Learn - Aug. 01, 2023

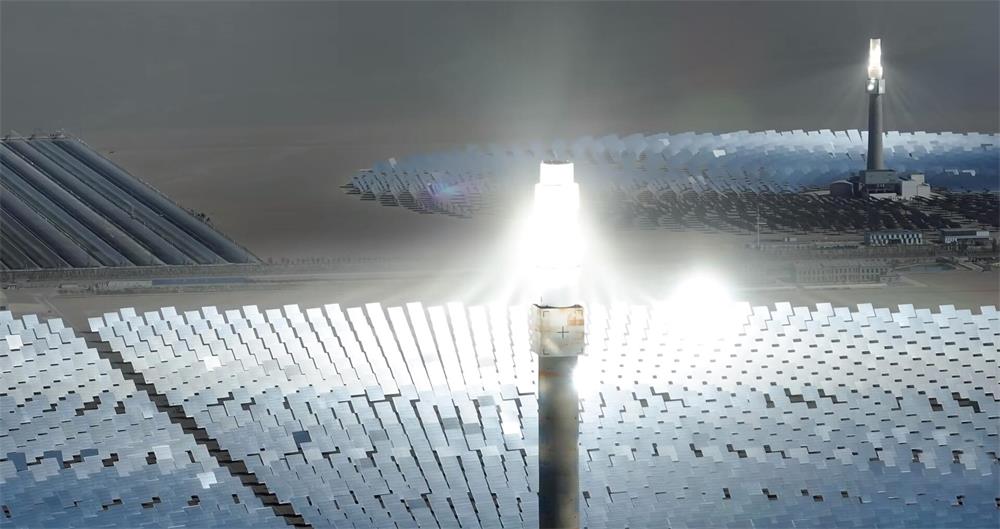

Nowadays the application fields of high temperature molten salt pumps are more and more wide. Molten salt pumps (MSP) are mainly used for conveying molten salt, high temperature nitrite, ionic membrane caustic soda, and are also widely used in chemical processes such as melamine, salt making, alkali tablets and phthalic anhydride. A molten salt pump is also one of the key equipment in the process of pipeline dissolution of alumina. Molten salt pumps, also known as high temperature vertical long shaft pumps, used to handle with high temperature molten salt and sort of that. Because molten salt has characteristic of heat storage, in recent years, it has been used as a heat transfer medium in Concentrating Solar Power solar Stations and nuclear reactors. The vertical high temperature molten salt pump provides power for forced circulation of molten salt.

Molten salt pumps have to withstand super high temperatures, how does it do this? What are the special points in the material and parts configuration of the molten salt pump?

First, the material selection of flow parts of molten salt pumps consider high temperature and corrosion resistance. The material of flow parts of molten salt pumps select : For the medium with a temperature of 230~400 ℃, the pump casing, support pipe and other materials could be selected carbon steel, martensitic stainless steel or stainless steel; Impeller could be selected stainless steel or duplex stainless steel; The outlet pipe could be selected carbon steel, hardened alloy or hardened steel. The shaft can be SS420 or 316SS. For the medium with a temperature of 400~565 ℃, The pump casing, support pipe, impeller and other flow parts could be selected cast steel, austenitic stainless steel, 347H or Hastelloy.

