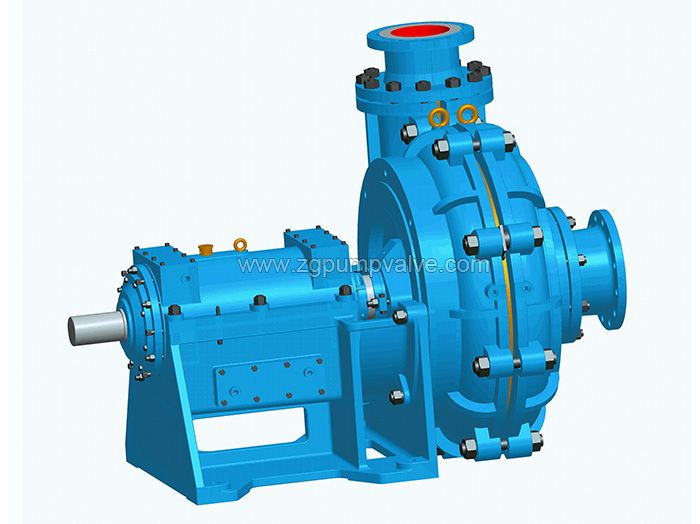

Slurry Pump

Fluorine plastic / UHMWPE lined wear-resistant slurry pump

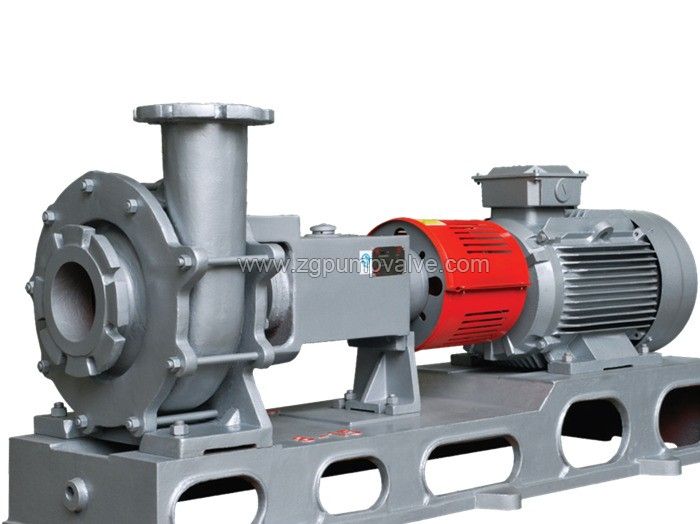

FDV series high temperature slurry pump is a single stage end suction cantilever centrifugal pump, which flow parts are lined with ultra-high molecular weight polyethylene (UHMWPE), and it has excellent performance of corrosion resistance, wear resistance, impact resistance. Fluorine plastic lined wear-resistant centrifugal pumps are used to handle with slurry containing solid particles and sewage containing various impurities, as well as acid and alkali medium. They are especially suitable for conveying hydrofluoric acid, fluorosilicic acid, phosphoric acid, hydrochloric acid, dilute sulfuric acid, concentrated alkali and other medium containing a great number of particles.

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

■ Flow rate: Q=3~140 (m³/h)

■ Total head: H=5.5~60 (m)

■ Speed: n=195-1450rpm

■ Pump diameter: 110~180 mm

■ Temperature: T=≤180℃

■ Pump efficiency: ≥56%

1. The flow parts are all lined acid-resistant and wear-resistant ultra-high molecular weight polyethylene (UHMWPE).

2. The metal frame of the acid-resistant wear-resistant slurry pump has strong bonding force with UHMWPE materials, which has impact resistance, steady operation and long service life.

