■Flow rate: Q=0.1~336 (m³/h)

■Flow per 100 Rotation(L): 3~200

■Suggestion Rotation Speed(rpm): 200/400/500

■Max. Viscosity: 1~1000000 cp

■ The cam cam is conjugated and has synchronous gear transmission. The cam mesh has no sliding wear and has a long service life.

■ Relying on the volume of space between the rotor and the pump chamber to produce a fixed delivery displacement, the impact on the volumetric efficiency of the pump is small when the outlet head changes, so the delivery flow is always stable as long as the bearing power and sealing capacity allow.

■ It relies on the pumping principle of volume transfer, instead of relying on the liquid inertia moving head for infusion, and the rotor speed is low, the liquid flow head is small, although the pump volume is small, it can be transported by large diameter pipe, so not only the conveying pressure along the way The head loss is small, the lift is high, and the construction cost of the pipeline is greatly reduced.

■ Because the volumetric efficiency is not affected by the working pressure, the output flow is stable, and the pumps running side by side on the branch pipe network are basically linearly superimposed, and the pump characteristics are basically unaffected.

■ Because the output flow is proportional to the pump speed, regardless of the pipeline characteristics, even at a very low speed, a certain flow output can be maintained, so that the speed can be controlled for controlled quantitative delivery, which can be applied to the process of process.

