Learn - Sep. 03, 2020

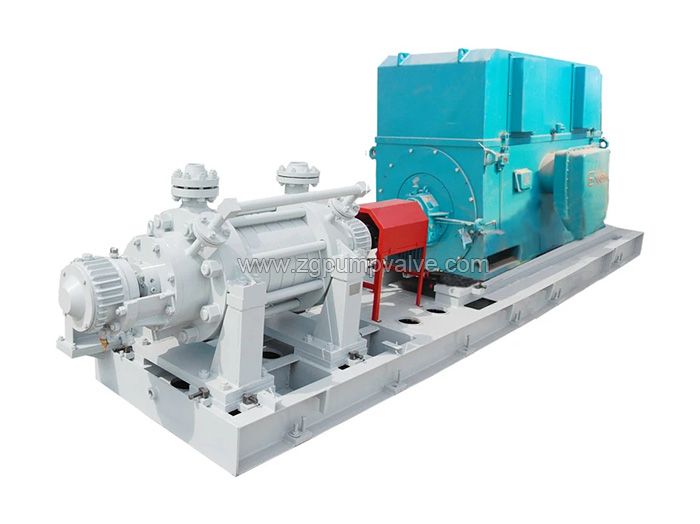

Multistage pumps are mainly used for high-temperature condensate recovery, boiler water supply, and water supply and drainage for factories, cities, and mines.

Multistage pumps are horizontal, multistage segmented, single-suction pumps, used to transport clear water without solid particles or liquids with physical and chemical properties similar to clear water. The head is 25-200 meters, and the head can be increased or decreased according to user needs The number of pump sections and maintain excellent sealing performance.

Multistage pump composition

The multistage pump is mainly composed of four parts: stator, rotor, bearing, and shaft seal:

1. The stator part of the multistage pump is mainly composed of the suction section, the middle section, the discharge section, and the guide vane. There are tension bolts to clamp each section to form a working room. The D-type pump generally sucks in horizontally and discharges vertically upward; when used in oilfield water injection, the inlet and outlet of the pump are vertically upward. The outlet and inlet of the DG multistage pump are vertically upward.

2. The rotor part of the multistage pump is mainly composed of the shaft, impeller, balance disc, and shaft sleeve. The axial force is balanced by the balance plate.

3. Multistage pump bearings are mainly composed of bearing bodies, bearings, and bearing glands. The bearings are lubricated with grease or thin oil.

4. The shaft seal of the multistage pump adopts a soft packing seal, which is mainly composed of the sealing box body, packing, and water retaining ring on the water inlet section and the tail cover. D type pump seal water comes from the pressure water in the pump. The sealing water of the DG pump comes from the external water supply.

5. Multistage pump rotation. The pump is directly driven by the prime mover through elastic coupling. Looking at the pump from the prime mover, the pump rotates in a clockwise direction. D and DG pumps are horizontal single-suction multistage centrifugal pumps. For transporting clean water (with impurities less than 1%, particle size less than 0.1mm) or other liquids with physical and chemical properties similar to water. The medium temperature of the D-type pump is less than 80℃, suitable for mine drainage, oil field water injection, factory, and urban water supply and drainage. Oil field water injection pumps use different materials according to the corrosiveness of the medium. The medium temperature of the DG pump is less than 105℃, which is suitable for all kinds of boiler feed water.

The above information is provided by the multistage pump manufacturer.