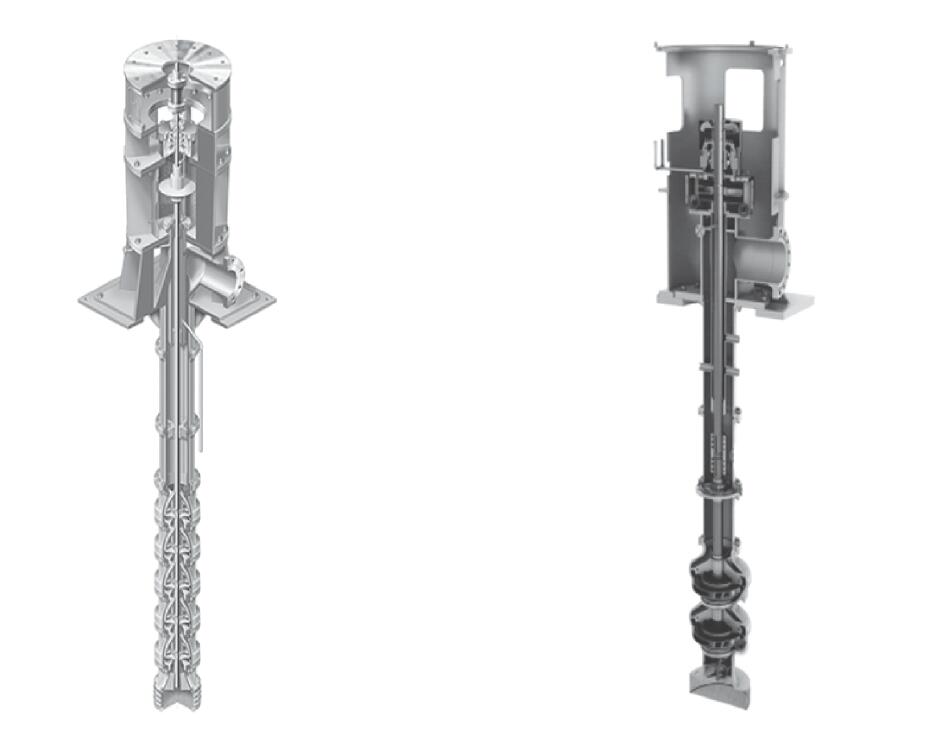

Some special configurations are used to resist high temperatures and excessive long shafts.

The high temperature molten salt pump used in molten salt reactor is a cantilever structure, and the long shaft is supported by sliding bearings. The submerged pump shaft of the molten salt pump is so long, from 8 meters to 25 meters, and the sliding bearing is used to increase the rigidity of the shaft and improve the critical speed of the shaft. The sliding bearings bear most of the radial forces of the molten salt pump during operation. Sliding bearings constrain the pump shaft to produce excessive deflection and radial circular runout to reduce pump vibration and mechanical losses. The sliding bearing has become the main factor affecting the maintenance cycle and service life of the molten salt pump, and plays a key role in the long-term reliable operation of the molten salt pump.

For longer shaft, not only be slider bearings are equipped on the upper part of the bottom plate, but also guide bearings should be added to provide radial support and stabilize the operation of the shafting. The guide bearing consists of a bushing mounted on the shaft and a bushing mounted on the housing. To withstand the temperature above 400 ° C , the guide bearing is made from austenitic stainless steel (347H) and cemented carbide surfacing.

Commonly the flow rate of Molten salt pumps is large, (except for some special small flow rate molten salt pump), the density of molten salt is large, the temperature is high, in order to balance the radial force generated when the pump is running, the radial guide vane is needed.

