Learn - Feb. 17, 2023

Sulfur pump, is known as liquid sulfur pump, is the key equipment in the process of liquid sulfur transportation, because the temperature of the conveying medium is between 130 ~ 150 ℃, is also known as high temperature liquid sulfur pump, or high temperature vertical submerged sulfur pump, vertical liquid sulfur pump.

Submerged liquid sulfur pump is a special form of insulation pump for conveying molten sulfur (liquid sulfur). The physical and chemical properties of sulfur are light yellow crystal, insoluble in water, melting point is 112℃, boiling point is 444.6 ℃, density is 1.96 g/cm3. In the chemical industry, sulfur is the raw material for producing sulfuric acid. Sulfur ambient temperature is a solid form, solid is not easy to convey in chemical plant, so steam is used to heat sulfur to the melting point, become liquid sulfur. The liquid sulfur should be kept in the range of 130 ~ 150 ℃. Below this range, the liquid sulfur will crystallize and affect the subsequent transportation. Therefore, the vertical sulfur pump needs to be equipped with insulation structure. High temperature liquid sulfur pump is a special vertical liquid sulfur thermal insulation pump which is equipped with thermal insulation device on the basis of vertical submerged pump.

The Vertical submerged chemical pump is a special corrosion resistant vertical centrifugal pump, flow parts of submerged pumps (impeller, pump casing, pump cover, pump shaft and support parts, etc.) immersed in the medium. The pump is installed under the foundation, and the motor is installed on the platform above the liquid level of the transmission medium. Liquid sulfur pumps could be considered as a special form of vertical submerged pumps, compared with horizontal centrifugal pumps, vertical submerged liquid sulfur pumps have the features of small covering area, convenient starting.

The structure of a liquid sulfur pump adopts vertical suspension structure. The impeller is immersed in the sulfur liquid sum, and the medium discharged from the impeller. In order to ensure the liquid fluidity of the sulfur liquid in the flow process and keep the temperature of the sulfur liquid between 135-145℃, it is necessary to add thermal insulation equipment on the pipeline which the sulfur liquid flows, and the liquid sulfur pump needs to add thermal insulation jacket.

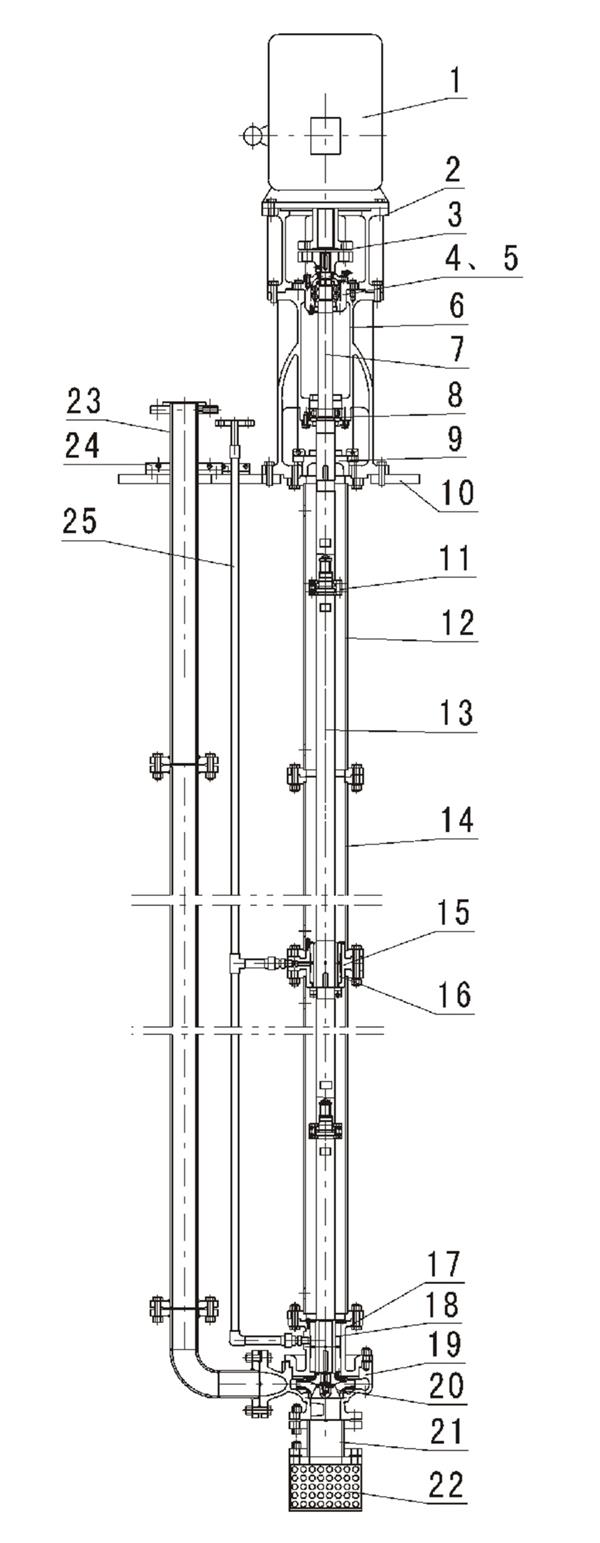

The structure of the liquid sulfur pump is as follows:

| 1.Motor | 2.Intermediate support | 3.Coupling | 4. Bearing sleeve | 5. Bearing |

| 6.Bearing block | 7.Shaft | 8.Bearing | 9.Sealing component | 10.Base plate |

| 11.Shaft hooping | 12.Supporting tube | 13.Intermediate shaft | 14. Supporting tube | 15.Packing sleeve |

| 16.Integral packing | 17.Pump cover | 18.Integral packing | 19.Pump casing | 20.Impeller |

| 21.Liquid refilling pipe | 22.Filter mantle | 23.Drain pipe | 24.Hooping | 25.Flushing pipe |

The upper part of the pump is provided with a pair of deep groove ball bearings, which are used to bear the axial force generated in the operation of the pump, and the guide bearings are provided in the liquid part of the pump, which are used to bear the radial load, limiting the radial freedom of shafting. Pump shaft and outer tube, bushing tube is composed of multiple sections, the middle drive shaft is a sleeve type shaft structure; The guide bearing is lubricated by self-lubricating method, that is, the medium conveying pipeline is drawn out at the pump outlet flange, so that the washing liquid flows to the sliding bearing, lubricate the bearing and take away the heat generated by friction, and reduce the bearing temperature. In addition, in order to prevent the sulfur liquid medium from crystallizing out at the guide bearing when the pump is not started, affecting the normal start of the pump, it is necessary to set up a thermal insulation chamber at the guide bearing, and steam is heated in advance before starting the pump, so as to prevent the bearing from poor lubrication.

In order to prevent the precipitation of sulfur liquid before the pump start, it is also necessary to carry out thermal insulation treatment in other important positions. The thermal insulation cavity is designed at the guide bearing, and the cavity is filled with hard polyurethane foam stock solution.

We are professional partner for the chemical industry for a long time.

From tyres for cars to clothing and detergents, almost every item in our daily lives is manufactured using products from the petrochemical and chemical industries. Their production presents special challenges: chemical plants are complex systems that operate at temperatures, often using corrosive toxic liquid. As a result, our customers in chemical industries often have demanding and diverse requirements.

In the transportation of sulfur, sulfuric acid at high temperature we have rich experience to deal with various requirements. Not only do our service engineers ensure reliable and efficient functioning of vertical high temperature sulfur liquid pumps, they also provide support in planning, installation, commissioning, repair and regular maintenance of our pumps and associated equipment.