Learn - Oct. 11, 2023

Screw pumps are used to transport high-viscosity liquids, pastes, neutral or corrosive liquids, liquids mixed with air, liquids with foam, and even medium containing fiber solid components. The screw pump is also known as Progressing Cavity Pump, Mono Pump, and Rotary Positive Displacement Pump, according to the different structural form which are divided into single screw pump, double screw pump and three screw pump.

By selecting different materials like carbon steel, AlSl 316 stainless steel, 22Cr duplex and 25Cr duplex stainless steels to suit a wide range of applications, the goal is to provide the best viscous medium handling solution for end users. Progressive cavity pumps perfectly handle with viscous mixtures in petroleum, water management, hydrocarbon sludge, and other industries.

A single screw pump belongs to positive displacement pumps, whose wetted parts are composed of stator and rotor. The rotor is a screw with large lead, large tooth height and small inner diameter of thread. The stator is an elastic bushing with double-headed spiral. The rotor and the stator cooperate with each other to form a sealed cavity without communication. When the rotor turns inside the stator, the cavity progresses spirally along the axis of the pump without changing either shape or volume.

Working principle of a single screw pump

When the rotor rotates in the stator, the sealing cavity moves from the suction end to the discharge end, and the high viscosity medium transported is discharged continuously in the sealing cavity. Screw pumps are reversible and could discharge mud or sludge in reverse.

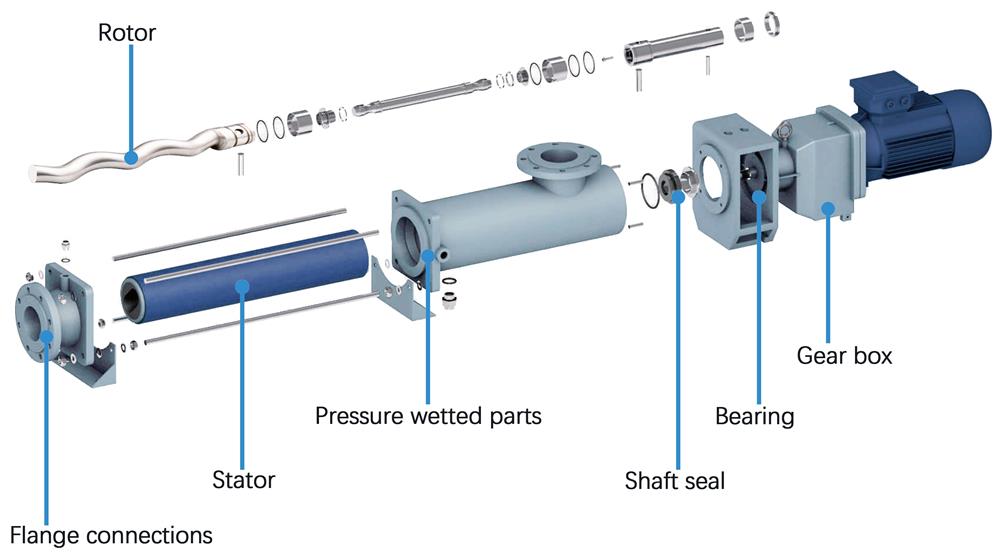

The structure of the single screw pump

Connections ANSI/ASMEB16.5 flange connections

Rotor The pump's rotor is manufactured from high strength carbon steel, and could select stainless steel, duplex stainless steel, titanium, or other materials for coping with corrosive, abrasive fluids. The rotor is coated to reduce the friction between rotor and stator.

Stator The stator is made from nitrile(NBR) or fluorocarbon elastomer. Both ends are sealed and flanged, and the rubber bushing and metal bushing are connected into one.

Pressure wetted parts That is welded construction with materials options to suit a wide range of applications.

Shaft Seal Single or double cartridge mechanical seal could be selected according to the medium.

Bearing Bearings own longer lifetime and better grease lubrication.

Gear box Helical gear reducer, minimum service factor 1.5.

