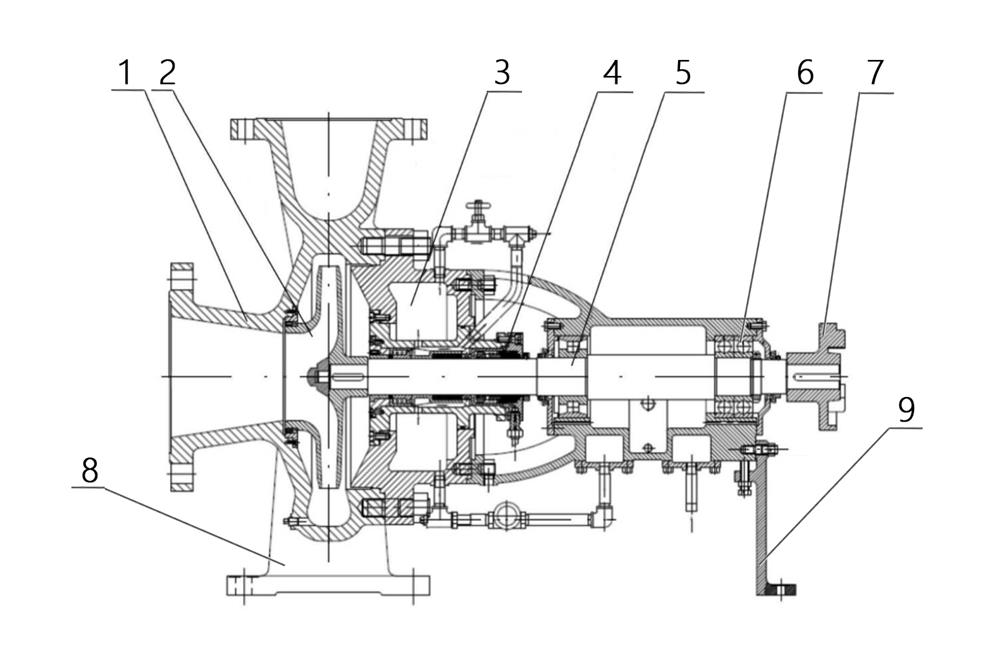

The structure of a high temperature hot water circulating pump is single stage end suction cantilever centrifugal volute pump. It is consisted of : pump body, pump cover, impeller, shaft, bearing box, sealing and flushing cooling system, flexible diaphragm coupling, pump support and pump baseplate, etc. Pump body adopts radial split, axial horizontal suction, vertical discharge. The support type is horizontal centerline mounted support, which can avoid obvious deformation and displacement caused by thermal expansion and cold contraction at high temperature.

The working condition of a high temperature hot water circulating pumps is high temperature and high pressure, should balance the force of the pump. The water discharge of this pump is designed into double volute chambers, and the double volute chambers are arranged symmetrical 180°, so that the radial force of the pump is balanced. The impeller design balances the axial force of the pump through the pressure difference generated by the balance hole and the diameter difference of the front and back sealing rings of the impeller. The operating parameters of the high-temperature hot water circulation pump in metallurgical industry is: medium temperature 250℃, working pressure 4MPa, and the design parameters is: pump pressure 6.4MPa, temperature resistance 280℃.

High temperature hot water pumps usually adopt balanced static mechanical seals. The end face of the friction pair of the mechanical seal has a hot fluid dynamic pressure groove, which can better cool and lubricate the end face of the seal. The liquid in the sealing chamber flows through the cooler to cool, and then returns to the mechanical sealing chamber to rinse and cool the mechanical seal end face, forming a closed self-circulating system. In this way, the limited liquid in the sealing chamber realizes its own circulation cooling, reduces the temperature in the sealing chamber, and ensures that the mechanical seal could operate reliably for a long time. This closed self-circulating mechanical seal cooling system extends the lifetime of the mechanical seal and the maintenance period of the high temperature hot water circulating pump.

Metallurgical high temperature hot water pumps handle high temperature and high pressure medium. In order to make sure the normal operation of the high temperature hot water circulation pump for a long time, the shaft seal cavity, bearing box and pump support should be cooled with external cooling water flush. The layout of cooling water pipelines conforms to the API610 standards.

A ring water cooling jacket is installed on the bearing box to play the role of heat insulation and cooling. A water cooling chamber is arranged at the lower part of the lubricating oil chamber to cool the lubricating oil and ensure the lubricity of the bearing under high temperature conditions.

For a general metallurgical high temperature hot water pump, The materials of pump body and pump cover are 1Cr13, impeller and shaft are 2Cr13, rings are 3Cr13, brackets are ZG230-450. According to the specific working condition, sometimes, the impeller is made of ZG12Cr13 stainless steel, the pump shaft and bolt are made of 35CrMo, it much more high temperature resistance .

| Material | t/℃ | ρ/ (g ·cm-3) | E/GPa | α/ (10-6K-1) | K/ (W ·m-1 ·K-1) |

| 1Cr13 | 190 220 250 | 7.75 | 205.42 203.23 201.04 | 10.95 11.10 11.25 | 25.943 26.234 26.525 |

2Cr13 | 190 220 250 | 7.75 | 207.73 205.24 202.75 | 10.95 11.10 11.25 | 23.278 36.614 23.950 |

| 3Cr13 | 190 220 250 | 7.76 | 209.20 207.36 205.53 | 10.95 11.10 11.05 | 25.460 25.500 |

| ZG230-450 | Amb. | 7.80 | 197.00 | 12.80 | 51.100 |

We are reliable and responsible partnerships with Metallurgical industry. Our customers always benefit from our experience, expertise, wide pump series and comprehensive service.

Optimized pump structure、Effective sealing and cooling system and material experts make sure reliable and safe operation of high temperature hot water circulation pumps in metallurgical industry.