Learn - Jul. 08, 2020

First of all, we must understand the causes of chemical pump corrosion. For the classification of corrosion, there are generally two classification methods, one is based on the mechanism of corrosion, and the other is based on the cause and appearance of corrosion.

According to the mechanism of corrosion, it can be divided into electrochemical corrosion and chemical corrosion. Electrochemical corrosion mainly refers to the occurrence of corrosion due to the surface electrode reaction that occurs after the metal material comes into contact with the electrolyte solution. This reaction is generally a redox reaction, and the main factors are the humidity and temperature of the environment; Chemical corrosion refers to the strong chemical reaction between the metal surface and the surrounding medium, which will cause certain damage to the metal. The main reasons for this corrosion are high temperature and dry environment. According to the appearance and cause of the corrosion, it can be divided into stripping corrosion, industrial atmospheric corrosion, high-temperature oxidation corrosion, and marine atmospheric corrosion.

In those environments with serious industrial pollution, because there are more volatile substances such as sulfides, carbon dioxide, and hydroxides in the air, and also contain some industrial dust, these are media that are easy to cause corrosion. Under these humid environments, acid gas will combine with water to form inorganic acids. These acids have strong corrosive properties, so they will induce corrosion. In the environment of the industrial atmosphere, the equipment is caused by the combined effects of electrochemical corrosion and direct chemical corrosion. The essence of all corrosion is actually an oxidation process in which metal elements form ions after losing electrons. The main difference between electrochemical corrosion and industrial atmospheric corrosion is the environment in which the two occur.

solution:

The corrosion of equipment is closely related to the material of the equipment. During the selection of chemical materials, it is necessary to focus on the occurrence of corrosion, pay attention to the rational selection of materials, and fully consider the nature of the medium, the temperature of the environment, and the operating pressure. The requirements of raw materials design the structure and type of equipment.

The design of the structure should focus on the production requirements and stress characteristics of the production and operation of chemical equipment. In the design, it is necessary to pay attention to the following aspects:

The first is that the product's structural requirements for the product should be consistent with the corrosion resistance requirements for the production of chemical products;

Secondly, it is necessary to pay attention to the operating stability and fluency of chemical equipment, to prevent the pause of the medium with corrosive performance, the uneven distribution of heat load, and the condensation of steam and the accumulation of corrosion products; finally, we must pay attention to the protection of external forces to prevent Fatigue corrosion caused by alternating stress.

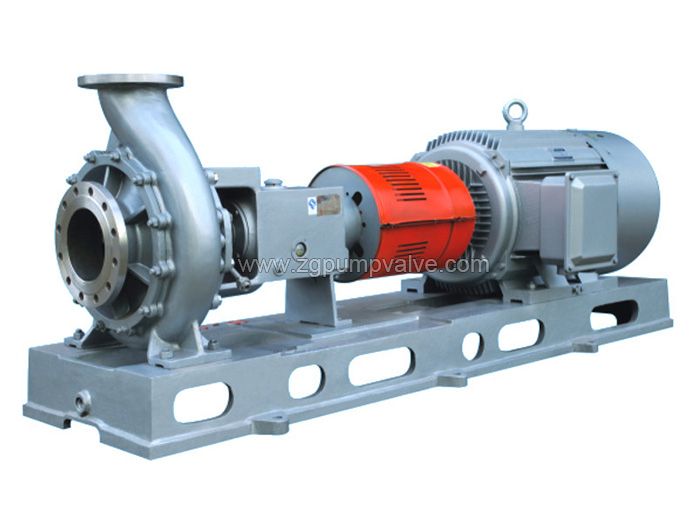

The above information is provided by a centrifugal pump factory.