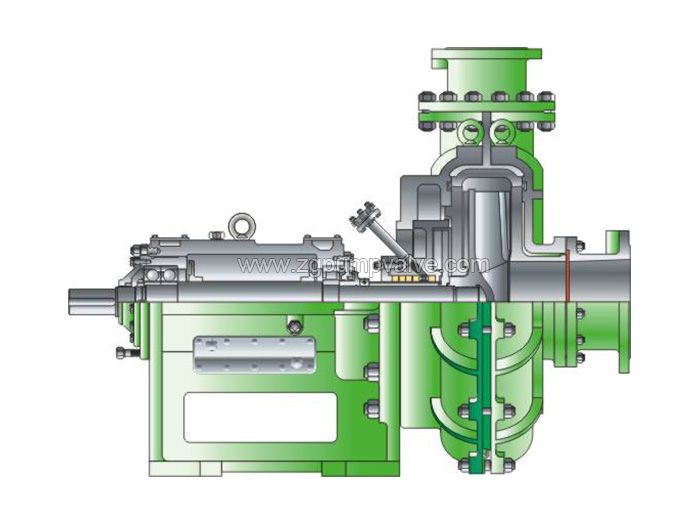

1.The pump body is composed of a metal skeleton and a lining of ultra-high molecular weight polyethylene, with a lining thickness of 8 ~ 20mm;

