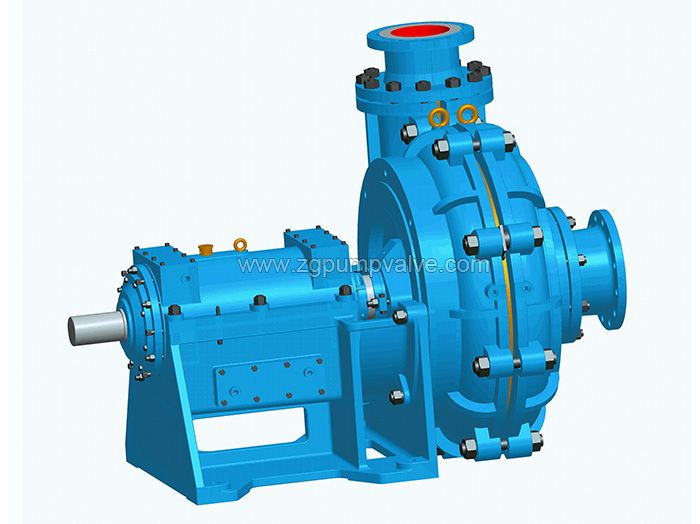

Slurry Pump

Long shaft submerged slurry pump

CL long shaft submerged pump is deriving product of CLWⅡ series, it was designed to meet the special requirements of long shaft submerged pump, like no stale clean water(for pump lubricating) at site, or only needs to pump clean water, and the cost problem.There are various materials available for our long shaft submerged pump, including cast iron, stainless steel SS304, SS316, SS316L, 904L, duplex stainless steel CD4MCu, 2205, 2507, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

■Flow rate: Q=140~9400 (m³/h)

■Total head: H=12~68 (m)

■Speed: n=585-1470rpm

■S.g.: γ ≤1.15

■Temperature: T=0~70℃

■Pump diameter: 150~1000mm

■Adopted advanced structure and hydraulic models to enable long life operation of high efficiency and stability.

■Compact structure takes smaller space,saving the construction cost.

■Standardized sectional length of pump shaft to meet different submerged depths, which is up to 25 m.

■Grease lubricated bearings can work properly even if the bearings are slightly soaked.

■Secondary impeller design to reduce the pressure, and there are holes on the impeller to balance the fluid pressure to ensure the sealing performance.

■Sectional combination structure enables the sectional maintenance to save the cost of operation.

■Guide vane type submerged pump,impeller is immersed in the fluid,the guide vanes in the middle section pushing the fluid all the way up along the main shaft.

■Impellers can multiply work in series,and the shafts and water guide pipes can be connected to enlarge the usage scale of pump.

■Shafts are connected by a special method with high precision to ensure the alignment and smooth operation of pump.

■The pump shafts are supported by roller bearings;the fluid is separated with shafts by the guard plates.

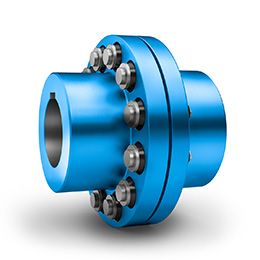

■Vertical installation with horizontal pump outlet; The rotary part is driven by the motor through the couplings.

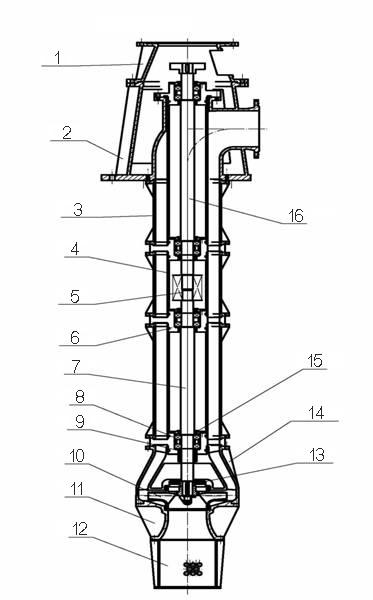

Structure drawing is as below

1. Motor seat 2. Pump support 3. Connecting pipe 4. Protective pipe 5. Coupling 6. Bearing seat | 7. Lower shaft 8. Bearing 9. Oil seal 10. Impeller 11. Pump cover 12. Filter | 13. Vice impeller 14. Spatial guide vane 15. Oil seal 16. Upper shaft |

