Screw Pump

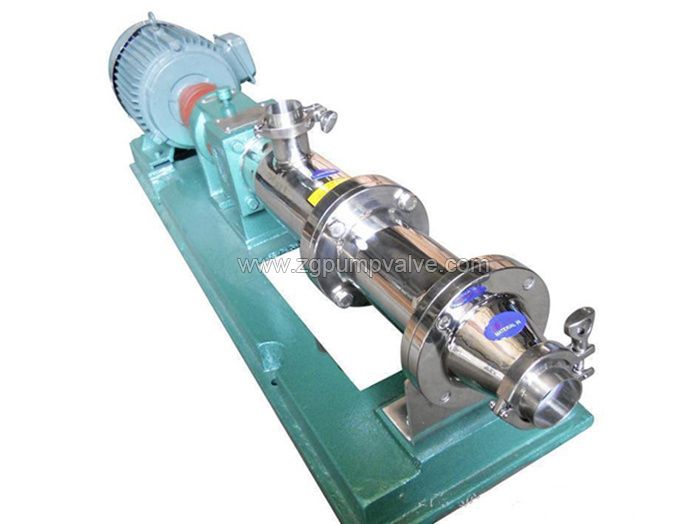

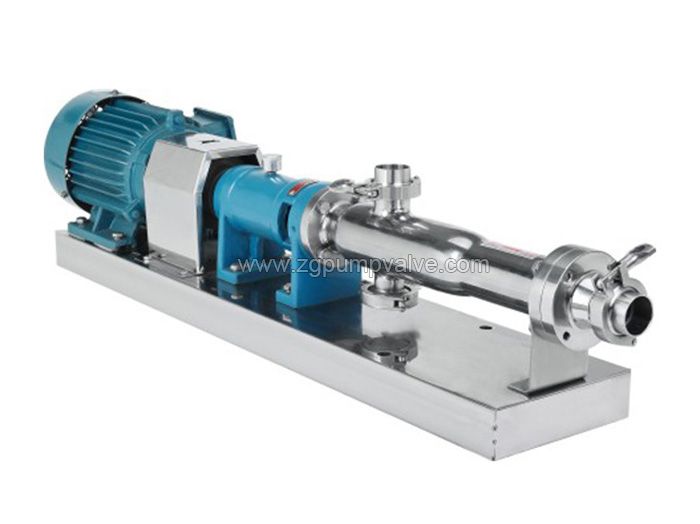

Sanitary screw pump

GS type sanitary screw pump(also known as progressive cavity pumps) is a displacement pump, which can be used to transport neutral or corrosive liquids, clean or abrasive liquids, gas or bubbles-producing liquids, high viscosity or low viscosity liquids, including A liquid containing fibrous matter and solid matter. It can work for a long time and maintain a smooth flow, with good self-priming ability.There are various materials available for our sanitary screw pump, including stainless steel SS304, SS316, SS316L,,duplex stainless steel.

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

■Flow rate: Q=0.8~150m3/h

■Pressure: H=0.6~55 Mpa

■Speed: n=400rpm/630rpm/720rpm/960rpm

■Particle diameter: <150 mm

■Both ends of the connecting shaft adopt a one-word or refined universal joint, and the pin and the pin sleeve are made of special materials, so the life of the joint is greatly improved, and the structure is simple and easy to disassemble.

■The type of liquid viscosity range, can be customized according to the needs of the stepless speed regulation, electromagnetic speed regulation

■A replaceable stuffing box is installed between the suction pipe and the bearing, which can be used for packing sealing and mechanical sealing (sealing replacement can be carried out in different forms).

■Sanitary standard, all stainless steel polishing treatment, can be customized cart funnel

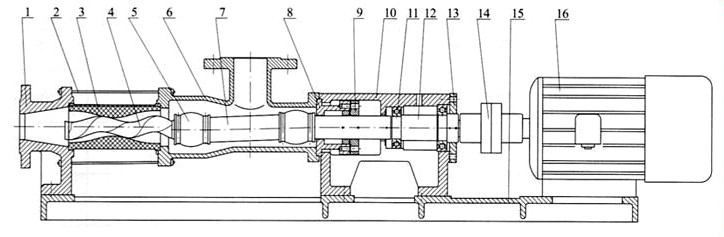

1. Discharge casing 2. Connection rod 3. Stator 4. Screw shaft 5. Universal joint | 6. Suction chamber 7. Intermediate shaft 8. Seal cover 9. Axial seal components 10. Bearing housing | 11. Bearing 12. Transmission shaft 13. Bearing cover 14. Couplings 15. Bracket 16. Motor |

| No. | Description | Material | |||||

| Anti-corrosion alloy | Cast steel | Stainless steel | |||||

China standard | ASTM standard | China standard | ASTM standard | China standard | ASTM standard | ||

| 1 | Pump casing | 20# Alloy Titanium Nickel 904L Ti/Pd Alloy Monel | Hastelloy Monel Ⅱ-B Ⅱ-C Ni-Resist1 Ni-Resist2 Ni-Resist3 | 25# 35# | WCA WCB | ZG1Cr13 ZG2Cr13 ZG00Cr18Ni10 ZG0Cr18Ni9 ZG0Cr18Ni12Mo2Ti ZG0Cr17Ni4CuNb ZG1Cr18Ni9 ZG1Cr18Ni9Ti ZG00Cr17Ni14Mo2 0Cr26Ni5Mo2 0Cr17Mn13Mo2N 00Cr18Ni5Mo3Si2 | CA-15 CA-15M CF-3(304L) CF-8(304) CF-8M(316) CF-3M(316L) CN-7M(320) CD-4MCu |

| 2 | Stator | ||||||

| 3 | Rotor | ||||||

| 4 | Suction chambe | ||||||

| 5 | Intermediate shaft | Carbon steel SS420 2205 SS304 SS316 | |||||

| 6 | Bearing housing | Cast iron | |||||

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Mechanical seal |  | Zigong brand | Burgmann, Sihuan riji, Chengdu Yitong |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

■ Food industry: transporting meat, potato salad, paste paste, concentrated juice, jam, vegetable products.

■ Brewing industry: transporting distiller's grains, yeast, various residues after fermentation, and ingredients.

■ Sugar industry: syrup, saturated slag, concentrated wastewater slag, sugary crystal paste; milk, cheese.

■ Textile industry: conveying synthetic fiber liquid, viscose liquid, dye, ink, nylon powder liquid.

■ Paper industry: conveying pulp slurry, talc slurry, glazing resin slurry.

■ Petroleum industry: transporting a variety of oils, oil products, refinery sludge, industrial wastewater.

■ Chemical industry: various latex liquids, suspensions, ointments, shampoos, paints, pigments.

■ Construction industry: transporting mortar, plaster, asphalt, tar, silt, and paint.

■ Mining industry: transporting oxides and wastewater, mine drainage, liquids, and scum.

Company video

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

+86 28 8218 1182

-

+86 28 8218 1182