Learn - May. 28, 2020

Slurry pumps are specially designed and built to convey fluids contain a lot of solids without getting clogged up or wearing out in a short period of time. Whether it's mining sludge, wastewater, sands, limestones or heavy industrial mixtures, slurry pumps are able to handle the pumping process smoothly.

Breakdowns of everything you need to know about slurry pumps will be presented in this guiding article: how they work, their key parts, where they're used, and what to look for when picking the right one for your needs. In the end of this article, you will have a solid grasp of why solids handling pumps are so important and how to choose the best one for your application.

A slurry pump isn't the regular water pump—it's built tough to handle the abrasive and high-solid fluids that would destroy regular pumps in short time. Unlike standard water pumps, slurry type of pumps is designed with high chrome materials, silicon carbide and other reinforced parts to resist wear and tear from abrasive particles.

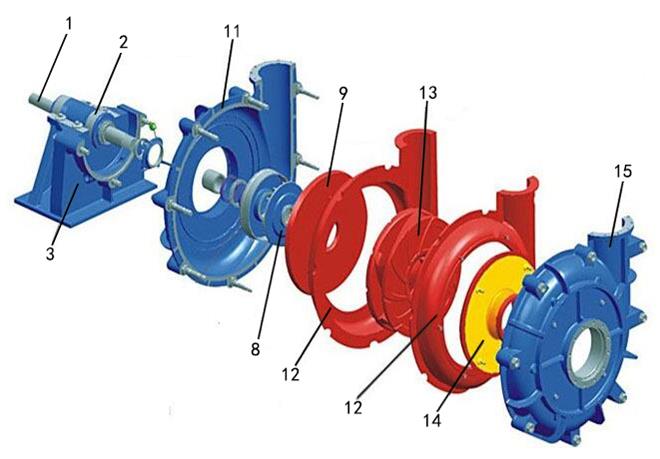

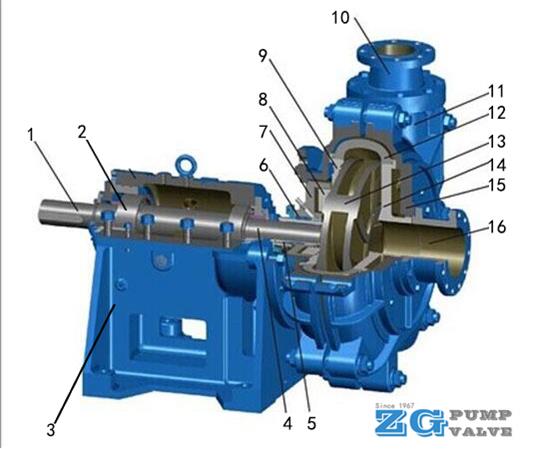

These slurry pumps parts typically including:

● An impeller (the rotating part that moves the slurry)

● A casing (often lined with replaceable rubber or wear-resistant metals to extend its life)

● A shaft seal (to prevent leaks)

● A bearing housing (to keep everything running smoothly)

The wetted parts materials of slurry pumps matter too—high-chrome iron, ceramic (silicon carbide) and wear resistant rubber are common because they can work against harsh conditions. Plus, many slurry mining pumps allow you adjust the impeller clearance to keep efficiency high even if parts wear down slightly.

Slurry pumps operate on the principle of regular centrifugal pumps, meaning they use a spinning impeller to fling the limestone slurry outward, creating pressure that pushes the fluid through the system. Here's the step-by-step of how it works:

3.1 The slurry enters the pump axially (straight into the center of the impeller).

3.2 The impeller spins at high speed, throwing the mixture outward with centrifugal force.

3.3 The casing then slows down the fluid and converts that speed into steady pressure at the discharge nozzle.

This process keeps the slurry medium flowing continuously, even when dealing with thick and abrasive mixtures. But the pump has to generate enough pressure to overcome friction in the pipes and any elevation changes (like pumping uphill).

| 1 Shaft | 2 Bearing assembly | 3 Frame assembly | 4 Shaft sleeve |

| 5 Shaft sealing | 6 Packing | 7 Stuffing box | 8 Expeller |

| 9 Back guard plate | 10 Discharge outlet | 11 Pump casing | 12 Volute liner |

| 13 Impeller | 14 Front guard plate | 15 Pump cover | 16 Suction inlet |

Let's take a closer look at the main components that make these pumps so durable:

Impeller– The rotating part with vanes that moves the slurry. Different designs handle different flow rates and pressures.

