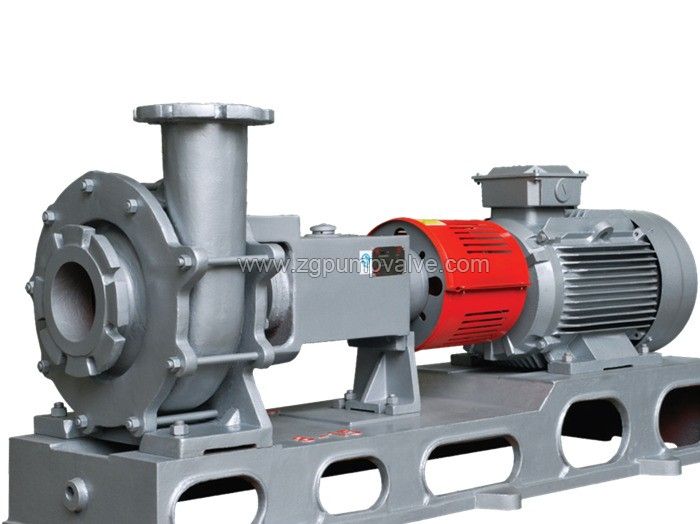

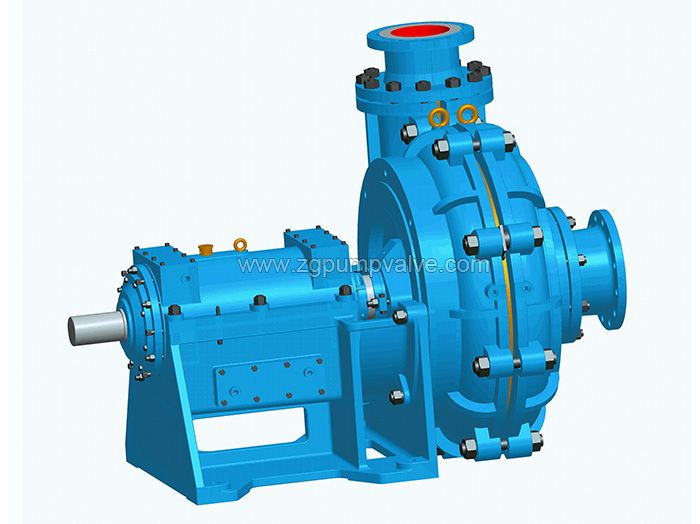

Slurry Pump

Double-layer slurry pump

ZZ slurry pump is a research and development achievement for decades. In 2009, it won the China Zigong Science and Technology Progress Award. The efficient design of solid-liquid two-phase flow is optimized. There are a variety of seal types, transfer methods and anti-wear materials for different applications. Suitable for pumping corrosive or abrasive slurries containing solids such as concentrates, tailings, coal ash, cinders, slurries, sediments... they can work in series if required.There are various materials available for our slurry pump, including stainless steel SS304, SS316, SS316L, duplex stainless steel, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

