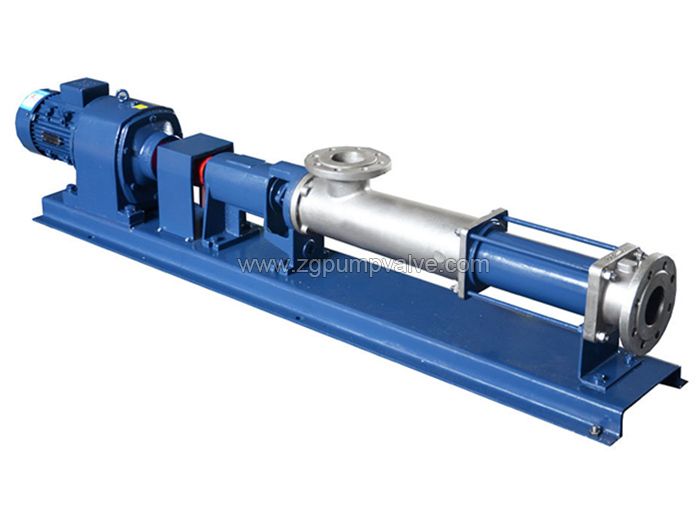

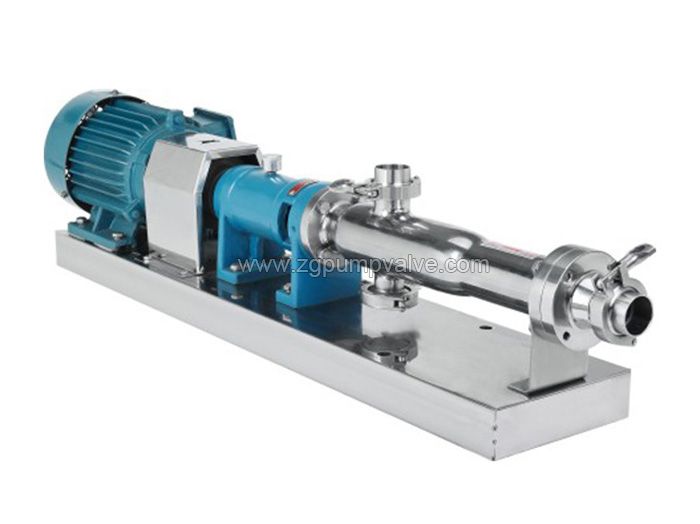

Screw Pump

Single screw pump

The biggest characteristic of single screw pumps(also known as progressive cavity pumps) is strong adaptability to medium, stable flow, small pressure pulsation, high self-priming capacity and pressure of 0.6~ 1.2MPa, which can meet the different needs of users for single screw pumps.There are various materials available for our single screw pump, including stainless steel SS304, SS316, SS316L, 904L, duplex stainless steel CD4MCu, 2205, 2507, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

