QA&QC

The company has a complete quality assurance system, in strict accordance with the requirements of the "Quality Management System Requirements", has developed the "Quality Manual" and the corresponding documents, and continue to carry out quality system audit. The company's product performance testing procedures and equipment are perfect, each part has a full-time inspector, from model, blank manufacturing to parts processing, testing, assembly, performance testing, packaging and storage, factory delivery, every step, there are specifications management. In July 1999, the company passed the ISO 9001:2008 quality management system certification, passed the CE certification in 2017, and has the "National Industrial Product Production License", "Mineral Product Safety Sign Certificate" and large thermal power, oil, coal, steel, etc. Market access qualification for large industrial enterprises.

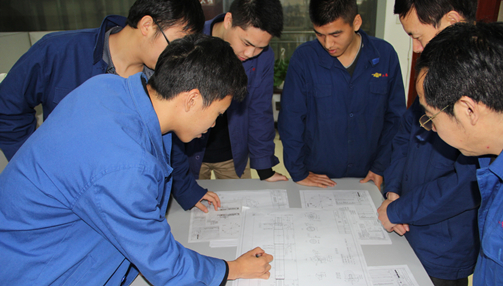

Step 1

Design and development review

Step 2

Raw material incoming inspection

Step 3

Process inspection of casting blanks

Step 4

Parts metal processing inspection

Step 5

Impeller dynamic and static balance test

Step 6

Pump body mechanical seal anti-leakage static pressure test

Step 7

Comprehensive performance parameter test of the whole machine