2. According to the amount of solid content, open, closed, semi-open impeller could be selected.

3. According to the working conditions, mechanical seal, packing could be selected.

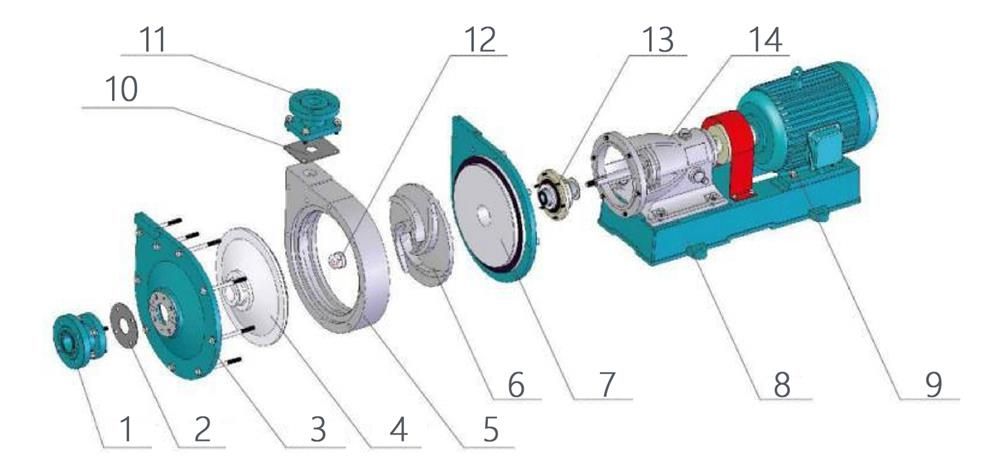

| 1. Inlet pipe | 2. Inlet pad | 3. Front splint |

| 4. Front pump cover | 5. Pump casing | 6. Impeller |

| 7. Rear pump cover and rear splint | 8. Base plate | 9. Motor |

| 10. Outlet pad | 11. Outlet pipe | 12. Impeller end assembly |

| 13. Sealing component | 14. Bearing housing |

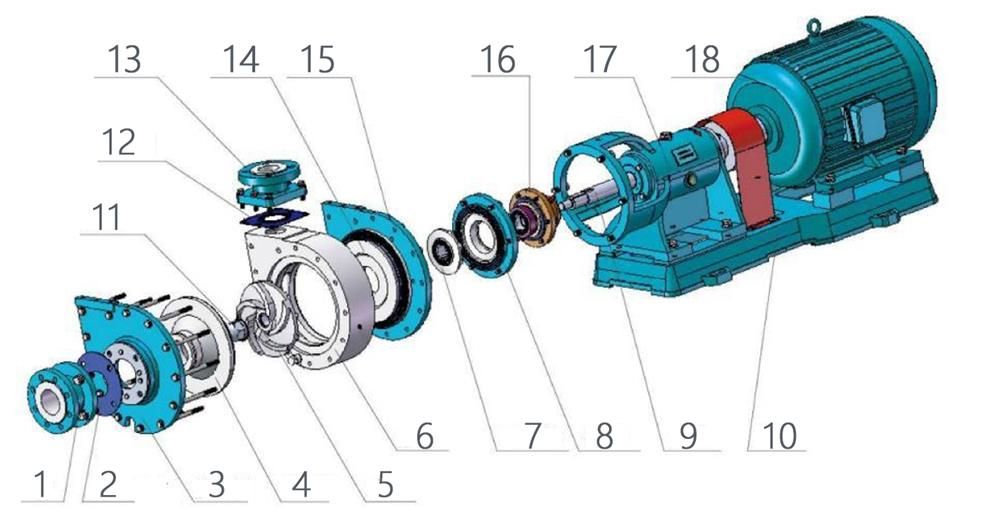

| 1. Inlet pipe | 2. Inlet pipe | 3. Front splint |

| 4. Front pump cover | 5. Impeller | 6. Pump body |

| 7. Auxiliary impeller | 8. Abutment ring | 9. Shaft |

| 10. Base plate | 11. Impeller end assembly | 12. Outlet pad |

| 13. Outlet pipe | 14. Rear pump cover | 15. Rear splint |

| 16. Sealing component | 17. Bearing housing | 18. Motor |

The liner of flow parts are all made from corrosion-resistant and wear-resistant ultra-high molecular weight polyethylene (UHMWPE) materials, which have characteristics of high hardness, strong flexibility strong wear resistance, acid resistance, and small thermal expansion coefficient.

Pump casing & cover: lining materials could be selected: UHMWPE (Ultra-high Molecular Weight Polyethylene), PFA (Perfluoroalkoxy resin), PVDF(Polyvinylidene Fluoride), PVDF (Fluorinated Ethylene-Propylene), etc.

Impeller material options: UHMWPE (Ultra-high Molecular Weight Polyethylene), PFA (Perfluoroalkoxy resin), PVDF(Polyvinylidene Fluoride), PVDF (Fluorinated Ethylene-Propylene), PP-R (Polypropylene Randon Coplymer) , etc.

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Mechanical seal |  | Zigong brand | Burgmann, Sihuan Riji, Chengdu Yitong |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

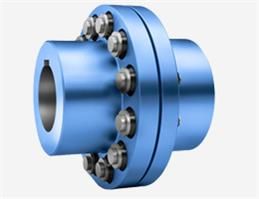

| Couplings |  | Pin type | Flexible diaphragm coupling |

Sulfuric acid phosphate fertilizer industry: transport of dilute acid, mother liquor, sewage, seawater, silica-containing fluorosilicic acid, phosphate slurry and other media.

Non-ferrous metal smelting industry: Especially suitable for lead, zinc, gold, silver, copper, manganese, drill, rare earth and other wet smelting of various acid, corrosive pulp, slurry (filter press) electrolyte, sewage and other media transportation.

Chemical and other enterprises: all kinds of sulfuric acid, hydrochloric acid, alkaline, oil clear liquid or slurry positions.

Chlor-alkali industry: hydrochloric acid, liquid alkali, electrolyte, etc.

Water treatment industry:pure water, high purity water, sewage (leather sewage, electroplating sewage, electronic sewage, paper sewage, textile sewage, food sewage, domestic sewage, pharmaceutical sewage, etc.).

Iron and steel enterprises: sulfuric acid, hydrochloric acid post of pickling system, sewage with impurities.

Supporting wet desulfurization dust collector: it can apply to alkaline, acidic and corrosive sections at the same time.

-

ZZ slurry pump is a research and development achievement for decades.

-

FGD flue gas desulfurization pump

Aiming at the characteristics of flue gas desulfurization project of thermal power plant

-

The ZP Series is a newly developed foam slurry pump with a unique impeller and blade design.

-

Single-layer casing slurry pump

The YMT slurry pump is an optimized design based on the theory of solid-liquid two-phase flow.

Company video

-

End Suction Pump Selection: An Ultimate Guide 2025-ZGPV Presents

-

What Is A Self-Priming Pump? An Ultimate Guide-ZGPV Presents

-

Solución de Problemas en Bombas Sumergibles: Guía Definitiva 2025

-

End Suction Pump vs. Inline Pump: What Are The Differences?

-

Vertical Seawater Pumps Run At Optimal Hydraulic Efficiency Steadily

-

End Suction Pump Selection: An Ultimate Guide 2025-ZGPV Presents

-

What Is A Self-Priming Pump? An Ultimate Guide-ZGPV Presents

-

Solución de Problemas en Bombas Sumergibles: Guía Definitiva 2025

-

End Suction Pump vs. Inline Pump: What Are The Differences?

-

Vertical Seawater Pumps Run At Optimal Hydraulic Efficiency Steadily

-

+86 28 8218 1182

-

+86 28 8218 1182