Learn - Nov. 27, 2020

When the user hears the process pump crackling, like the sound made by sand slowly flowing onto a tin roof, the user's utmost attention is required, as this sound indicates cavitation. Process pump supplier will explain cavitation issues.

A large percentage of process pump failures in the chemical industry are due to NPSH cavitation margins, the air in the conveyed media, dry friction after oil loss, or process pump drives that operate outside the allowable operating range. Faulty use and design are the main causes of process pump damage, accounting for 90% to 95% of all process pump damage. People do not know a pump is defective until there is a problem with the chemical pump.

According to Bernoulli's principle, the faster the speed of the flowing medium, the less static pressure it generates. When the static pressure is less than the evaporation pressure of the liquid, cavitation bubbles or air bubbles appear, which are re-concentrated and liquefied under the high pressure and temperature conditions in the high-pressure zone.

The effects and consequences of cavitation are highly dependent on the pump itself, but also on the nature of the fluid medium (temperature, vapor pressure) and the equipment conditions on the suction side. For some special cases, it is recommended to install a deflector wheel in front of the rotor impeller. The deflector works like a primary pump, which conveys the liquid medium to be conveyed to the process pump, increasing the pressure at the suction side of the vane pump (solving the cavitation margin problem). It can be mounted directly on the shaft of the process pump, before the rotor impeller.

The weakest link in the process pump is the suction port on the suction side of the process pump, where the bubbles formed are crushed by the suction flow, but eventually, coalesce again like a shock inside the process pump. The resulting liquid micro-jets hit the inner surface of the pump at very high speeds and pressures (up to 20 000 bar), with the following consequences.

(1) Damage to the components of the process pump (especially the rotor vanes) due to the pulsating impact of the vaporized vapor bubbles.

(2) Changes the operating characteristic curve of the pump, and thus the operating point of the pump (until it stops pumping completely).

3) Vibration and (solid) noise skyrocketed.

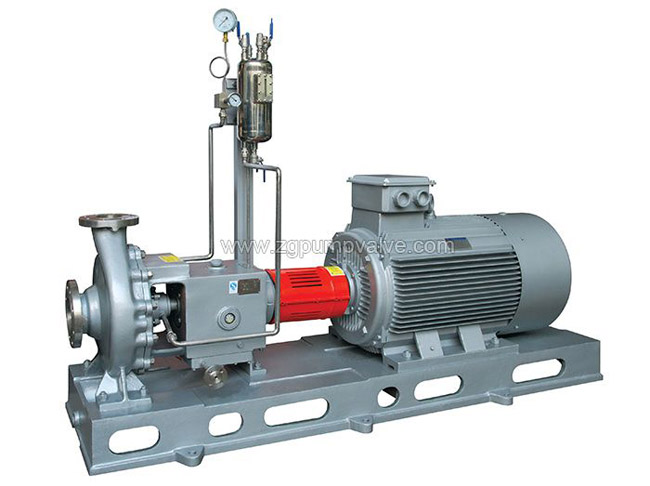

HZ chemical process pump is a single-stage, single-suction, cantilever centrifugal pump which absorbs advanced technology from abroad and is designed according to the advantages of F1, IH, CZ, ZBG chemical process pump. For more information about good quality process pumps, please contact us.