Learn - Nov. 20, 2023

We human beings can not live without oil, which is the gift of earth to human beings in the industrial age. Every day, oil drilling projects are being carried out almost everywhere in the world. The complex and diverse geological structure of the earth determines the awfully different oil storage conditions in different regions, and the oil recovery gain rate is extremely different in different regions. The technology in countries like the United States, South America and China is totally different from the technology in the Middle East. For areas with a small reserve-production ratio, oil recovery requires the use of Enhanced Oil Recovery technology, shorted as EOR.

Petroleum Industry

EOR : By injecting fluids that mix with crude oil, such as chemicals, surfactants, thermal medium, etc., properties of physical and chemical change and lead to occur at the interface of oil, water and rock, and the purpose of oil recovery gain rate could be improved.

In EOR, one of an important methods is polymer oil driven processing, in which polymers are injected to drive crude oil. The polymer oil driven processing refers to the addition of polymers in injected water to reduce oil flow ratio, expand sweep volume, and achieve to improve oil recovery gain rate.

A Polymer injection reciprocating plunger pumps is a kind of major fluids equipment for polymer oil driven processing in EOR. It is also known as a three-column polymer injection pump, or a three-cylinder reciprocating plunger pump.

Three-column polymer injection pumps are used widely on ground in fields. The role of polymer injection pumps is to pressurize polyacrylamide mother liquids and then inject them into the formation with high pressure sewage. First, the polymer is mixed with water, stirred and matured to obtain the polymer mother liquids, and then the mother liquids are pumped into polymer injection pumps by screw pumps, and finally the polymer injection pumps are pressurized and mixed with high pressure sewage or water according to a specific proportion before injection into the wellheads.

The performance requirements of Petroleum Industry for polymer injection pumps are: the mechanical shear force of the polymer liquid tends to minimize, and the viscosity retention ratio of the polymer liquid tends to maximize in the process of being injected by the polymer plunger pump.

The polymer reciprocation plunger pump, to meet the high pressure injection of viscous fluid, the output pressure is between 13Mpa-20Mpa, to avoid mechanical shear force, to meet the requirements of continuous injection on site with high reliability.

The medium transported by the polymer reciprocation plunger pump is the polyacrylamide mother liquor, the medium concentration is about 400-500mg/L, and the viscosity is about 200-300mP.s. We determined that an excellent polymer reciprocation plunger pump has the performance of high viscosity retention for the medium. The viscosity degradation of polymer mother liquor by polymer injection pump is as small as possible.

1. Optimize the flow channel design, reduce the mechanical shear rate, improve the suction performance of the plunger pump, and avoid the phenomenon of medium "drawing";

2. A variety of materials optional, carbon steel, austenitic stainless steel SS304, duplex stainless steel SS316/SS316L/2205/2507,according to the properties of medium select properly pump materials, to avoid suffer from chemical corrosion;

3. The viscosity degradation of polymer mother liquor by polymer injection pump is less than 3%.

1. Viscosity retention ratio of the polymer liquid is large;

2. The polymer injection pump is stable, safe and reliable in continuous operation;

3. The service life of the quick-wear parts is much longer than expected;

4. The stainless steel SS304 polymer injection pump, especially the application of duplex stainless steel SS316/SS316L/2205/2507 polymer injection pump is used in offshore oil, which has premium corrosion resistance and long lifetime.

In order to achieve greater oil recovery gain rates, petroleum engineers are constantly innovating and upgrading in the EOR, discovering new technologies and formulations. There is not only polymer oil driven processing, but also binary compound oil driven processing and heterogeneous compound oil driven processing. Heterogeneous compound oil driven processing family, including B-PPG displacing agent, polymer, surfactant. B-PPG displacement agent has excellent viscoelastic properties and migration properties, which could block large channels and extend the sweep range in the reservoir. Surfactants act like laundry detergent, washing more oil off the rock so as to increase oil recovery gain rates.

For example, some highly permeable reservoirs are in the high or ultra-high water containing stage and cannot rely on water oil driven processing, what’s more, the properties of high temperature, high salt, high calcium and magnesium in oil field restrict the application of polymer oil driven processing. The use of heterogeneous compound oil driven processing could achieve the purpose of regulating the flow field, spreading the spread and improving the efficiency of oil washing, and the performance of high temperature resistance and salt corrosion resistance is also very excellent. We know that the features of the reciprocating plunger pump are: the flow rate of the pump depends only on the working chamber volume change value and change frequency, and has nothing to do with the discharge pressure. Therefore, changes in the physical and chemical properties of the polymer medium do not affect the pumping equipment. Three-column reciprocating plunger pumps have wide range of applications, and heterogeneous compound oil driven processing also uses polymer injection pumps.

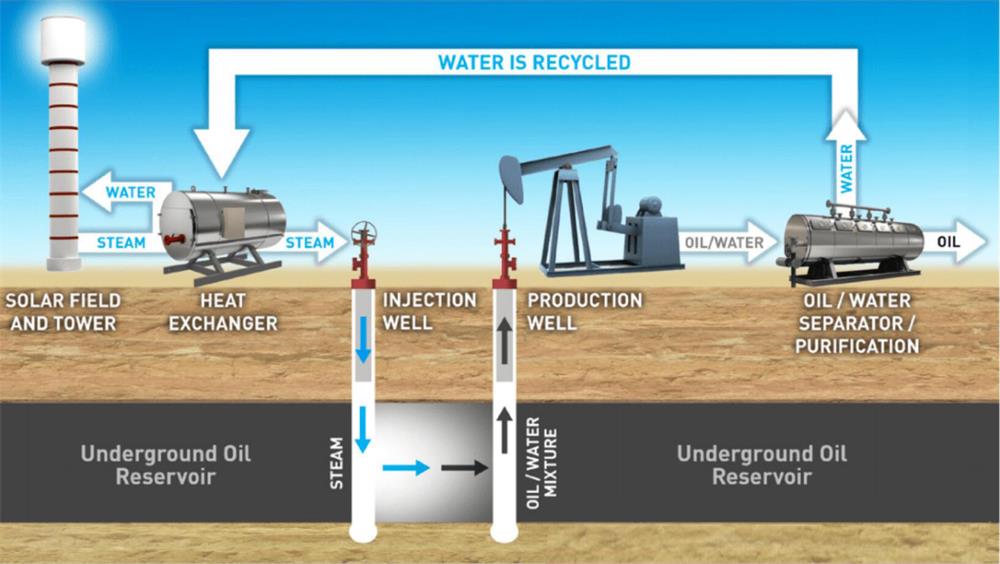

A large-scale oil field is a comprehensive energy industry project. Renewable energy makes contributions for oil production industry. In inland oil fields, solar-thermal power stations are equipped near by. In offshore oil fields, tidal or wind power stations are equipped. We have been committed to the construction of clean energy, green sustainable, low-carbon and high-quality oil recovery projects. Also believe that in the future, there will be more and more new integrated energy companies that are clean, low-carbon, renewable, safe and efficient, and multi-energy complementary.