Learn - Feb. 12, 2025

When selecting a centrifugal pump for fluids containing chlorides, we often recommend either a duplex stainless steel pump or a titanium pump. Of course, the choice depends on the temperature and density of the fluid as well as the purchase price. To solve the problem of choosing a duplex stainless steel centrifugal pump or a titanium pump for your specific application, we have listed the comparison between the two for purchasers. This guide would be of great help when buying these two types of pumps.

Duplex stainless steel centrifugal pumps are designed with wetted parts made of duplex stainless steel, offering outstanding corrosion resistance. These pumps excel in handling concentrated brine, brine, seawater, and other chloride-containing circumstances. Widely used in the chemical industry, they are a reliable choice for applications where durability and performance are paramount.

Duplex stainless steel combines the advantages of ferritic and austenitic stainless steels. It has excellent weldability, high strength and good resistance to chloride stress corrosion.

Advantages of duplex stainless steel:

● Excellent resistance to acid corrosion

● Strong resistance to pitting and crevice tunnel corrosion

● High yield strength and high plasticity and toughness

● Low coefficient of thermal expansion.

Duplex stainless steel boasts exceptional resistance to pitting corrosion and wear, making it an excellent choice for demanding applications.

The chemical composition of 2205 duplex stainless steel: Cr = 22%, Ni = 5%, Mo = 3%, N = 0.14 - 0.2%, C ≤ 0.03%, PREN 34 - 36. It is suitable for medium containing chloride ions and is often called duplex stainless steel seawater centrifugal pumps and duplex stainless steel chemical centrifugal pumps.

2507 duplex stainless steel is a third-generation super duplex stainless steel with an ultra-low carbon content (C ≤ 0.03%), PREMn > 40, high chromium (Cr ≥ 25%), Ni = 7%, high molybdenum (Mo ≥ 4%), and high nitrogen (N = 0.3%). It is mainly used in harsh medium, especially in chlorine-containing working conditions, and has excellent corrosion resistance. The super duplex stainless steel used for manufacturing pumps is 2507.

While duplex stainless steel offers many advantages, it's important to note that its resistance to chloride corrosion diminishes when temperatures exceed 250℃. For applications with higher temperatures and concentrations, a titanium centrifugal pump may be a more reliable and suitable option.

