Learn - Mar. 02, 2023

The limestone-gypsum wet flue gas desulfurization technology is the most commonly used desulfurization technology in coal burning thermal power plants.

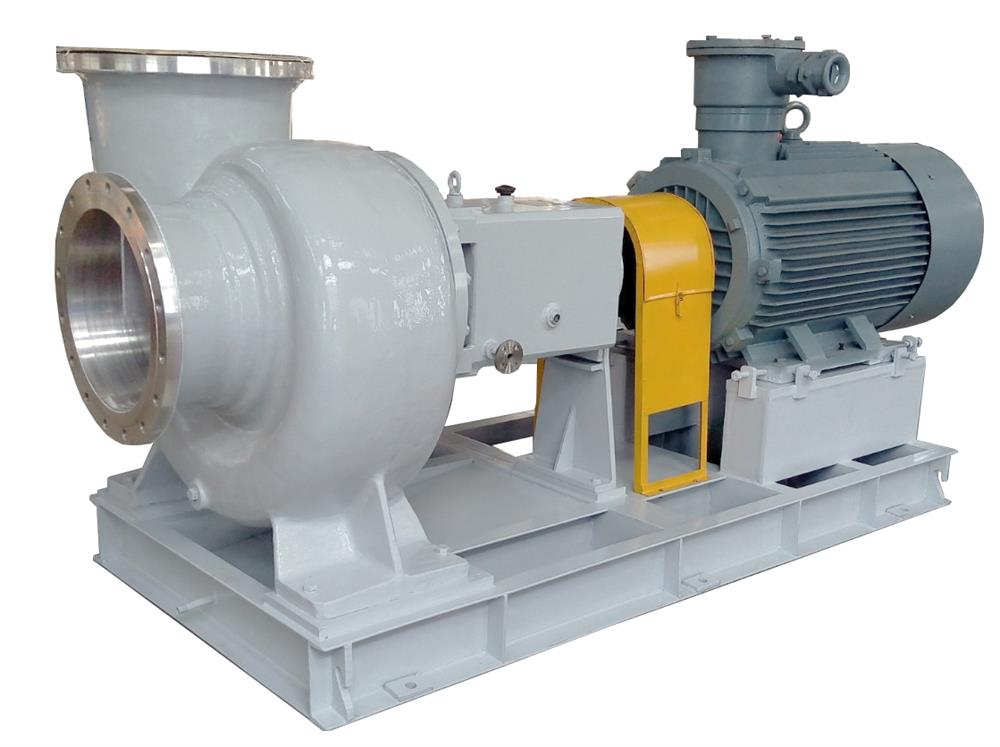

Desulphurization pumps as slurry circulating pumps are the key equipment in flue gas desulphurization unit.

The slurry in FGD process has both chloride corrosion and solid particle abrasion. This kind of solid-liquid two-phase medium has a high requirement for corrosion resistance and wear resistance of a mixed flow pump.

The material used in the flow parts of desulfurization pumps can be divided into three types: the all-metal pump, the fluorine plastic lined pump, and the silicon carbide ceramic lined pump.

The desulfurization pump made of metal material boast of high strength, good rigidity and plasticity. This type could choose a variety of metal materials, like carbon steel, wear-resistant cast iron, ductile iron and so on.

The desulfurization pump lined fluorine plastic, the toughness is good. But the high temperature resistance of fluorine plastic is limited, and the service life is shorter.

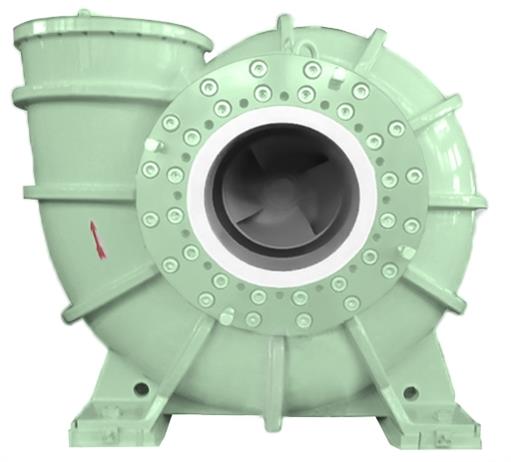

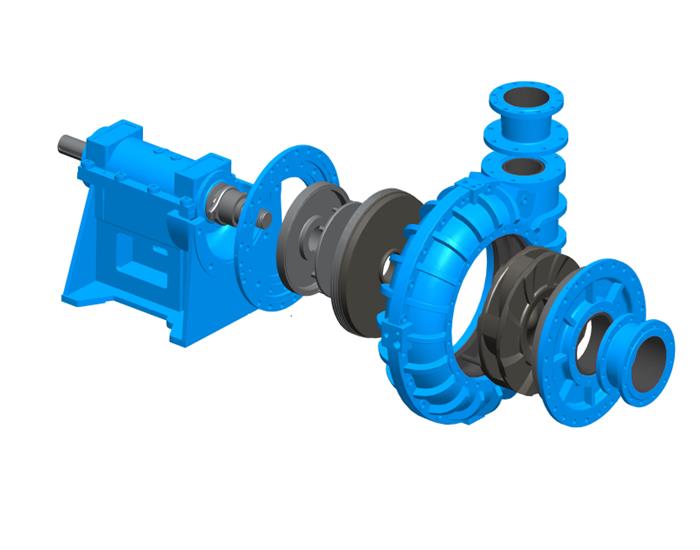

The desulfurization pump lined silicon carbide ceramic has high strength, high hardness, high temperature resistance, corrosion resistance and wear resistance. A silicon carbide lining desulphurization pump, is a metal shell, lined with ceramic, the impeller of the pump with metal as the skeleton, the outer layer covered with SiC ceramics.

Non-pressure sintered SiC ceramics

Non-pressure sintering of SiC ceramics can be divided into solid phase sintering and liquid phase sintering. The strength and other mechanical properties of solid-phase sintered SiC are usually not excellent, with the strength ranging from 290 to 440MPa and the fracture toughness ranging from 3.4 to 4.4MPa.m1/2.

The relative density of SiC ceramics sintered in liquid phase increases from 98% to 99% and is almost completely dense. The strength of the material is increased from 600MPa to 707MPa, and the fracture toughness is increased from 8.1 MPa.m1/2 to 10.7 MPa.m1/2. Non-pressure liquid phase sintering of SiC ceramics is especially suitable for use in high performance requirements.

Silicon carbide lined desulfurization pumps belong to large flow, medium head mixed flow pump, suitable for conveying corrosive, abrasive medium. Based on the high efficiency hydraulic model of metal pump, coupled with the strong wear resistance and corrosion resistance of non-pressure sintered silicon carbide, so that the service life of a desulfurization pump is greatly extended.

Adopting silicon carbide lining desulfurization pumps could save energy, reduce equipment maintenance costs and reduce operating costs.