Learn - Jun. 27, 2023

Titanium, Titanium Alloy has low density, high specific strength, and excellent corrosion resistance.Titanium pumps have excellent performance of corrosion resistance, and be widely used in chemical industry. Titanium pumps and titanium alloy pumps are widely used in the chlor-alkali industry, salt industry, and other chemical industries with corrosive liquids. We have reach experience of the characteristics of titanium and we choose the appropriate titanium or titanium alloy for our customers.

Titanium, Titanium Alloy has low density, high specific strength, and excellent corrosion resistance.Titanium pumps have excellent performance of corrosion resistance, and be widely used in chemical industry. Titanium pumps and titanium alloy pumps are widely used in the chlor-alkali industry, salt industry, and other chemical industries with corrosive liquids. We have reach experience of the characteristics of titanium and we choose the appropriate titanium or titanium alloy for our customers.

For titanium castings, we adopt the technology of lost foam cladding casting. This titanium casting technology has the following advantages: ① The design limitations of titanium castings are small, and the use of integral model coating to prepare castings greatly improves the freedom of casting design. At the same time, through the combination of model cutting edges, titanium castings with highly complex structures can be produced, such as impellers of titanium liquid ring vacuum pumps and the complex components of titanium plunger piston pumps. ② The oxidized ceramic shell has low thermal conductivity, good yield and smooth surface inside the cavity, which can solve the problems of flow marks, cold insulation and cracks of graphite titanium castings, and make the filling performance and surface roughness reach or close to the level of investment casting. ③ Core-free, it can avoid the problem of uneven wall thickness caused by inaccurate core position or misalignment, and make sure high dimensional accuracy. ④ The most basic requirements ensure that the surface of titanium castings is smooth, the dimensional accuracy is high, there is no burr flash, the process is simple, and the production cycle is greatly shortened.

In chemical industry, corrosion is a major problem, the main cause of equipment damage is corrosion. titanium in corrosion resistance, wear resistance, erosion resistance, has extremely excellent performance, service life is carbon steel, stainless steel and cast iron equipment several times, dozens of times.

These medium sections (chlor-alkali, soda ash, salt making, liquid ammonia, petrochemical fiber, inorganic salt ) almost always use titanium equipment in chemical industry. Common refer to titanium centrifugal pumps, titanium horizontal axial flow pumps, titanium liquid ring vacuum pumps, titanium plunger pumps.

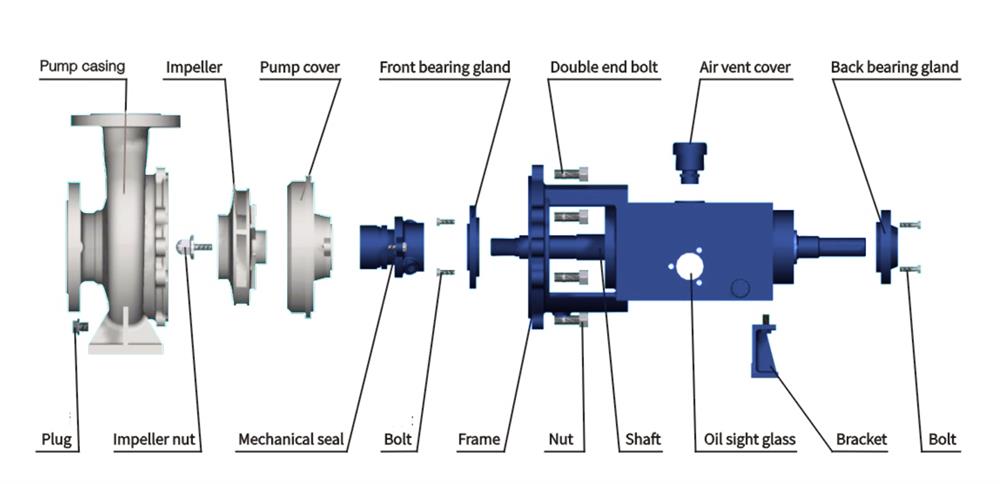

A titanium pump is a kind of pump which flow parts (pump casing, impeller, pump gland and other accessories) are made from titanium or titanium alloy. Titanium or titanium alloy has the characteristics of corrosion resistance, small specific gravity, high strength, high or low temperature resistance. Therefore, the titanium pumps have excellent corrosion resistance, and can handle most of organic acids, inorganic acids, organic compounds and alkali and salt solutions.

Titanium chemical process centrifugal pumps by usually said are single stage, single suction cantilever structure. Titanium centrifugal pumps are widely used in the chlor-alkali or salt industry, if the temperature of the medium is high, the centerline support OH2 type is recommended to resist high temperature and highly corrosive.

