Learn - Sep. 26, 2022

Pump wear occurs in three aspects

The so-called wear is the machine working surface in the process of relative movement, due to the mechanical or other effects caused by foreign bodies, so that the surface material loss, finally leading to mechanical failure phenomenon.

From the perspective of wear, wear can be roughly divided into① impact wear (or erosion wear), ② cavitation wear and ③corrosion wear. Erosion wear means that the solid particles carried in the liquid impinges on the flow parts at a certain speed, resulting in the loss of surface materials. It's a change in momentum and impulse, and the damage is serious. Chemical pump selection, pump material selection, very important, chemical pump need to meet the requirements of wear resistance.Our company has experienced sales, communicating with technical engineers and end users, can choose the most appropriate pump model, size, material, matching motor, and so on.

Cavitation wear refers to the operation of the pump in the process, the local area of the flow parts (usually the impeller inlet later position) for some reason, the absolute pressure of the pumping liquid drops to the gasification pressure at that temperature, the liquid will start gasification, steam, forming bubbles. These bubbles flow with the liquid, and when they reach a high pressure, the bubbles are compressed so rapidly that they burst. At the same time of the bubble bursting, the liquid particles fill the pores at a high speed and produce a strong impact on the metal surface. The metal surface is subjected to the impact of fatigue and peeling, resulting in the loss of surface material, serious metal surface is honeycomb. Usually cavitation occurs in the impeller outlet and volute inlet.

Corrosion wear refers to the conveying medium has a certain pH, corrosion and wear under the joint action of the material loss phenomenon. Corrosion can be divided into chemical corrosion and electrochemical corrosion. Chemical corrosion is the direct reaction between metal and liquid medium and the loss of metal; Point chemical corrosion is the formation of microcells on the metal surface under the action of liquid medium and the loss of material. Since the metal materials we use are all polyphase and polycrystalline materials, electrochemical corrosion mainly occurs.

Theoretical analysis of wear of desulphurization pump (mixed flow pump)

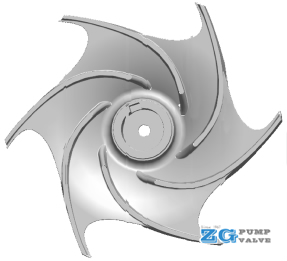

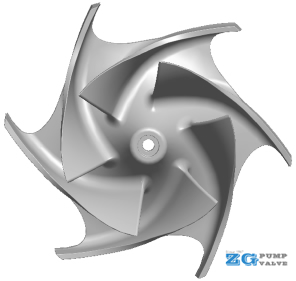

In the transport of solid-liquid two-phase flow in desulfurization pump, the density of CaCO3 solid particles is greater than that of liquid water. When conveying solid-liquid two-phase fluid, the head of the mixed flow pump is lower than that when conveying water, and the flow rate is higher than that when conveying water. Density or larger diameter of particles, their own quality, to produce centrifugal force in the impeller passage is big, the effect of centrifugal force makes the impeller in the movement of the solid particles from impeller blade working face, the curvature of the solid in the impeller motion is small, that is dense or larger diameter of particles in the impeller time is shorter, they collide impeller less chance of working face. On the contrary, the movement curvature of particles with small density or small diameter in the impeller is larger, which causes wear on the impeller blade working face, especially in the impeller blade outlet area. The main wear parts of the impeller in the impeller inlet and outlet, blade working face, blade front streamline and front cover plate.

After the solid particles leave the impeller, although they are no longer directly affected by the rotating motion of the impeller, but the particles still continue to move in the pump shell under the action of inertia force and liquid. The large solid particles leave the impeller with a large exit Angle, and impact the volute perimeter wall with a large radial velocity, and finally flow along the perimeter wall to the pump shell outlet. The larger the diameter of solid particles, the greater the density, the more tightly the volute wall, and between the pump shell wall and the outer edge of the impeller particle diameter gradually becomes smaller, the concentration gradually tends to be uniform. Small solid particles flow into the pump shell at a small outlet Angle, and their trajectories are approximately concentric circles. The distribution of small solid particles in the pump shell is relatively uniform, and the wear of the side and surrounding walls of the pump shell is also relatively uniform.

It can be seen that the larger solid particles make the pump shell wall wear more serious, so the slurry pump shell wall should be thickened when transporting large particles of solid. The large tongue gap is generally used in the design of two-phase flow pump. The large tongue gap can reduce the kinetic energy of the solid, so as to reduce the wear of the pump shell wall. The large tongue gap is also conducive to large particles of solid through the tongue and out of the pump body, but the large tongue gap will change the movement direction of the mixed liquid, the flow direction of solid particles offset, the solid particles are easy to collide with the tongue, so that the wear of tongue is more serious.

Effective measures to prevent wear of desulphurization pump (mixed flow pump)

(1) Surface coating; In the impeller, volute flow surface and impeller surface easy to wear parts coated with polymer wear-resistant material.

(2) Thermal spraying (welding): Plasma spraying or oxyacetylene flame is used to spray cerm or tungsten carbide or spray welding nickel-based + tungsten carbide alloy on the easily worn surface.

(3) Surface surfacing; Wear-resistant electrode and powder block are used to surfacing wear-resistant alloy in the easily worn part of desulfurization pump.

(4) Silicon carbide lining desulfurization pump, also known as ceramic desulfurization pump, adopting non-pressure sintered silicon carbide material, this ceramic desulfurization has the advantages of high strength, high hard, corrosion resistance, abrasion resistance, suitable for large flow, medium head of solid-liquid two-phase flow desulfurization process.