Chlor-alkali industry

Application of high temperature alkali pumps in chlor-alkali industry

High temperature alkali pumps made from nickel are used to transport alkaline, viscous medium with small flow rates and temperatures up to 160 degrees.

Pump type: High temperature alkali pump

Pump characteristics: small flow rate, high head, strong corrosive medium

Flow parts material: nickel

Pump parameters:

● Flow rate: 4 m3/h

● Head: 47 m

Working parameters:

Transport 48% NaOH molten alkali, medium temperature is 160℃, viscosity is 4.40cP (1cP=0.001Pa·s)

Analysis:

1. The material of alkali pumps’ flow parts were chosen as nickel to meet the requirements of high corrosion resistance. Nickel is recognized as one of the most corrosion-resistant metals.

2. The temperature of medium is high. The pump structure adopts the middle support structure, the center line support structure, OH2 structure form centerline mounted support OH2 pump.

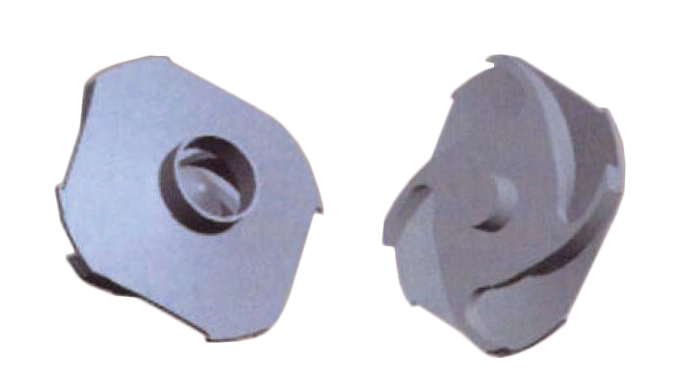

3. High temperature alkali pumps adopt back open double "S" shape square front cover plate impeller.

Impeller characteristics:

①The impeller is designed as an open-back structure, the number of blades is four, and the impeller is composed of two "S" shaped blades from the overall appearance.

②The rear cover plate is designed to be back open, straight streamline, simple processing technology, and convenient adjustment of axial clearance.

③Because there is no part of the front and back cover plates, the double "S" impeller is more suitable for the medium with certain viscosity, or the working conditions that are easy to crystallize or contain a small number of particles in the specific working conditions than the closed impeller.

④The number of double "S" impeller blades is small, which is conducive to the smooth flow channel, thereby improving the passing capacity of the medium, and has good fluidity when transporting the medium with high viscosity, easy crystallization or containing a small amount of particles.

Feedback

High temperature alkali pumps made from nickel have been operating stably for one year in the chlor-alkali plant. The flow rate and head meet the working condition requirements, and the flow parts are not corroded, and performance of mechanical seals is good, no leakage. The flow - lift curves of double "S" impeller alkali pumps are stable, no hump, are the ideal alkali pumps for conveying small flow, high temperature, strong corrosion and viscous medium.