Casing– The outer shell that holds everything together and directs the flow. It's often lined with wear-resistant materials.

Shaft– A strong alloy steel rod that connects the motor to the impeller.

Shaft Seal– Keeps the slurry from leaking out. Options include gland packing (simple but requires maintenance) and mechanical seals (more efficient but more expensive and may require external flush water).

Bearings– Support the shaft and reduce friction. They're chosen based on load and operating conditions.

Base plate– A sturdy frame that holds the pump steady and absorbs vibrations.

Each of these parts plays an important role in keeping the pump running efficiently under tough conditions.

These tough sludge pumps are the essential devices in multiple industries where moving thick, gritty mixtures is just part of the daily work. Let's break down where these slurry pumps are putting in the severe applications:

5.1 Mining Operations

● Hauling ore slurries through processing plants in copper, gold and coal mines

● Handling the dirty work of tailings disposal (those leftover waste materials)

● Working 7*24 in some of the most punishing conditions imaginable

5.2 Dredging Projects

● Sucking up sediment and sludge from harbor bottoms and riverbeds

● Playing crucial roles in land reclamation projects

● Operating completely submerged in some of the gnarliest underwater environments

5.3 Desalination Plants

● Moving the concentrated brine byproducts

● Handling the gritty leftovers after freshwater extraction

● Standing up to the corrosive nature of seawater day in and day out

5.4 Fracking Operations

● Pumping water-based bentonite clay mixtures

● Dealing with abrasive drill cuttings slurry

● Taking the punishment in upstream oil and gas extraction

5.5 Wastewater Treatment

● Transporting thick cellulose fiber mixtures (we're talking 10%+consistency)

● Shuttling materials between different production stages

● Standing up to constant abrasive wear from wood fibers

5.7 Cement and Mineral Processing

● Handling raw ore slurries during initial processing

● Moving limestone mixtures in cement production

● Dealing with some of the most abrasive materials around

5.8 Food Processing

● Managing viscous tomato concentrates (ever seen how thick that stuff gets?)

● Handling brewing byproducts in beer production

● Moving sugar beet mixtures in refining operations

● Proving that even food production needs serious pumping muscle

The common points? Wherever there's thick, dirty, abrasive material that needs moving reliably, you'll find slurry pumps getting the job done. They're not glamorous, but when the material gets tough, these are the pumps that step up to the challenge.

Picking the perfect slurry pumps isn't just about grabbing the biggest or most expensive models - it's about matching the pumps to your specific needs. Here's what you need to think about before making your choice:

6.1 Performance Needs

● How much slurry do you need to move? (pump capacity)

● How much pressure is required? (discharge head)

● Don't forget to account for pipe friction and elevation changes in your calculations

6.2 Know the Slurry Characteristics

● How thick is it? (concentration and viscosity)

● How heavy? (specific gravity)

● What's the biggest particle size you're dealing with?

● How abrasive is it? (this determines wear rates)

6.3 Operation Requirements

● How far does it need to lift the slurry? (suction conditions)

● What's your pipe setup look like? (discharge configuration)

● Any space limitations or special mounting needs?

6.5 Environmental Considerations

● What temperatures will it operate in?

● High altitude location?

● Indoor or outdoor installation?

● Need something portable or stationary?

6.6 Safety First

● Is your slurry corrosive? (material selection matters)

● Any toxicity concerns?

● Potential for explosive atmospheres?

6.7 Budget Realities

● Upfront cost vs long-term value

● Expected maintenance costs

● Availability and cost of replacement parts

● Local service and support options

6.8 Tips:

● Always add a 10-15% safety margin to your capacity calculations

● The right metallurgy can double or triple your pump's lifespan

● Don't cheap out on seals - they're the most common failure point

● Talk to manufacturers - they've seen it all and can save you headaches

Remember, the cheapest slurry pump price does not mean it is the most cost-effective. A properly specified slurry pump that matches your exact needs will pay for itself in reduced downtime and maintenance costs. Most quality slurry pump manufacturers offer free application engineering - take advantage of their expertise to get it right the first time. At last, taking the time to properly evaluate all these factors means you'll get a pump that performs reliably for years, not one that's constantly in the repair shop.

Now, let's break down the main types of slurry pumps - because not all pumps are built the same when it comes to handling thick and abrasive mixtures. Basically, there are three main types in the slurry pumping, each with their own specialties.