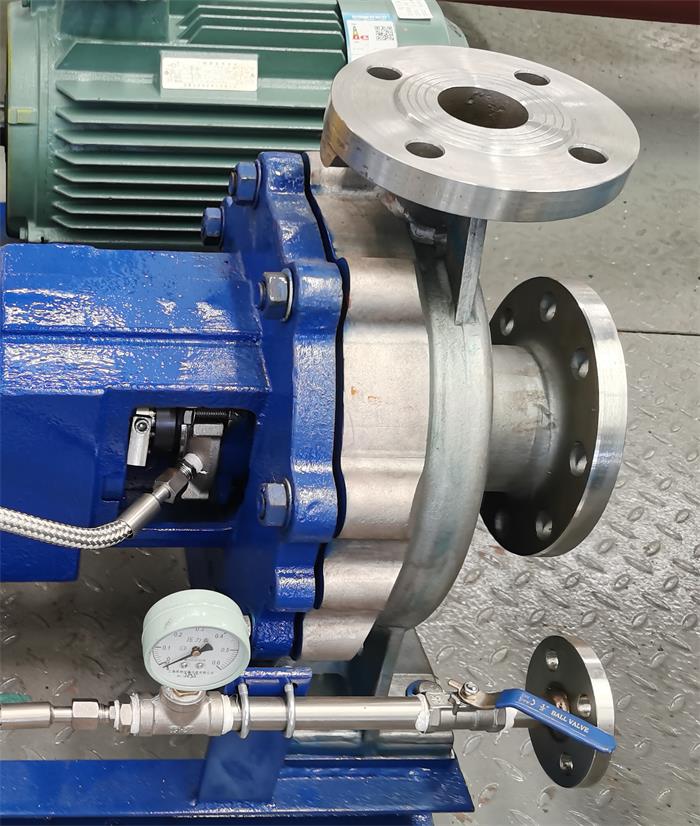

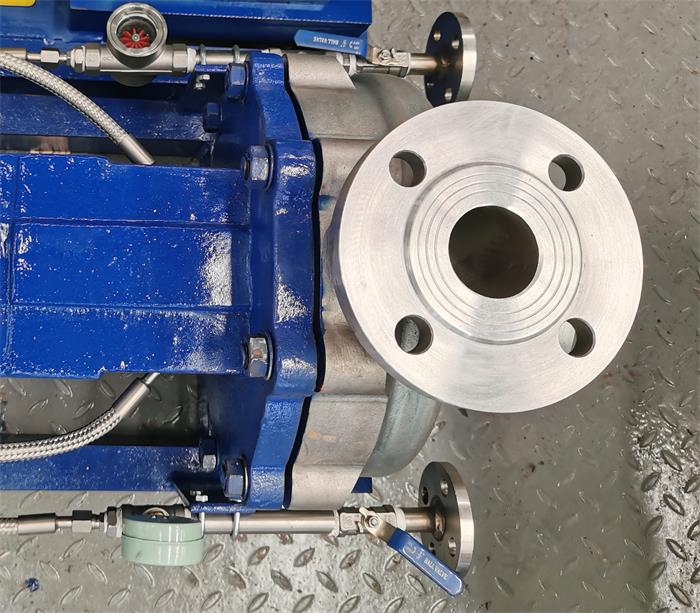

A titanium centrifugal pump is a kind of centrifugal pump which wetted parts (pump casing, impeller, pump gland and other accessories) are made from titanium or titanium alloy.

Titanium has a density of approximately 4.51 g/cm³ and a tensile strength Rm > 300 MPa. It is lightweight, high-strength, has a high yield-to-tensile ratio, is non-magnetic, biologically inert, and especially has excellent corrosion resistance. In recent years, due to the rapid increase in the production of titanium materials, the price is no longer as high as before, and the output of titanium centrifugal pumps is getting larger and larger.

Titanium centrifugal pumps have become an essential and reliable choice for fluid handling in the salt production industry, especially when it comes to transporting corrosive medium. These pumps excel in environments with higher temperatures and elevated chloride concentrations. Compared to duplex stainless steel centrifugal pumps, titanium pumps not only offer a longer service life but also can handle higher operating temperatures, ensuring dependable performance even under challenging conditions.

Titanium materials boast high strength and low density, meaning that titanium centrifugal pumps are not only robust and long-lasting but also lightweight, which makes installation and maintenance much easier. Moreover, titanium alloys offer outstanding mechanical processing capabilities, enabling the production of highly precise components. This ensures the pump operates efficiently and enjoys a longer service life.

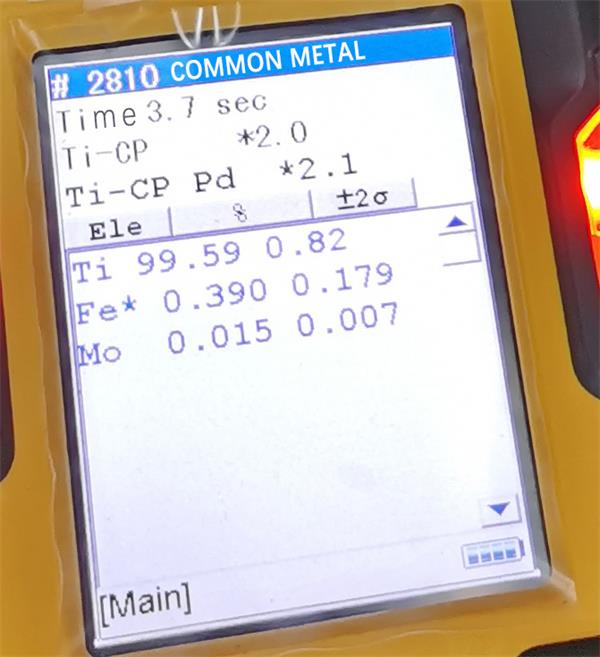

The characteristics of industrial pure titanium are: it cannot be strengthened by heat treatment, has excellent formability, and is easy to melt weld and braze. Pure titanium has extensive applications in the chemical industry. The grade TA2 of pure titanium is often used to manufacture centrifugal pumps.

The characteristics of titanium alloy are: good weldability, castability, pressure processing performance, organizational stability and no cold brittleness. Titanium alloy has extensive applications in the general industry and chemical industry. The grade TA9 and TA10 of titanium alloy are often used to manufacture centrifugal pumps.

Titanium materials have extremely wide applications in the chemical industry and are used for transporting highly corrosive medium such as chlor-alkali and salt production.

Due to the different performance requirements and forming processes of various components of titanium centrifugal pumps, the overall price of titanium centrifugal pumps sometimes does not correlate with the price of titanium raw materials. As a result, large titanium centrifugal pumps tend to be quite expensive.

Duplex stainless steel centrifugal pumps and titanium centrifugal pumps are very similar in many application scenarios and are widely used in salt production, chlor-alkali production, and seawater treatment, among other conditions. Although the initial purchase cost of titanium centrifugal pumps is higher, their service life is longer. Especially in high-temperature and high-salinity environments, titanium centrifugal pumps are indispensable choices.

The differences between duplex stainless steel centrifugal pumps and titanium centrifugal pumps are not only reflected in their prices, but also in their respective application characteristics and performance. Our sales team and engineers have rich professional experience in this field and are well aware of the importance of analyzing the details of the medium. Every detail reflects our professional spirit. We are committed to providing you with a comprehensive and meticulous fluid integrated solution to ensure that no key point is overlooked.