Learn - Jun. 29, 2023

A forced circulation axial flow pump is the key equipment in the diaphragm method caustic soda evaporation device. There were some problems in that forced circulation axial flow pump used in this chemical plant. In June 2021, Technical communication had started between their engineers and our technicians, and purchased a new horizontal axial flow pump produced by our company two months later.

Working Condition Parameters:

Flow rate: 2300 m3 /h

Head: 4.4 m

Medium: caustic soda solution containing NaCl particle, the concentration of NaOH is 22. 71% ~ 50. 00%

Specific gravity: 1.66

Temperature: 121~144 ℃

Problems Before Renovation:

1. The service life of the mechanical seal was too short, and the maintenance frequency was 2.5 to 3 months.

2. The impeller and pump casing had corrosion and abrasion, and the material of flow parts of the original axial flow pump is duplex stainless steel 2205.

3. There was no designed shaft sleeve for the shaft. The part of the shaft in contact with the medium was easy to corrode.

4. Adopting bearing grease lubrication, lubrication and heat dissipation performance was poor.

5. The stability of the pump unit was poor during operation, and the noise was relatively large.

Replace New Forced Circulation Axial Flow Pump

1. Select unbalanced double-end mechanical seals and equip P54 cooling water flushing plan for them. The sealing material is tungsten carbide which could resist high temperature and strong alkali. Tungsten carbide has very high strength and hardness, excellent wear resistance and corrosion resistance, impurities and crystals are difficult to damage it; Moreover, tungsten carbide has excellent thermal conductivity, small linear expansion coefficient, and can maintain good sealing performance at higher temperatures.

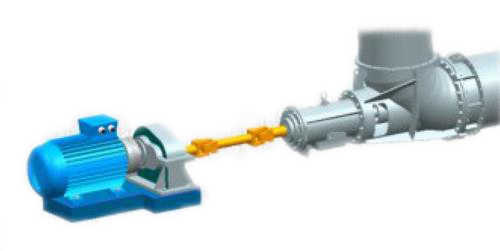

2. The material of flow parts of the forced circulation axial flow pump is Nickel. Pump model is ZW550. The axial flow pump is mounted by suspension. Installation type is “pump + motor + reducer + universal joint”. The motor base needs the grouting foundation. The weight of the pump body is supported by the pipeline and driven by the triangle belt. There’s no need to have expansion joint. At the same time, we set up a short section at the horizontal pipeline connected with the pump to facilitate the inspection of impeller, mechanical seal and other components.

3. The shaft adds shaft sleeve to prolong the lifetime.

4. The lubrication method is oil lubrication, increase the internal cooling coil, further reduce the lubricating oil temperature, and greatly improve the wear resistance and bearing capacity of the bearing.

5. After the installation of the new forced circulation axial flow pump, the operation has been smooth with low noise and low vibration. After one year of operation, there’s no maintenance record of the axial flow pump, no leakage of the mechanical seal, and the feedback from the customer is very satisfactory.

A forced circulation axial flow pump is the core equipment of the evaporation system. We have to replace the new pump for the owner without changing the original pipeline design, and solve all the previous problems. We provide comprehensive services for chemical plants, dedicated to the design and transformation of fluid delivery for customers. Especially for the chemical pump renovation project, there are many problems involved. We listen to them carefully for the existing problems, we understand the particular challenges and difficulties of each and every project. This is the only way we can find an optimum solution together with our customers and overcome every challenge and we always try our best to do. Extensive experience and highly professional enable us to develop highly specialized and tailored targeted solutions for our customers.