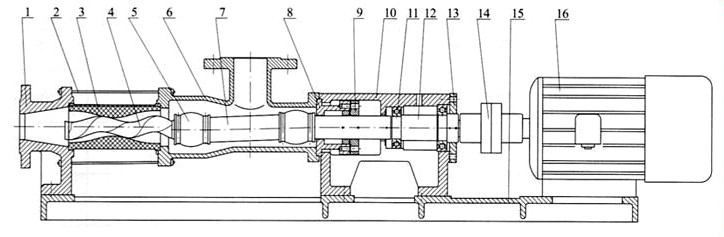

Structure

-

MOC

-

Configuration

-

Application

-

Performance

■Flow rate: Q=1~166m3/h

■Pressure: H=0.6/1.2 Mpa

■Speed: n=380rpm/720rpm/960rpm

■Temperature: T=-20~120℃

■The single-screw pump is a new type of pump that works on the principle of oscillating meshing volume. The main working parts are eccentric screw (rotor) and fixed bushing (stator). ■Due to the special geometry of the two components, a separate sealing cavity is formed, the medium is uniformly propelled by the axial direction, the internal flow velocity is low, the volume remains unchanged, and the pressure is stable, so that eddy current and agitation are not generated. The output pressure of each pump is 0.6MPa, the head is 60m (clear water), and the self-priming height is generally above 6m. The drive can be directly driven by a coupling or by a speed-regulating motor, a three-corner belt, a gearbox, etc. The pump has few parts, compact structure, small size and easy maintenance. The rotor and the stator are the wearing parts of the pump, and the structure is simple and easy to assemble and disassemble. Since the stator is made of a variety of elastic materials, the pump delivers high viscosity fluids and transports containing hard suspension particulate media or fiber media, which are not suitable for general pumping. The flow rate is proportional to the speed.

1. Discharge casing 2. Connection rod 3. Stator 4. Screw shaft 5. Universal joint | 6. Suction chamber 7. Intermediate shaft 8. Seal cover 9. Axial seal components 10. Bearing housing | 11. Bearing 12. Transmission shaft 13. Bearing cover 14. Couplings 15. Bracket 16. Motor |

| No. | Description | Material | |||||

| Anti-corrosion alloy | Cast steel | Stainless steel | |||||

China standard | ASTM standard | China standard | ASTM standard | China standard | ASTM standard | ||

| 1 | Pump casing | 20# Alloy Titanium Nickel 904L Ti/Pd Alloy Monel | Hastelloy Monel Ⅱ-B Ⅱ-C Ni-Resist1 Ni-Resist2 Ni-Resist3 | 25# 35# | WCA WCB | ZG1Cr13 ZG2Cr13 ZG00Cr18Ni10 ZG0Cr18Ni9 ZG0Cr18Ni12Mo2Ti ZG0Cr17Ni4CuNb ZG1Cr18Ni9 ZG1Cr18Ni9Ti ZG00Cr17Ni14Mo2 0Cr26Ni5Mo2 0Cr17Mn13Mo2N 00Cr18Ni5Mo3Si2 | CA-15 CA-15M CF-3(304L) CF-8(304) CF-8M(316) CF-3M(316L) CN-7M(320) CD-4MCu |

| 2 | Stator | ||||||

| 3 | Rotor | ||||||

| 4 | Suction chambe | ||||||

| 5 | Intermediate shaft | Carbon steel SS420 2205 SS304 SS316 | |||||

| 6 | Bearing housing | Cast iron | |||||

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Mechanical seal |  | Zigong brand | Burgmann, Sihuan riji, Chengdu Yitong |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

Generally speaking, the single-screw pump can be used as a general-purpose pump. The running speed of the pump can be high or low. The rated pressure of the outlet of the pump can be increased with the number of stages of the pump. For each additional stage, the pressure is increased by 0.6MPa. , so the scope of use is extremely wide.

■Environmental protection: the transportation of industrial sewage, domestic sewage, muddy water containing solid particles and short fibers. It is especially suitable for equipment such as oil-water separators and plate and frame filter presses.

■Shipbuilding industry: transportation of medium such as wheel bottom cleaning, oil water, oil residue, oil sewage, etc.

■Petroleum industry: transporting crude oil, in later oil fields, using a screw pump to inject polymer into the formation to increase oil recovery.

■Medicine, daily: a variety of thick paste, emulsion, a variety of ointment cosmetics and other transport.

■Food canning industry: a variety of viscous starch, cooking oil, honey, syrup, fruit pulp, butter, fish gizzard and its scraps.

■Brewing industry: all kinds of fermented viscous liquid, distiller's grains, grain products, slag, various sauces, pulp and the transportation of mucilage containing massive solids

■Construction industry: spraying and conveying of cement mortar, lime slurry, paint and other pastes.

■Mining industry: sewage, muddy water, etc. containing solid particles in the mine are discharged to the ground.

■Chemical industry: transportation of various suspensions, greases, various colloidal pulps, and various adhesives.

■Printing and paper industry: high viscosity ink, PVC polymer paste for wallpaper, pulp of various concentrations, short fiber slurry, etc.

Company video

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

+86 28 8218 1182

-

+86 28 8218 1182