■Flow rate: Q=0.2~84.9 m3/h

■Max. discharge pressure: 80 Mpa

■Max. temperature: 140℃

■Rated bhp: 290 - 1020HP

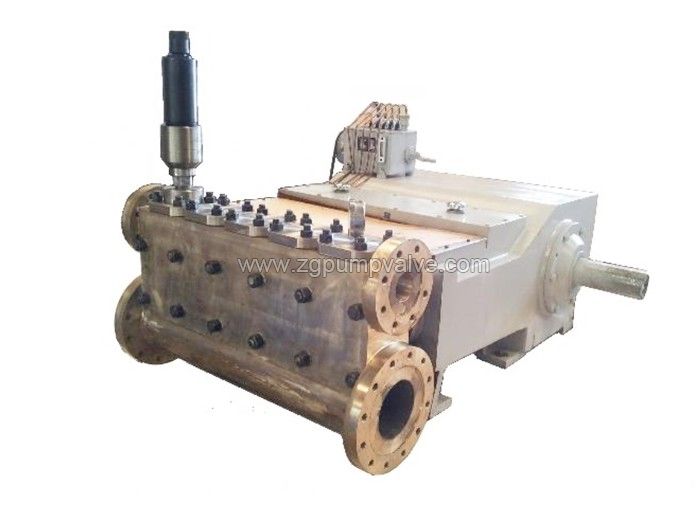

1. The hydraulic end of the five-plunger pump adopts a horizontal straight-through combination valve and an integral pump head structure.

2. The plunger pump relies on the change of the working volume of the seal to achieve the effect of absorbing pressure fluid, so as to achieve the conversion of mechanical energy into liquid pressure energy. Compared with other types of pumps, the plunger pump has the advantages of good sealing, small leakage and large power to mass ratio.

3. The reciprocating plunger pump uses the reciprocating movement of the plunger in the working chamber of the cylinder to periodically change the volume of the working chamber.

4. Structurally, the working chamber of the reciprocating plunger pump is separated from the outside by means of a sealing device, and is connected or closed with the pipeline through the pump valve (suction valve and discharge valve).

Reciprocating plunger pump is mainly composed of a plunger pump body, flow distribution system and driving mechanism, it through the plunger in the pump body for reciprocating movement of the plunger, so that the pump body and the top of the plunger to form a variable working volume, the rotating motion of the prime mover through the driving mechanism to make the plunger reciprocating movement, at the same time, the flow distribution mechanism under the position constraint mechanism, When the working volume of the plunger pump is enlarged, the pump chamber is connected with the oil suction chamber, and when the working volume of the plunger pump is reduced, the pump chamber is connected with the oil discharge chamber, and the hydraulic energy is transferred from the oil suction chamber to the oil discharge chamber.

Standard materials of construction for key components are provided below for material. Many options are available, particularly for fluid cylindervalves, stuffing box, packing, plungers, and O-ring seals, to meet the needs of special fluids, temperatures, and other requirements.

Fluid Cylinder:1045 Carbon Steel with Nickel-Boron Coating / Stainless steel SS304 / Stainless steel SS316/ Stainless steel SS316L / Duplex Stainless Steel 2205 / Duplex Stainless Steel 2507 / Titanium / Titanium Alloy/Nickel / C955 Nickel Aluminum Bronze / Hastelloy

Stuffing Box : 420 Stainless Steel/ Stainless steel SS304 / Stainless steel SS316/ Stainless steel SS316L / Titanium / Titanium Alloy/Nickel / Hastelloy

Adjusting Nut : Aluminum Bronze

Throat Bushing: Aluminum Bronze

Packing Follower Ring : Aluminum Bronze

Lantern Gland :Aluminum Bronze (if applicable)

Top Cover : 420 Stainless Steel/ Stainless steel SS304 / Stainless steel SS316/ Stainless steel SS316L / Titanium / Titanium Alloy/Nickel / Hastelloy

Front Cover :420 Stainless Steel / Stainless steel SS304 / Stainless steel SS316/ Stainless steel SS316L / Titanium / Titanium Alloy/Nickel / Hastelloy (if applicable)

Plunger : Tungsten-Carbide on Steel Base

Fluid End Studs :Alloy Steel, Nickel-Boron Coated

Fluid End Nuts : Alloy Steel, Nickel-Boron Coated

O-Rings :HNBR Rubber

Packing :Braided Teflon-Kevlar

Valve Assembly1 :17-4 Stainless Steel SS304 / Stainless steel SS316/ Stainless steel SS316L / Titanium / Titanium Alloy/Nickel / Hastelloy

| Item | Factory standard | Optional configurations |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Gear box |  | Reputed China brand | SEW, Shandong Chenghua, Zhengzhou machinery instituteSiemens, Flender |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

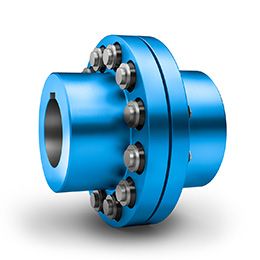

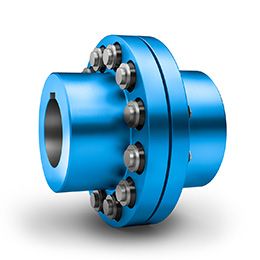

| Couplings |  | Pin type | Flexible diaphragm coupling |

| Diesel Engine |  | Reputed China brands | Cummins, Deutz, or designated brands |

The reciprocating five-plunger pump is used for various types of equipment powered by hydraulic pressure, which is not only used for oil field water injection and large displacement sewage reinjection, coal mine water injection, well washing, but also as the ground pump of hydraulic piston pump for oil production, the feed pump of thermal recovery boiler, and the injection of microbial solution pump.

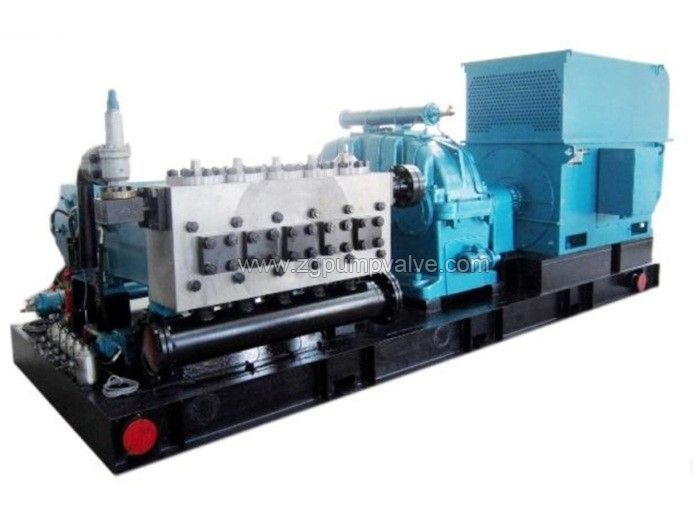

In order to meet the requirements of the oilfield, as the necessary equipment for the sewage reinjection on the oilfield, we designed and produced a reciprocating five-plunger waterflooding pump unit for the oilfield reinjection, which is composed of a plunger pump, a filtration system, a dosing system, a power distribution system, a water distribution system, a skid-mounted system, etc., and can also be configured with a diesel engine to achieve mobility and far-sight control.

Energy, oil and natural gas, LNG project

Chemical industrial

Mining

Pulp and paper,

Food

Medical

Steel, aluminum,

Reverse osmosis,

Detergents

High pressure scale washing