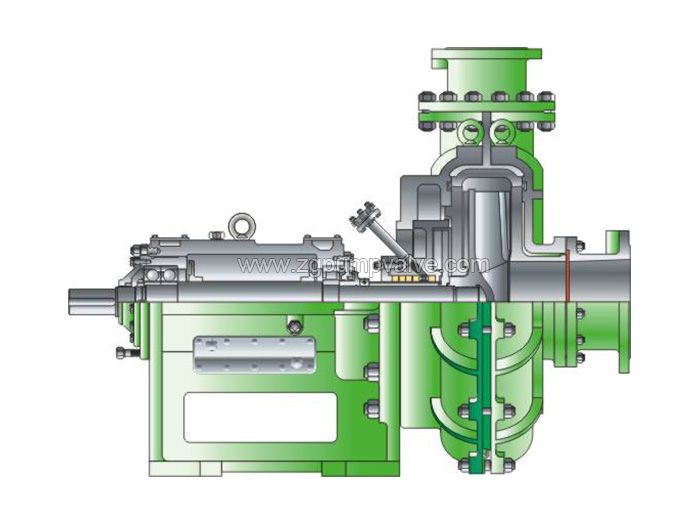

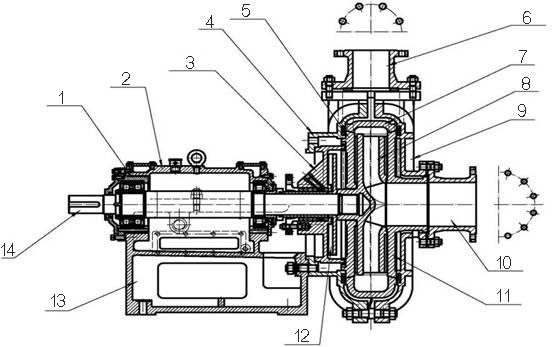

Structure

-

MOC

-

Configuration

-

Application

-

Performance

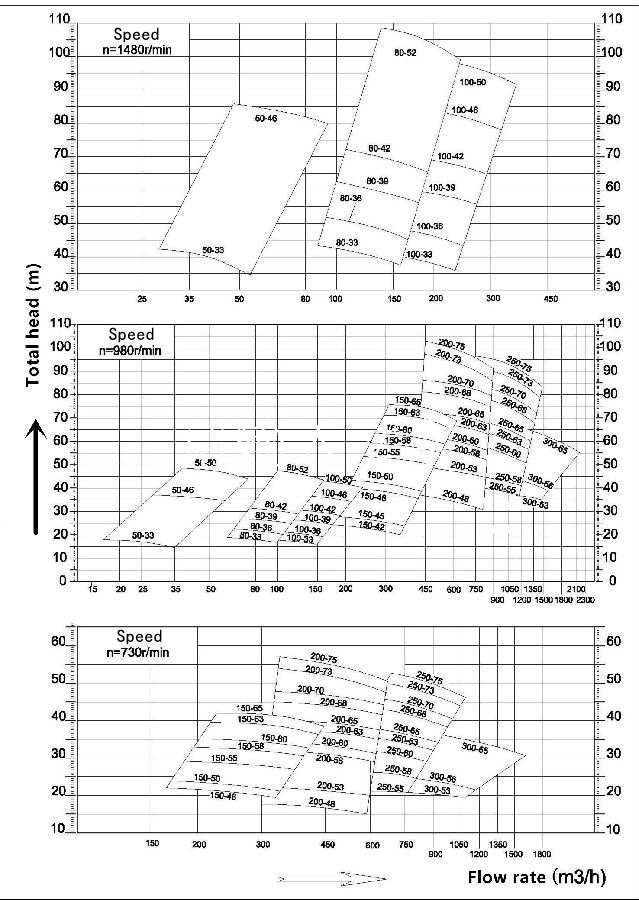

■Flow rate: Q=10~5000(m³/h)

■Total head: H=20~120 (m)

■Speed: n=490~2900rpm

■S.g.: γ ≤1.5

■Temperature: T=0~120℃

■Pump diameter: 50~450mm

■Optimized solid and liquid hydraulic model design of high efficiency and energy-saving.

■Thickened wetted parts design to improve the anti-abrasive ability and prolong pump life.

■Heavy duty shaft design,with better performance in strength.

■Reasonable bearing configuration and fully lubricated design ensures the long time and continuous operation.

■Suitable to pump corrosive or abrasive slurries contains solids,the mixture density of solids and liquid can be up to 60%.

■Various sealing types to meet different requirements.

■According to the requirements of clients,it can work in series.

■Axial split bracket and double layer casing structure.

■Outer casing is vertical split structure; pump outlet is able to be set on 8 different direction at 45° interval.

■Horizontal installation of big loading capacity.

■The jacket and guard plate as the lining,pump casing and pump cover is the frame.

■Shaft sealings: dynamic seal, packing seal and mechanical seal.

■Transmission: Direct coupled, V-belt drive, variable frequency drive, hydraulic coupling.

Structure drawing is as below

■Material of flow passage components based on pumped medium: Cr26 wear-resistant material, or Cr30, CD4MCu wear-resistant and anti-corrosion material, and other general wear-resistant material.

■Material of pump casing, pump cover, bracket etc. supporting parts: gray cast iron

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Mechanical seal |  | Zigong brand | Burgmann, Sihuan Riji, Chengdu Yitong |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

| Couplings |  | Pin type | Flexible diaphragm coupling |

■Mineral separation and tailings slurry conveying.

■Slurry conveying during the producing process of aluminum oxide.

■Conveying sewage contains solids in industries of thermal power, cement, steel, non-ferrous metal...

■Sewage and slurry conveying of other industries.

-

Single-layer casing slurry pump

The YMT slurry pump is an optimized design based on the theory of solid-liquid two-phase flow.

-

The ZP Series is a newly developed foam slurry pump with a unique impeller and blade design.

-

FGD flue gas desulfurization pump

Aiming at the characteristics of flue gas desulfurization project of thermal power plant

-

ZZ slurry pump is a research and development achievement for decades.

Company video

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

+86 28 8218 1182

-

+86 28 8218 1182