Titanium impeller and titanium pump casing have been optimized with good hydraulic model, wide efficient range, high efficiency and energy saving. In order to cope with more complex working conditions, titanium materials can be selected: TA2, TA9, TA10. Titanium centrifugal pumps are suitable for transporting NaOH solution, urea methylammonium, liquid ammonia and other alkaline solution.

When dealing with high temperature corrosive fluids, the titanium centerline supported centrifugal pumps are recommended. This OH2 type centerline-mounted single-stage overhung titanium pumps always be designed double volute casing to increase the corrosion margin. The titanium pulp pump with open impeller or semi-open impeller is used for conveying medium with seldom particles.

Regarding to salt making industry, including vacuum evaporation salt production, the use of multi-effect evaporation, MVR evaporation salt device, hot pressing salt production, which would use forced circulation horizontal axial flow pump, because of the highly corrosive of brine, the material of flow parts of horizontal axial flow pumps should adopt corrosion-resistant materials. Titanium horizontal axial flow pumps are the ideal device for salt making industry.

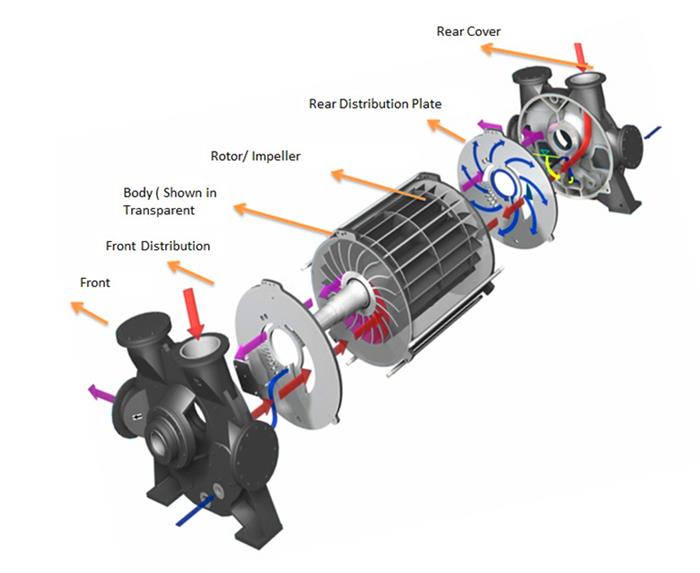

Liquid ring vacuum pump is a kind of fluid mechanical equipment which uses liquid as working fluid to suction and compress gas. The flow parts adopt material of titanium or titanium alloy , which is called a titanium liquid ring vacuum pump. The titanium liquid-ring vacuum pump could handle with corrosive gases, could use corrosive liquids as working fluids, is the ideal transport equipment in the chlor-alkali industry.

A titanium impeller is the most important part of a titanium liquid ring vacuum pump. The structure of titanium impeller castings is complex, the difference of wall thickness is large, the blade parts are thin, the number of blades is large, and the shaft holes and the buckle assembly parts are thick. The casting accuracy of the titanium impeller is CT8 level, and the surface of the impeller is not allowed to have surface cracks and shrinkage cavities. The casting size of titanium alloy vacuum pump is required to be accurate and the flow path surface is smooth. Our foundry owns titanium alloy lost foam cladding casting technology, has high-precision automatic manufacturing processing equipment. In the process of manufacturing titanium liquid ring vacuum pumps, the titanium impeller is the most complex part, asking for light weight and high precision during the casting process, and we have the ability to do the best.

Reciprocating plunger pumps are widely used in crude oil transportation, natural gas, petrochemical, chemical industry. The working principle of the reciprocating plunger piston pump is that the piston is used to do reciprocating movement in the cylinder block, and the working volume of the seal is changed to achieve the oil absorption and oil pressure of the pump. The high pressure reciprocating pump has the advantages of good sealing performance, high volumetric efficiency, high matching accuracy, and reliability under high pressure conditions, which are confirmed by many end users. Plunger pump sleeve, plunger, flange cover, pump body, transmission pin using titanium forging parts or titanium alloy forging parts, for corrosive media high pressure transport. The rotating sleeve, plunger piston, flange gland, pump body, drive pin and other accessories of a plunger pump are made of forging part or titanium alloy forging part could be used to convey high pressure corrosion medium. That is a pretty cool device. Quench forged titanium parts have characteristics of high pressure bearing, high corrosion and high temperature resistance in harsh conditions.