Learn - Oct. 20, 2023

Polypropylene is an important branch industry in petrochemical industry.

Polypropylene which is produced from propylene as raw material, is one of the common synthetic resins in the world.

Polypropylene produced from propylene as raw material. Petroleum makes polypropylene, accounting for more than 60 percent of polypropylene production capacity, and the second is coal makes polypropylene, accounting for 26 percent of polypropylene production capacity.

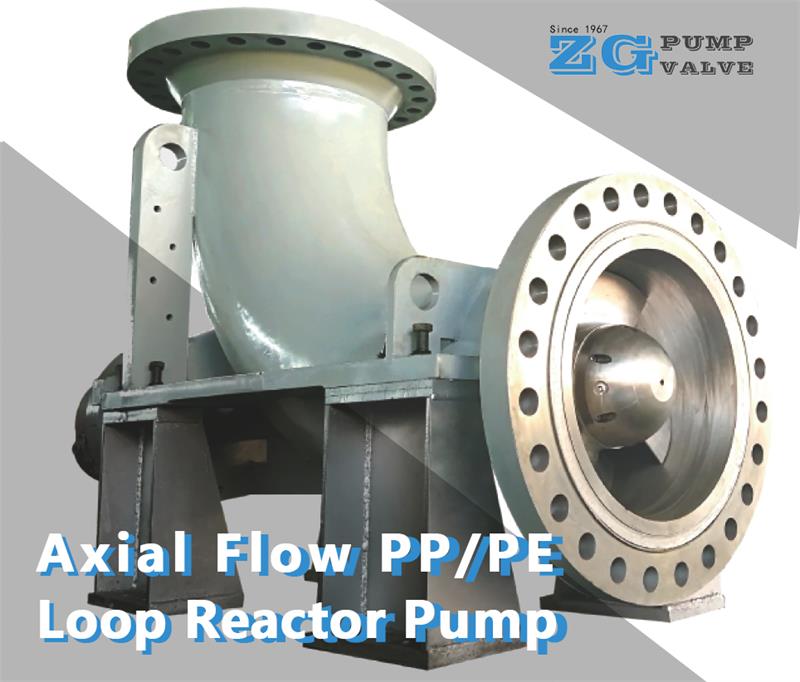

Therefore, the polypropylene manufacturing process is very critical. What's more, the axial flow polypropylene loop reactor pump is the key equipment of polypropylene production plant, which provides the cyclic reaction power for the polypropylene plant and plays the role of mixing. An axial flow polypropylene loop reactor pump is also known as an axial flow Polyolefin loop Reactor circulation Pump, annular axial flow pump, and High Pressure circulation pump in loop reactor.

A polyolefin is any of a class of polymers produced from a simple olefin (also called an alkene with the general formula CnH2n) as a monomer. For example, polyethylene is the polyolefin produced by polymerizing the olefin ethylene. Polypropylene is another common polyolefin which is made from the olefin propylene.

Axial flow Polyolefin loop reactor pumps feature Seamless forging high pressure elbow casing, which circulate the raw slurry medium in the reactor, and have the advantages of good heat transfer effect, high capacity, high temperature resistant and high pressure resistant, medium to high speed operation. This High Pressure Axial Flow Polyolefin Loop Reactor Pumps are designed for the circulating of polyethylene (PE) and polypropylene (PP) slurry medium, and other flammable and explosive medium.

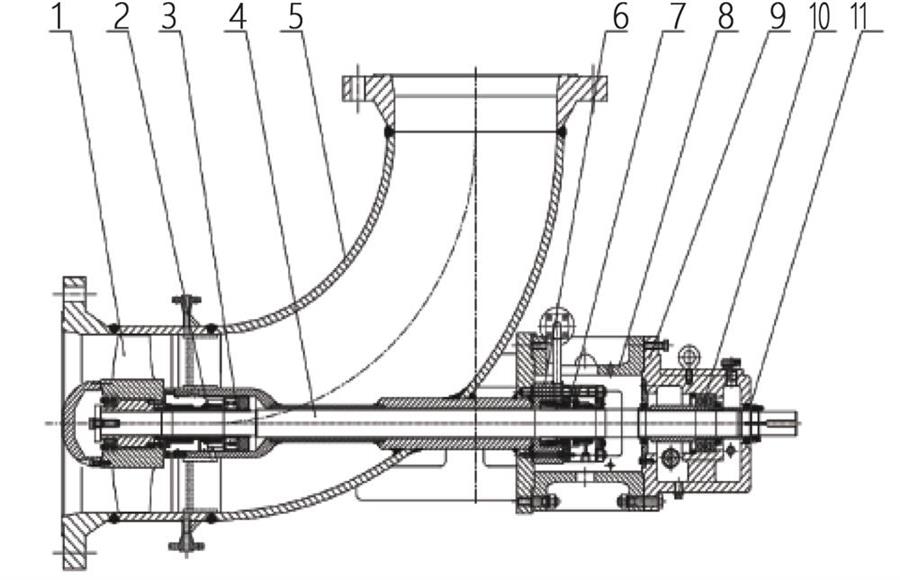

| 1. Impeller | 2. Primary mechanical seal |

| 3. Inner bearing | 4. Shaft |

| 5. Seamless forging elbow casing | 6. Safety mechanical seal housing |

| 7. Safety mechanical seal | 8. Connector |

| 9. Bearing housing | 10. Bearing |

| 11. Oil seal |

Main design features

1. High-pressure Seamless forging Elbow Casing is designed and tested to API standard, ASME Boiler and Pressure Vessel Code.

2. Triple mechanical Seal Arrangement is standard on high pressure and hazardous loop reactor axial flow pumps, providing added safety and increased reliability over alternative designs.

3. Seamless forging high pressure elbow casing is complied with ASME Boiler and Pressure Vessel Code.

4. Complying with API Plan 32/53C/52 seal arrangements and support systems ensure adequate seal face lubrication and cooling for proper operation.

5. Direct mounted or with sprung baseplate to accommodate thermal expansion of loop reactor vessel.

6. Hand polished impeller and elbow passageways ensures the flow path is smooth inside of the pump.

Main applications

Polyolefins industry

Slurry phase polypropylene (PP)

Slurry phase polyethylene (PE)

The high pressure axial flow PP/PE reactor pump is specifically for loop reactor circulation system, which could meet requirements of polyolefin plants.

We have continuously refined and tested high pressure loop reactor circulation pumps’ designs, and which become the preferred pump for polyolefin production plants with competitive price in recent years.