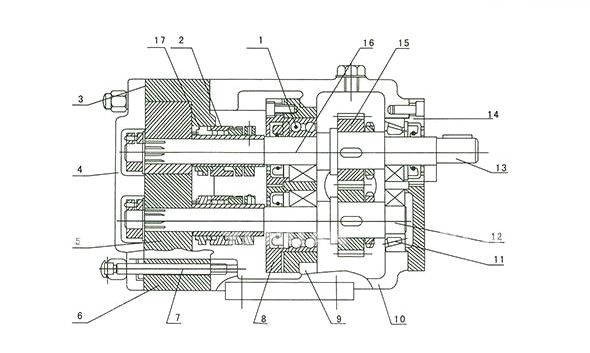

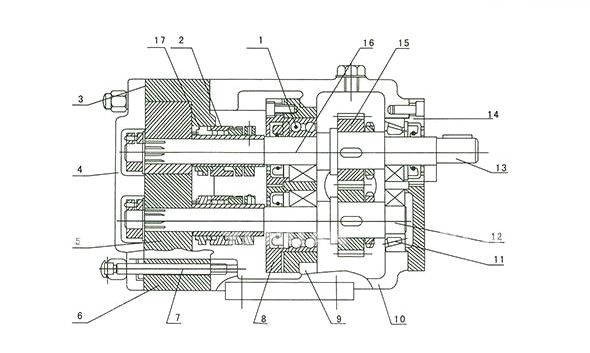

1. Two-row ball bearing

2. Mechanical seal

3. O ring seals

4. Pump cover

5. Three-bladed pump wheel

6. Pump casing |

7. Stud

8. Bearing gland

9. Bearing bracket

10. Gear box

11. Tapered roller bearing

12. Transmission shaft |

13. Line shaft

14. Gear box gland

15. Bevel wheel(a pair)

16. Oil seal

17. O ring seals |

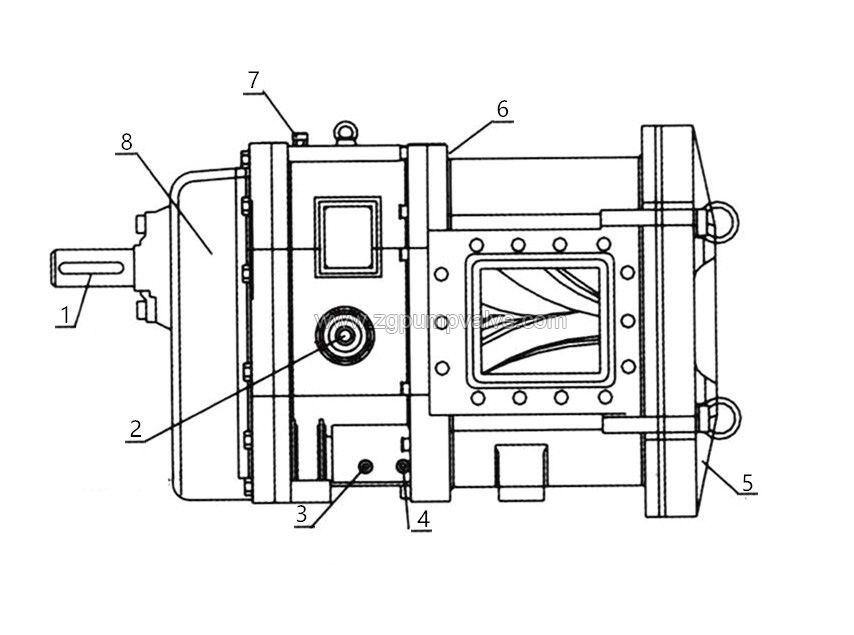

YZB rotary piston pump with reduction gearbox

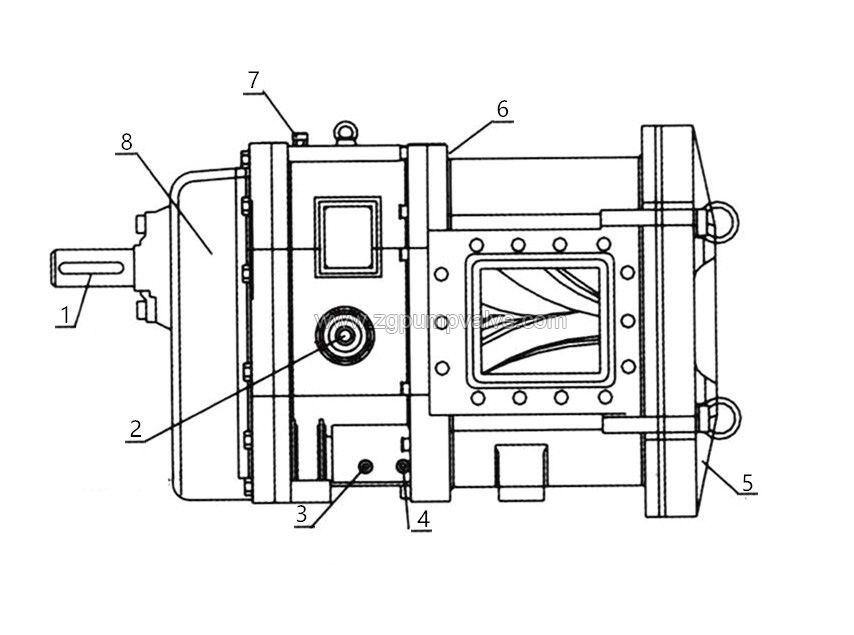

1. The drive shaft

2. Oil observation hole

3. Gear oil chamber

4. Among the oil hole Isolation cavity |

5. Fast and pump cover

*6. Among the oil hole cavity charging isolation

7. Synchronous breathing hole

8. Reducer |

|

*Keep open, prohibit jam |

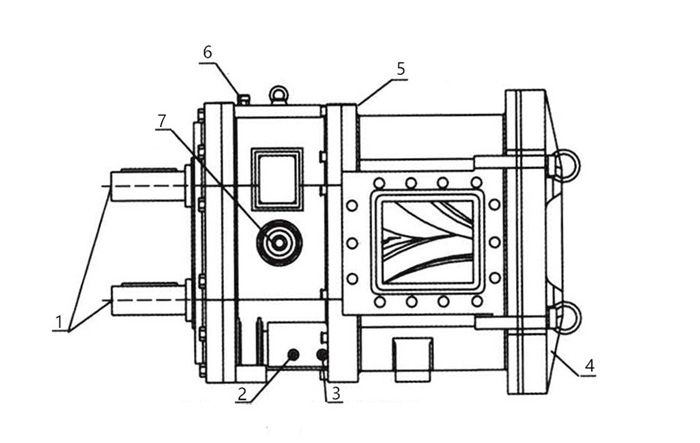

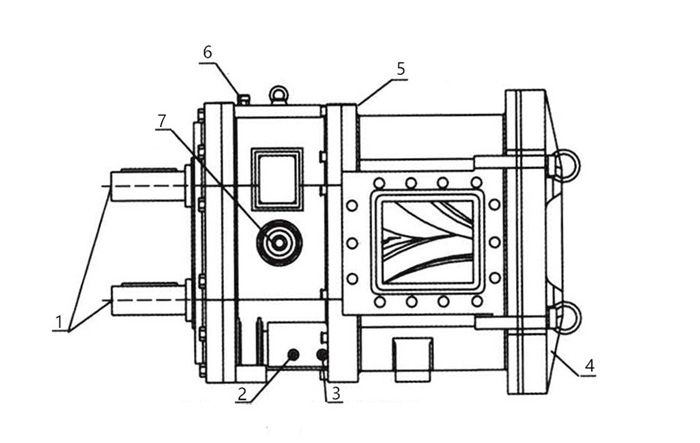

YZB rotary piston pump without reduction gearbox

1. The drive shaft

2. Gear oil chamber

3. Among the oil hole isolation cavity

4. Fast and pump cover |

*5. Among the oil hole cavity charging isolation

6. Synchronous gearbox breathing hole

7. Oil observation |

|

*Keep open, prohibit jam |

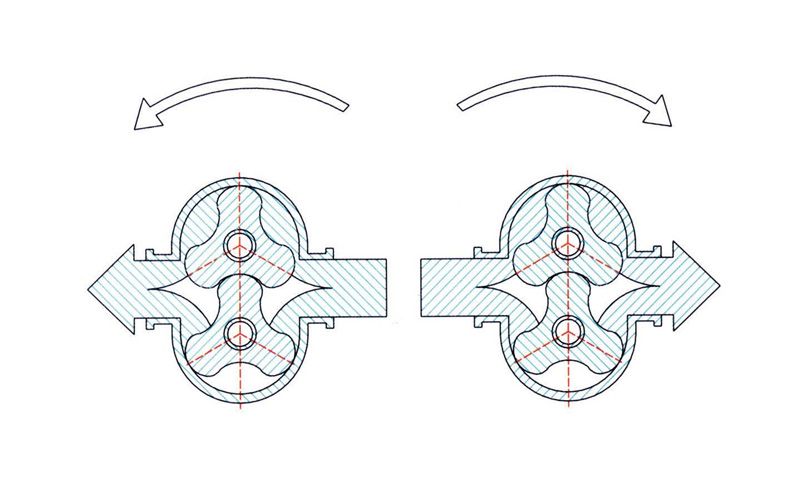

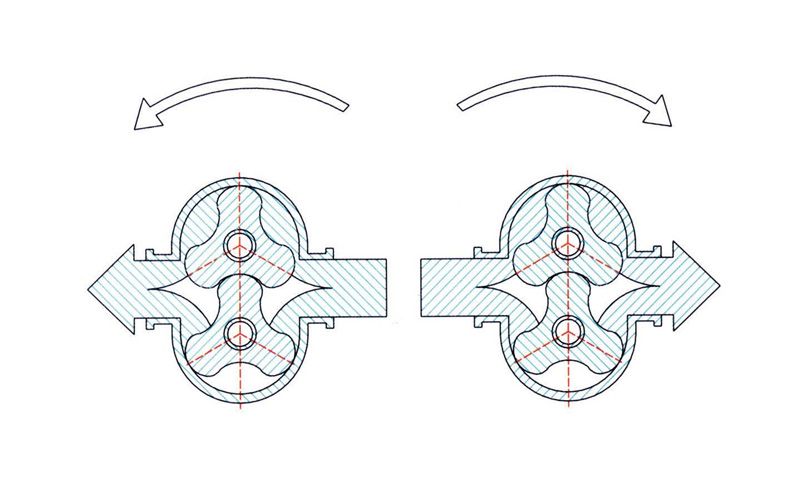

YZB rotary piston pump can be able to rotate in all directions. Please make sure that the pump rotate direction

according to the requirement .

|

Flexible coupling rotating anticlockwise

the flow direction of the medium |

Flexible coupling rotating clockwise

the flow direction of the medium |

■ Pump casing: CI, CS, SS304, SS316, SS316L, 2205, 2507.

■ Rotor: SS304, SS316, SS316L, 2205, 2507, brass, CS, NR-SBR, NBR, H-NBR, FPM/FKM, EPDM, PUR.

