Learn - Mar. 20, 2021

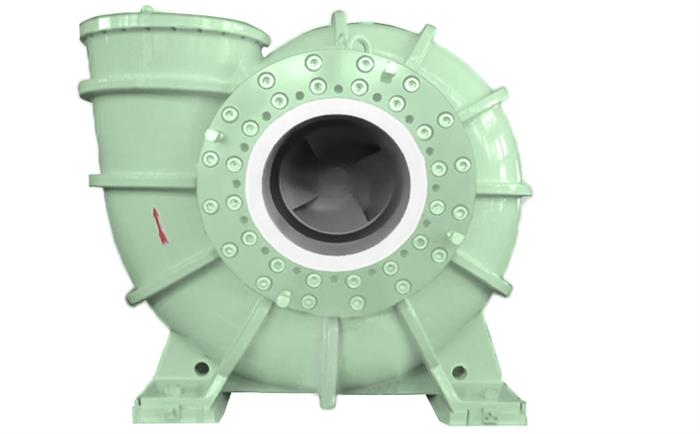

A mixed flow pump is a centrifugal pump with a mixed flow impeller. The specific speeds lie between 35 and 80 rpm for low-speed mixed flow pumps and between 80 and 160 rpm for higher-speed mixed flow pumps (in special cases even higher). Mixed flow pumps cover the transition range between radial flow pumps and axial flow pumps (e. g. propeller pumps).

The impellers of mixed flow pumps with a low specific speed are combined with an annular or volute casing; those of mixed flow pumps with a higher specific speed are combined with a diffuser and a tubular casing.

A Horizontal Mixed Flow Pump is a kind of pump between single stage end suction centrifugal pump and horizontal axial flow pump. It has the characteristics of large flow rate, medium head, high efficiency and wide application range. Therefore, it is widely used. Volute mixed flow pump, also known as horizontal mixed flow pump has the advantages of short axial size, high operation stability and reliability of the unit.

The flow rate of the horizontal mixed flow pump is 12.5 ~ 20,00L /s; The head is H =3 ~ 30m, some can reach 60m; Caliber of 100 ~ 1500mm, customized large mixed flow pump caliber up to 5000mm; The specific speed range is usually NS =300-500, and the highest speed is NS =1110 at present; Speed n= 980-2900R /min.

When the prime mover drives the impeller to rotate, the action of the liquid is both centrifugal force and axial thrust, which is integrated with the centrifugal pump and axial flow pump, and the liquid is inclined to flow out of the impeller. So it is a kind of pump between the centrifugal pump and axial flow pump. Mixed flow pump than the speed higher than the centrifugal pump, lower than the axial flow pump, generally between 300-500. Its head is higher than the axial flow pump, but the flow rate is smaller than the axial flow pump, larger than the centrifugal pump. Seal packing seal or mechanical seal. Material is corrosion-resistant material.

● In fields you may be familiar with, desulfurization pumps are commonly used, which is another term for horizontal mixed flow pumps. These pumps play a crucial role in wet flue gas desulfurization processes in thermal power plants. They must endure both the corrosive effects of acidic liquids and the abrasive impact of particles. Our high-efficiency silicon carbide-lined desulfurization pumps are specifically designed to address these challenges, setting a new industry standard for corrosion and wear resistance.

● The horizontal mixed flow pump made from cast iron can be used in farmland drainage and irrigation, flood prevention and drainage, water conservancy projects, sewage treatment, power station (coal-fired power station, nuclear power station, storage power station, tidal power station) cooling system.

● The chemical horizontal mixed flow pump is suitable for solid liquid two-phase flow of complex processes.The slurry pump containing CaCO3 solid particles is a typical mixed flow pump. Learn more about chemical mixed flow pump.

● Medium, chemically neutral or aggressive medium for conveying clean and contaminated media.

● Forced circulation, seawater aquaculture, urban gas engineering, water treatment system in chemical industry process.

● Vertical mixed-flow pumps are used in water diversion projects for water conservancy. In temperate regions, water levels fluctuate seasonally. Adjustable blade guide vane vertical mixed-flow pumps handle variable head requirements effectively.

Mixed flow pump is a kind of "pulling" type structure of the pump, check and disassembling the impeller and shaft seal, no and the pump body is connected with the pipeline apart. The pump shaft is equipped with precision machining, with a thin oil lubrication bearing, shaft sleeve is arranged in the stuffing box cover. Oil bearing box, a constant level oiler to control.

Pump body of the foot can withstand any load from the pipeline, and the direct transmission to the foundation. In this way, the rotor will not be subjected to load due to the pump bending, so as to ensure the best use of the bearing life.

Due to the larger flow area, thereby reducing the blocking. The direction of rotation of the pump, from the driver side to see, for the clockwise direction. Motor or internal combustion engine is driven by power. The pump device can be equipped with a complete bleeding device, which is beneficial to the exhaust of the suction pipe.

The optimum specific speed range for tubular casing mixed flow pumps with regard to construction costs and efficiency is not clearly defined. However, from approximately 130 rpm upwards, the tangential component of the absolute velocity at the impeller outlet becomes so small in comparison with the flow velocity at the pump suction nozzle that the end cross-sections of the volute or annular casing required to convey the flow (see Flow rate) would become disproportionately large.

For this reason, mixed flow pumps with higher specific speeds are usually designed with an axial tubular casing and an "onion type" or axial flow diffuser through which the fluid flows towards the discharge elbow and the pump discharge nozzle.

The range of heads of mixed flow pumps with tubular casing complements that of the propeller pump at the top end of the head range. As the circumferential velocity of a mixed flow impeller is restricted to 25 to 30 m/s to prevent cavitation (see Suction characteristics), the mixed flow pump can only exceed its maximum head of H = 60 m if it is designed as a multistage pump. In practice, the number of stages is limited to two or three.

The above information is provided by a mixed flow pump manufacturer.