Application

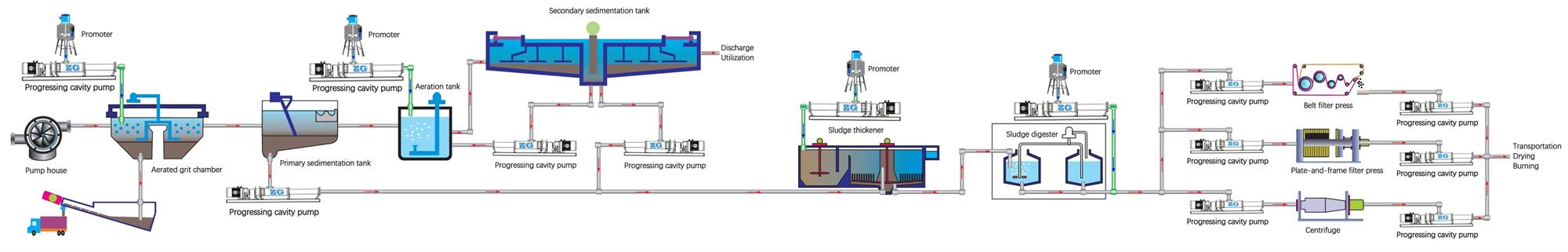

Waste water treatment

The sludge produced in all aspects of the sewage treatment plant, including concentrated sludge, floating sludge, dilute sludge and dehydrated sludge, which are transported and treated by single screw pumps. The single screw pump meets the requirements of complete closure, no leakage, no odor, continuous operation and automatic management when conveying sludge in medium and short distance.

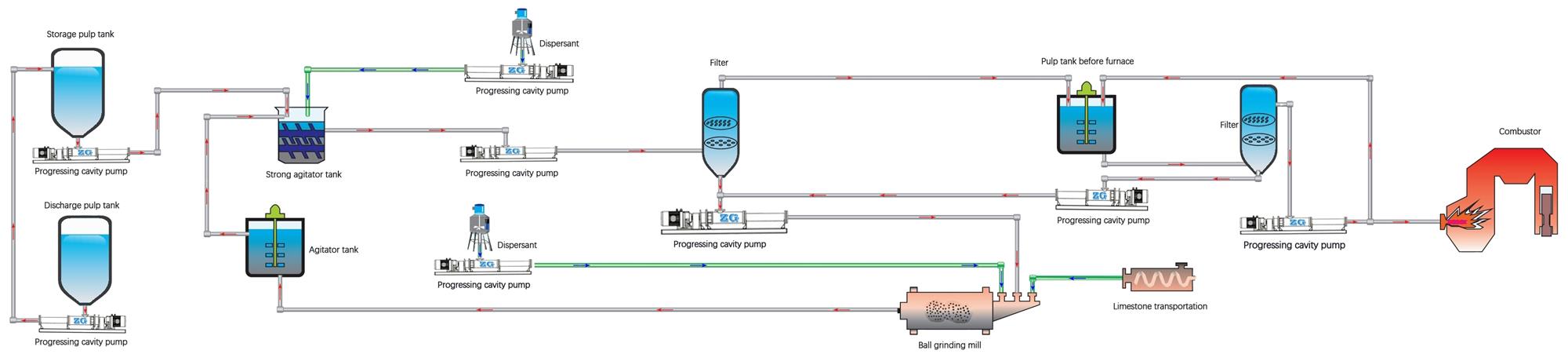

Coal water mixtures, coal water slurry and coal water transportation

The coal water slurry refers to the mixture of pulverized coal and water, and a certain amount of additives are added. The phenomenon of soft precipitation and stratification should be avoided during the transfer of coal water mixtures. The single screw pump is the best choice for coal water mixtures transportation because the volume of the pump chamber remains constant and the medium is almost not stirred in the pump.

Pulp, paper and board industry

Stoichiometry; Coating and coloring process; 10~25% medium concentration pulp transport

Oil, gas, crude oil and other petroleum industry

Oil and gas mixed transport;

Oil-water separation and waste oil recovery system;

Polymer transport.

All kinds of chemical paste;

All kinds of milk;

All kinds of suspension;

All kinds of gas-containing and solid-containing liquids;

All types of media not subject to agitation and shearing.

Production and preparation of titanium dioxide, kaolin, calcium carbonate, etc. in mineral engineering, feed the swirling fluid and filter body; Chemical dosing; Loading and grouting

The flow parts are made of food-grade stainless steel material, which is used in food industry dairy products; Fruit juice, fruit puree, vegetable pulp; Ground meat and condiments.