Learn - Jan. 23, 2025

In regions where freshwater resources are limited, such as coastal areas in arid climates and ships on long voyages, seawater desalination has become an increasingly important solution. Our reciprocating triplex plunger pumps have been successfully applied in numerous desalination plants worldwide, contributing significantly to the production of clean water. We offer reliable and efficient solutions and high-quality pumps to ensure a stable supply of fresh water.

Our products are widely applied in seawater desalination projects. For small-scale reverse osmosis seawater desalination units, reciprocating triplex plunger pumps are chosen. For medium and large-scale reverse osmosis seawater desalination projects, high-pressure centrifugal pumps are selected.

In seawater desalination projects using distillation methods—whether vapor compression(VC), multi-stage flash distillation(MSF), or low-temperature multi-effect distillation(LT-MED)—our large-diameter horizontal axial flow pumps are essential equipment.

Reverse osmosis seawater desalination technology is an important way to solve the shortage of fresh water resources on ships. The reverse osmosis seawater desalination equipment for ships has the advantages of miniaturization, integration and energy conservation, which meets the requirements of the limited space on ships.

The basic principle of reverse osmosis is: to avoid natural osmosis by applying external pressure and achieve reverse osmosis. By applying external pressure on the concentrated solution side and making it exceed the osmotic pressure, the dilute solution will flow from the osmotic membrane to the other side.

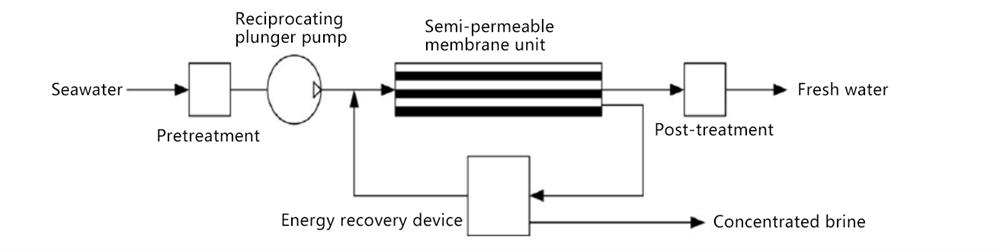

The process of reverse osmosis (the abbreviations used in the following text are: RO) seawater desalination is as follows: Seawater first undergoes pretreatment, where impurities are filtered out before entering a triplex plunger pump to increase the pressure of the seawater. When the seawater pressure rises to the osmotic pressure, fresh water in the seawater will pass through the reverse osmosis membrane and flow into the fresh water side, while salts and other components in the seawater are blocked on the seawater side.

This reciprocating triplex plunger pump is applied in the RO seawater desalination process, functioning as a three-in-one circulation pump that integrates a high-pressure pump, a pressure boosting pump and an energy recovery device.

Reciprocating triplex plunger pumps efficiently use the residual pressure from high-pressure concentrated seawater. By introducing this seawater into the rod chamber, the pump leverages its mechanical energy to drive the piston, reducing motor output power. This lowers the high-pressure pump motor power in RO desalination systems by over 60% and reduces fresh water production energy consumption by over 40%.

Reciprocating plunger pumps serve as the critical power components in RO seawater desalination systems, and their performance significantly influences the operational energy consumption of these systems. Key advantages of reciprocating plunger pumps include high volumetric efficiency, minimal leakage, stable operation under high pressure, and exceptional reliability.

The working principle of the Reciprocating plunger pump:

The reciprocating plunger pump is a type of positive displacement pump. Its working principle is to convert mechanical energy into pressure energy by changing the volume of the working chamber. This is mainly achieved through the reciprocating motion of the plunger in the working chamber. The reciprocating plunger pump is powered by a motor, which drives the crankshaft to rotate through a transmission belt, thereby pushing the three plungers to reciprocate in three sets of hydraulic cylinders in sequence.

Reciprocating plunger pumps can simultaneously achieve multiple functions such as high pressure, pressure increase and energy recovery.

The composition of reciprocating plunger pumps:

1. Cylinder block (pump body)

The reciprocating plunger pump used in the RO seawater desalination process adopts a structure with three hydraulic cylinders arranged side by side. The cylinder body is an integrated design, and the external contour presents a rectangular shape.

The wall thickness of the cylinder body: The cylinder body bears the main pressure of the reciprocating plunger pump. The shape of the cylinder body for energy recovery reciprocating plunger pumps is complex, and the wall thickness varies at different locations. The internal flow channels of the cylinder body are also complex, and the pressure endured at different locations is not uniform. For equipment used in seawater desalination projects, corrosion resistance must be taken into account. The cylinder barrel is in direct contact with the conveyed medium and requires materials with high strength and corrosion resistance. For reciprocating triplex plunger pumps applied in RO seawater desalination projects, duplex stainless steel, titanium or titanium alloy materials can be selected.