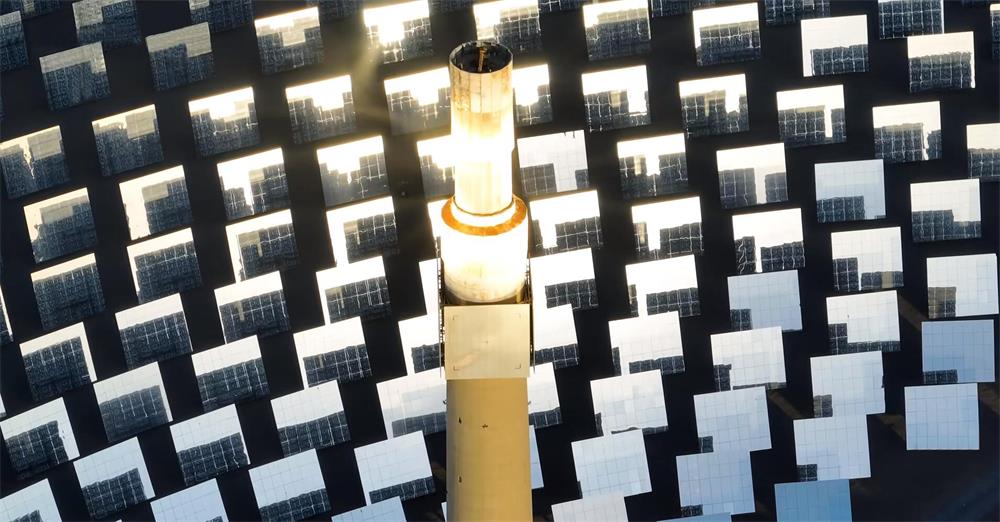

In the solar thermal power station, the molten salt pump operates at a high temperature of 270-550 ° C, and in the nuclear power plant, the temperature of the molten salt is even as high as 700-750 ° C, and the high temperature would affect the base and supporting steel frame of the molten salt pump. The base of the high-temperature molten salt pump is supported by a I-steel supporting frame, and the vibration generated by the molten salt pump during operation will be transmitted to the steel frame. Therefore, it is necessary to ensure the stability of the supporting steel frame. The high temperature area of the molten salt pump is mainly concentrated in the salt delivery pipe and the adjacent shaft tube. When the molten salt pump is in a stable working state, the temperature is constant at about 550℃, and the temperature of the salt delivery pipe wall is close to 550℃. By adding heat insulation gaskets, the steel frame temperature can always be maintained below 200℃ even when the molten salt temperature exceeds 550 ℃.

We manufacture molten salt pumps in a wide range of sizes and specifications, which are widely used in many industries:

In the chemical industry, molten salt pumps are used in processes that require precise temperature control, and molten salt is used as a heat medium for indirect heating, which is more reliable, safer and more convenient to operate than other direct heating or steam heating measures. Nitrate is widely used in chemical plant because of its advantages of low corrosiveness and low raw material cost. Such as melamine, phthalic anhydride, alumina, cable vulcanization, alkali tablets and other devices are used. The molten salt pump in the chemical device, according to the different working condition parameter requirements, the performance parameters is vary greatly, the working temperature is generally not more than 480 ° C, most of them are VS4, VS5 pump types.

Application of molten salt pumps in heat treatment of materials in mechanical industry Molten salt is used as a medium for heat treatment of materials. For example, the chloride mixture molten salt is used for annealing and isothermal quenching of steel, and the mixture of cyanide and chlorine salt is used for surface carburizing and carbonitriding of metal materials. The salt bath furnace is an industrial furnace that uses molten salt liquid as the heating medium to immerse the workpiece in the salt liquid for heating. Almost all the molten salt pumps used in salt bath furnaces belong to small flow rate molten salt pumps. The submerged depth of the molten salt pump is about 2 meters in such conditions, the flow rate is about ten or dozens of square, and the head is not high, usually select the double-volute double-outlet cantilever VS5 molten salt pump.

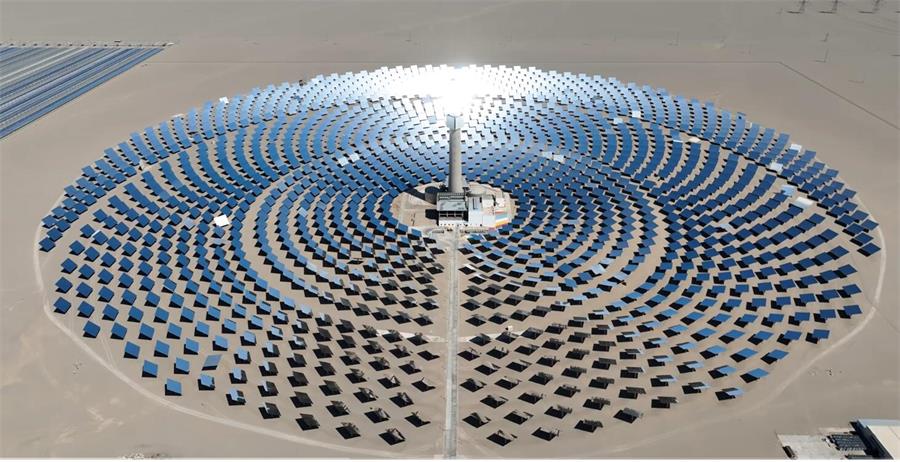

In concentrated solar thermal power stations, some of them use dual-tank heat storage systems, equipped with molten salt circulation pumps, vertical mixed flow pumps and attemperation pumps. In the Hami 50MW photothermal power generation projecct, there are three high temperature molten salt pumps, three cold salt circulation pumps and two attemperation pumps. In the Wulat Zhongqi 100MW trough concentrated solar thermal power generation project, there are six high temperature molten salt pumps and six cold salt pumps.