■ Environmental protection and treatment: sewage, municipal or industrial sewage treatment plant sludge, concentrated sludge, dosing pump, dewatering machine feed, flue gas desulfurization lime slurry, fertilizer solution, water and oil mixture and industrial waste mixture discharge.

■ Fire protection: transport fire water, foam water slurry, etc.

■ Petrochemical: transporting sludge, heavy oil, heavy oil, asphalt, coal water slurry, chemical fiber slurry, gasoline, diesel, kerosene, aviation kerosene, lubricating oil, various catalysts and various solid-liquid-gas multiphase mixtures Pulp and so on.

■ Daily chemical industry: transport various alcohols, lipids, glycerin, facial cleanser, shampoo, shower gel, skin cream, toothpaste, soap, detergent powder and so on.

■ Building materials, mining: transporting mine silt, cement slurry, drilling waste liquid, lime slurry, gypsum mud, etc., conveying various flotation pulp and tailings slurry before concentration.

■ Ship: Transporting ship sewage, seepage fluid, etc.

■ Agriculture: transport liquid fertilizer, animal food, waste food, biogas tank, etc.

■ Fine chemicals: transport dyes, pigments, various intermediates, chemical additives, printing and dyeing auxiliaries, silicone oils, adhesives, coatings, and various colloids, suspensions, etc.

■ Medicine, food industry: transport ointment, pill paste, lotion, puree, crushed fruits and vegetables, chocolate, syrup, honey, jam, condensed milk, dairy products, yeast mud, meat pulp, distiller's grains, and various fermentation and wet abrasive slurry Wait.

■ Paper industry: conveying pulp, adhesives, coatings, mineral powder fillers, etc.

■ Building materials ceramic industry: transporting various glazes, mineral mud mud, etc.