Titanium has stable physical and chemical properties and can form a protective film on its surface by itself, which makes it highly resistant to corrosion in seawater. Titanium plunger pumpshave extremely superior corrosion resistance and can operate stably for up to ten years.

2. Check valve

Spring-loaded flat plate valves are selected as the check valves for the reciprocating plunger pump used in the energy recovery process of RO seawater desalination.

3. Piston

The piston is a key component for pressure exchange in reciprocating plunger pumps and is one of the moving parts of the plunger pump. The piston and the cylinder form a dynamic seal. To minimize the mixture of medium, reliable sealing performance is required here. However, under the premise of ensuring sealing, friction and wear should be reduced to minimize power loss and extend service life.

4. Piston rod

The piston rod is a connecting component that supports the piston in doing work and transmits power to the piston.

There are various connection methods for pistons and piston rods, such as flange connection, threaded connection, and welding connection, etc. The reciprocating plunger pump applied in the RO seawater desalination process adopts a double-acting cylinder. During the reciprocating motion of the piston, the piston rod is subjected to both pressure and tension. The connection method of locknut plus gasket is the best connection method.

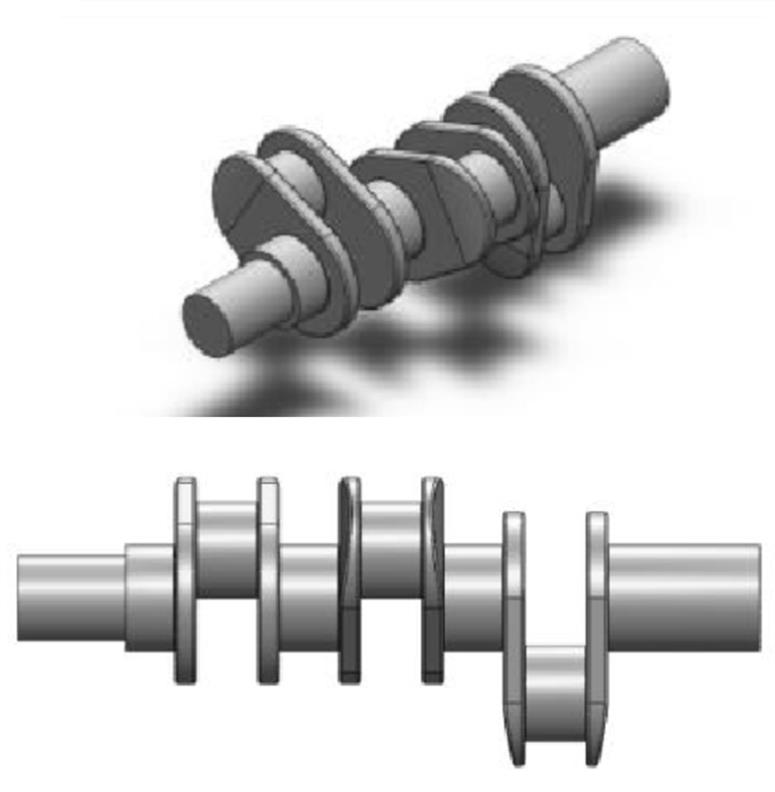

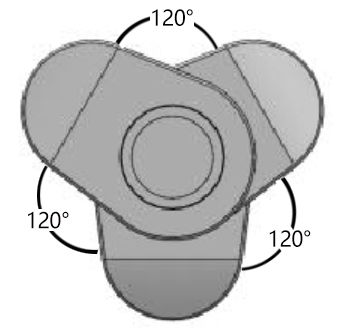

5. Crankshaft

The crankshaft is the transmission end that converts the original rotary motion of the motor into the reciprocating motion of the piston. The crankshaft must have good strength and rigidity. A two-bearing three-crankpin crankshaft is a good choice. A two-bearing three-crankpin crankshaft can not only provide the maximum pressure for the piston but also ensure the normal operation of the remaining parts of the crankshaft and connecting rod.

The crankshaft is a major component of the drive end of reciprocating plunger pumps, and the crank angles are staggered by 120° from each other.

The material for forging crankshafts is selected from high-quality 45# carbon steel. 45# carbon steel has excellent mechanical properties.

Density: 7.89×10³ kg/m³ Elastic modulus: 2.09×10¹¹ Pa Poisson's ratio: 0.269

6. Balance valve

7. Pressure relief valve

The advantages of reciprocating triplex plunger pumps, such as good sealing performance, high volumetric efficiency, and high matching accuracy, as well as their high reliability and stability under high-pressure conditions, determine that they can operate continuously and stably in RO seawater desalination devices.

End Suction Pump vs. Inline Pump: What Are The Differences?

Zigong Pump & Valve 2021 Marketing Work Conference was Held Successfully

How to extend the service life of chemical pumps - Maintenance of chemical pump properly

Application of High-temperature Hot Water Circulation Pumps in Metallurgical Industry

Application-Coal fired power generation -Desulfurization pump-Eco friendly