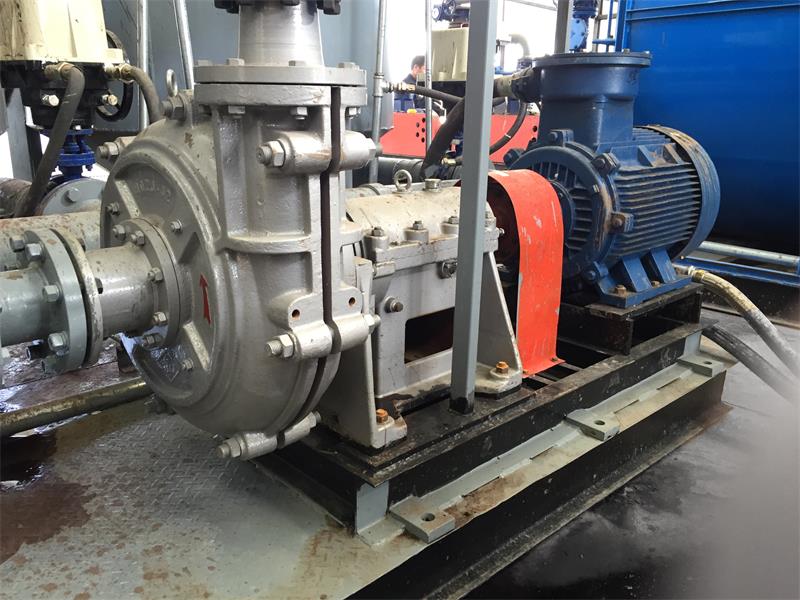

7.1 Horizontal Centrifugal Slurry Pumps (The Most Widely Used Type)

● These are your standard models that are installed on the ground

● By far the most common type you'll see out in the field

● Flexible power options - hook them up to electric motors or diesel engines

● Great for general industrial use where you've got space and need reliability

● Easy to access for maintenance (which you'll appreciate when service time comes)

7.2 Vertical Slurry Pumps (Also Known As Submerged Slurry Pump)

● Designed for those tricky "half-and-half" situations

● Pump casing takes a dive underwater while the motor stays high and dry

● Perfect for sumps, pits, and pools where space is tight

● Saves you floor space since it's mounted vertically

● Just make sure the pump casing is properly submerged or there will be problems

7.3 Submersible Slurry Pumps (Also Known As Submersible Sewage Pump)

● These submersible type of pumps operate completely underwater – both pump and motor

● No complicated mounting structures needed - just drop it in and get started

● Super simple installation (plug and play, basically)

● Ideal for dredging or any application where the pump needs to be right in the thick of things

● Built tough to handle complete immersion in the nastiest slurries

When deciding which type to go with, you'll want to think about:

● Pressure needs: How much discharge pressure is required?

● Flow rates: How many cubic meters per hour are going to be handled?

● Solids handling: What size of the solids/particles are?

● Maintenance: How easy does it need to be to service?

● Budget: Different brands and different origin of slurry pumps?

Each slurry pump type has its advantages - horizontal type for general duty, vertical type for limited space, and submersible type for sumps. The good news is: there's almost always a pump configuration that will match your specific needs if you know what exactly your requirements are.

Advice: Don't simply focus on the upfront slurry pump prices - think about long-term maintenance and operating costs too. Sometimes spending a bit more initially would save a lot in the future. And when in doubt, contact our engineers who can point you in the right direction.

Let's make a summary of those slurry pumping devices with the key features. Slurry pumps are purpose-built machines designed specifically to handle the toughest pumping jobs out there -abrasive mixtures that would destroy regular pumps rapidly. The heavy-duty construction of such centrifugal slurry pumps is what sets them apart, with reinforced components that stand up to tough conditions day after day.

Throughout this guide, we've broken down everything you need to know:

● The different pump types available (horizontal, vertical, and submersible models)

● All the critical components that make up these rugged machines

● Exactly how they operate to move difficult slurries

● The wide range of industries that rely on them

● The crucial factors to consider when selecting one

Getting the right slurry pump specification absolutely matters - it's the difference between equipment that lasts for years versus constant breakdowns and replacements. That's why working with experienced slurry pump manufacturers and suppliers in China matters a lot. They bring specialized knowledge, custom engineering solutions, and ongoing support to the table.

Now that you've got this foundation of knowledge, you're in a much better position to choose the right slurry pumping solution for your specific needs. But remember – you are always welcome to contact us for any further questions or doubts regarding those slurry pumps.