■Pump cover and space guide vanes: ductile iron or steel castings

■ Impeller: cast steel or cast iron

■ bracket: gray cast iron

■Water conduit and protective tube: seamless steel pipe

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Mechanical seal |  | Zigong brand | Burgmann, Sihuan Riji, Chengdu Yitong |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

| Couplings |  | Pin type | Flexible diaphragm coupling |

■Suitable to pump clean water or fluids have close characters with water; The pumping temperature is below 80℃, solid diameter below 10 mm, fluid density below 15%.

■Sewage contains small quantity of particles.

-

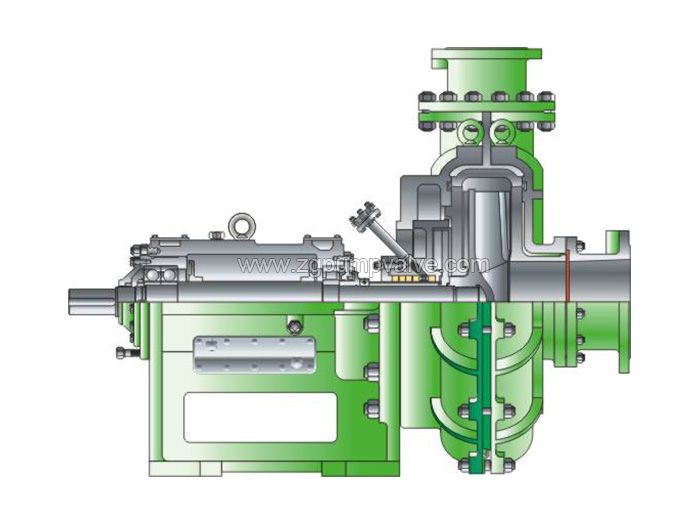

FGD flue gas desulfurization pump

Aiming at the characteristics of flue gas desulfurization project of thermal power plant

-

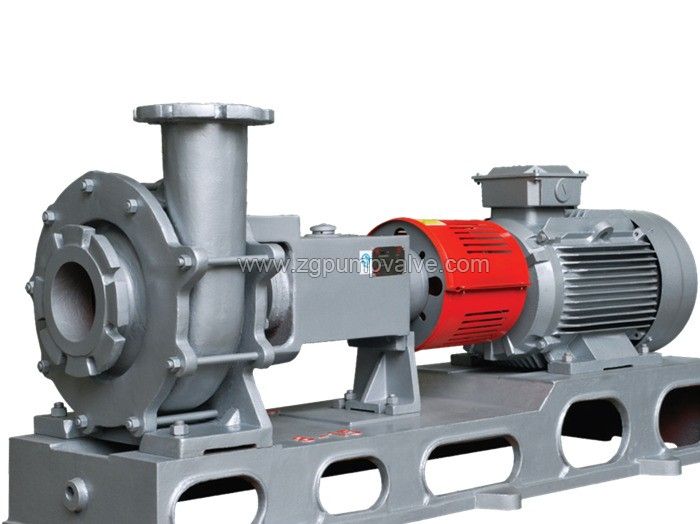

The ZP Series is a newly developed foam slurry pump with a unique impeller and blade design.

-

ZZ slurry pump is a research and development achievement for decades.

-

Single-layer casing slurry pump

The YMT slurry pump is an optimized design based on the theory of solid-liquid two-phase flow.

Company video

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

+86 28 8218 1182

-

+86 28 8218 1182