Learn - Jan. 08, 2025

In petroleum, petrochemical, refineries and chemical industries, it is always necessary to transport high-temperature and high-pressure fluids. Centerline-supported chemical centrifugal pumps that can withstand high temperatures and high pressures will be applied.

Centerline-mounted single-stage overhung pumps shall be designated pump type OH2. They have a single bearing housing to absorb all imposed upon the pump shaft and maintain rotor position during operation. High temperature high pressure process pumps are crucial equipment in petroleum chemical production. They operate under severe conditions and have high requirements for the dynamic equipment. They need to pump high-temperature and high-pressure medium, which imposes very high demands on the performance of Centerline-mounted centrifugal pumps.

When transporting high-temperature medium, the transfer of heat will not only influence the temperature distribution of the flow wetted components of the pump but also generate thermal loads. Therefore, the petrochemical process pump has a centerline-supported structure, also referred to as the OH2 pump or high-temperature oil pump.

Centerline supported end suction single stage centrifugal pumps have very high requirements for the material of the pump parts, the support structure and the seal system. Obviously, only high temperature and high pressure OH2 pumps with outstanding performance can meet the customer's requirements.

OH2 Centerline mounted centrifugal pump ensure the smooth transportation of high-temperature and high-pressure medium from the following three aspects:

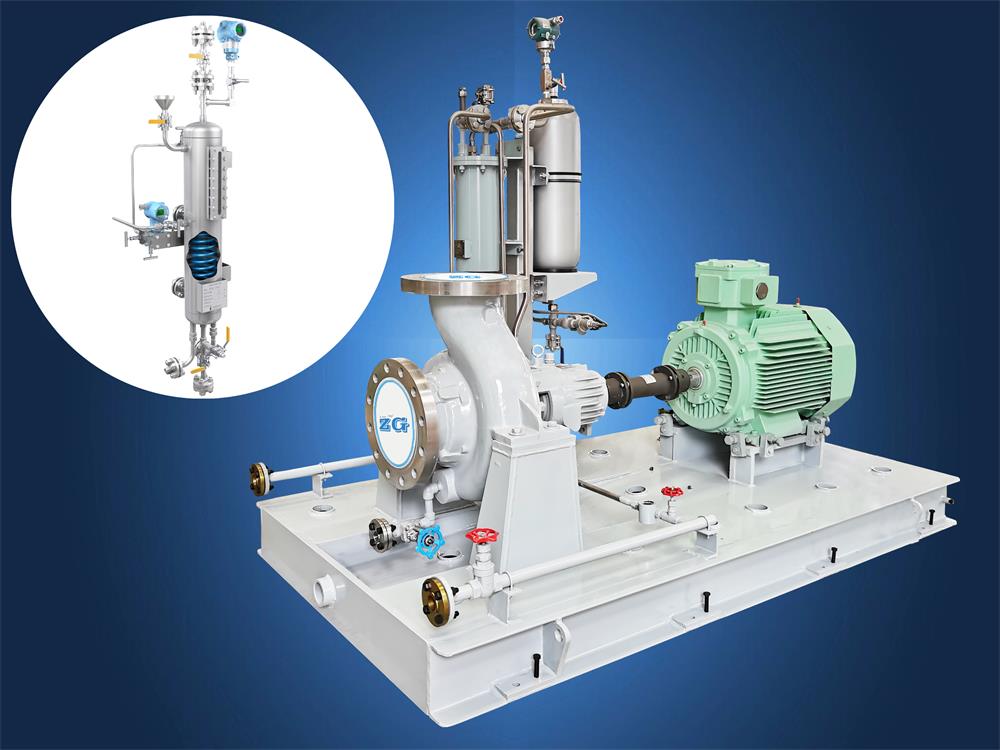

OH2 Centerline mounted centrifugal pumps are often used in the petroleum and petrochemical industry, which are frequently referred to as high-temperature oil pumps. However, centerline-mounted centrifugal pumps are not only applied in the petrochemical industry but also frequently seen in general industry. Our high-temperature brine pumps and high-temperature hot water circulation pumps are also best-selling products. Due to the differences in medium temperature and pressure, the selected pumps vary greatly in appearance and performance parameters. Our professional sales and technical engineers can assist you in choosing the most suitable OH2 pump for your actual operating conditions to handle high-temperature and high-pressure conditions.

● HIGH-TEMPERATURE RESISTANT

Temperature variations can cause changes in the mechanical and physical properties of materials. Our materials department has extensive experience in the use of high-temperature resistant materials.

● Carbon steel

● Stainless steel

● Duplex stainless steel

● Super duplex stainless steel

● Special austenitic stainless steel

● Titanium

● Titanium alloy

● Hastelloy alloy

● Hastelloy A

● Hastelloy B

●Hastelloy C

● HIGH-PRESSURE RESISTANT

Components that withstand high pressure, such as the pump body, impeller, and shaft, require materials with high strength and high toughness to cope with the mechanical stress caused by high pressure. Ensure that the cast components have no cracks or shrinkage cavities through radiographic and ultrasonic testing.

● CORROSION-RESISTANT

With the large-scale and industrialized development of petrochemical plants and the increasing demand for longer operation cycles, the sulfur and acid content in crude oil has gradually increased. This situation has forced the petrochemical industry to require high temperature and high pressure oil pumps to have excellent corrosion resistance. We know that in the materials industry, materials with excellent corrosion resistance are not difficult to find. However, in practical applications, corrosion problems of petrochemical pumps keep emerging, and the problem lies in the fact that the medium does not match the most suitable material. As a professional pump manufacturer, we provide comprehensive professional services to address the corrosion problem faced by customers. We have established a dedicated team for each individual customer, including pre-sales personnel, technical personnel, testing personnel, and after-sales personnel. We have numerous successful cases of solving high-temperature and high-pressure corrosion problems of centerline mounted process pumps.

The support component is an important part of the OH2 Centerline mounted end suction centrifugal pump.

Centerline supported base plates prevent distortion and misalignment caused by high temperature and pressure. When transporting high-temperature medium, the conventional design of the support structure is prone to deformation and cracking, which can cause friction between the impeller and the pump casing, eventually leading to pump damage and making the equipment unusable. The OH2 Centerline mounted end suction centrifugal pump unit adopts a central support structure. The pump body is fixedly installed on the support, and the support is fixedly connected to the base. The support bears the pump body, impeller, pump cover, bearing box and other components and the corresponding loads. The support and base plate are made of high-quality alloy steel material. The material characteristic parameters are: density 7.8g/cm³, Poisson's ratio 0.3, elastic modulus 200GPa, yield strength 242MPa, tensile strength 400MPa.

For high-quality centerline mounted centrifugal pumps, mechanical seal is a very crucial component, and the service life of mechanical seal is a key concern for us. Extending the service life of mechanical seals is an achievement we have already made. The outstanding performance of petrochemical centrifugal pumps helps end users save energy and reduce consumption, minimize the loss of crude oil processing volume, reduce maintenance frequency, lower maintenance costs, and ensure the stable and long-term operation of the equipment.

PLAN21 Forward flush plan with heat exchanger

PLAN32 Injection flush plan

PLAN52 Storage tank buffer liquid circulation flush plan

PLAN53A Tank blockage liquid circulation flush plan

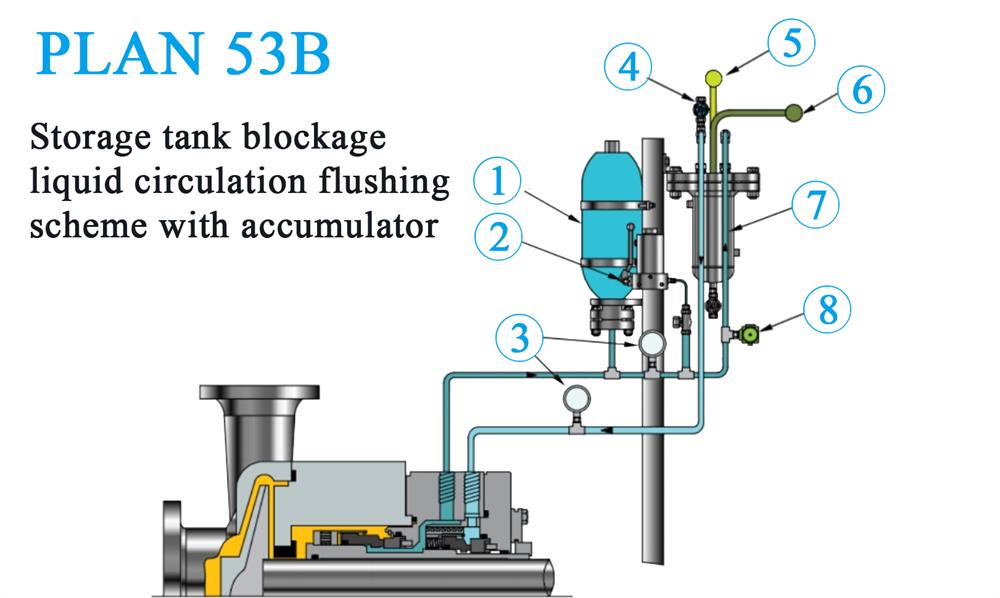

PLAN53B Liquid circulation flush plan for accumulator tank blockage

PLAN54 Cooling water flush plan

| 1 Accumulator | 2 Manual fluid replenishment pump | 3 Pressure gauge |

| 4 Exhaust valve | 5 Cooling water outlet | 6 Cooling water inlet |

| 7 Heat exchanger | 8 Pressure switch |

The auxiliary device for mechanical seal transforms severe working conditions into an environment suitable for the operation of mechanical seals, enhancing the performance of mechanical seal and the safety factor of equipment operation, making zero leakage of the medium possible.

The seal chamber is compatible with multiple sealing configurations and is suitable for various operating environments, including the most demanding working conditions. A full complement of API 610 seal flush piping plans is available, ensuring reliability in different application.

● External injection flush plan

● Non-pressure double end auxiliary plan

● Pressured double end auxiliary plan

● External injection flush combined with back cooling flush plan

● External injection flush combined with pressurized double-end flush plan

● External injection flush combined with oil station circulation system plan

● Non-pressure gas seal combined with venting plan

● General wet seal auxiliary plan

● Heat exchange bypass self-flush combined with pressurized double-end face seal auxiliary plan

● Bypass self-flush combined with pressurized double-end face seal auxiliary plan

The choice or combination of multiple flush plans makes the centerline mounted process pump versatile for a wide range of applications.

Drawing on our abundant past success experiences, our sales team and technical engineers are here to craft the optimal flush plans tailored just for end users. This not only helps extend the life of mechanical seals but also ensures the reliable transportation of high-temperature and high-pressure fluids, even in the most challenging conditions. We see ourselves as a comprehensive services supplier who not only takes care of manufacturing high-quality pumps and pump set components but also ensures that all parts work together smoothly as a whole, configurating mechanical seal auxiliary devices and jacketed casings and covers.

Guide To Selecting The Right Slurry Pump For Your Application

Application of High-temperature Hot Water Circulation Pumps in Metallurgical Industry

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

Zigong Pump & Valve 2021 Marketing Work Conference was Held Successfully