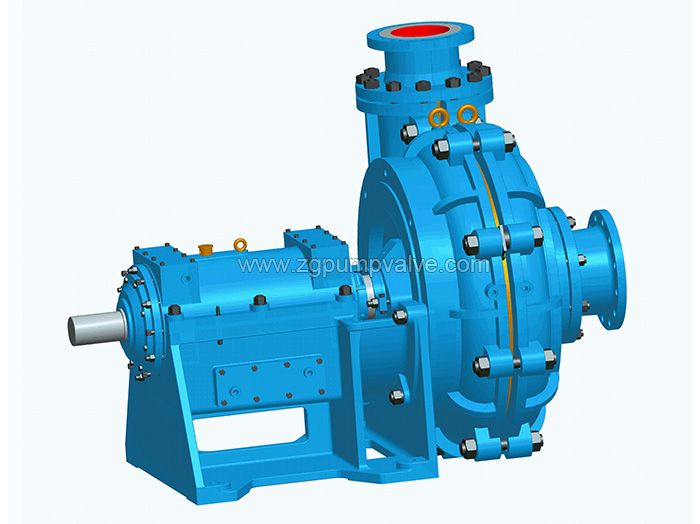

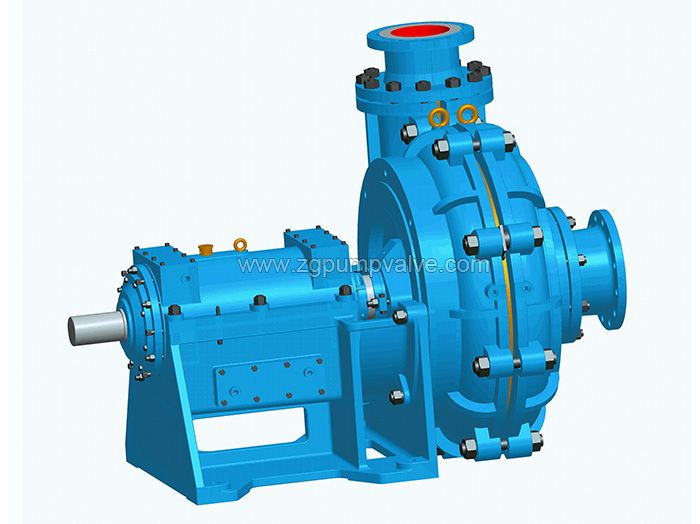

Slurry Pump

Foam slurry pump

The ZP Series is a newly developed foam slurry pump with a unique impeller and blade design. With an expanded pump inlet, the ZP Series foam mud pumps easily manage heavy foam and high viscosity slurries, as well as low NPSHr fluids. It is suitable for tough floating foam applications and heavy duty foam delivery. Ordinary ZZ slurry pump only needs to install an open impeller for foam slurry, a cavity guard and a new front shell can be replaced with ZP foam slurry pump.There are various materials available for our foam slurry pump, including cast iron, stainless steel SS304, SS316, SS316L, duplex stainless steel, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

■Flow rate: Q=10~5000(m³/h)

■Total head: H=20~120 (m)

■Speed: n=490~2900rpm

■S.g.: γ ≤1

■Temperature: T=0~120℃

■Pump diameter: 50~350mm

■Horizontal structure with a big loading capacity, easy for maintenance and is able to pump bigger foam flow rate.

■Unique design of open impeller with guide vane is appliable for the foam conveying of the most severe application.

■Heavy duty shaft with better performance in strength.

■Low pump speed and linear speed design to reduce the abrasion of pump.

■Optimized bearing configurations with full lubricating enables the long time operation.

■Various anti-abrasion materials for different applications.

■Axial split bracket and double layer casing structure.

direction at 45° interval.

■Horizontal installation of big loading capacity.

■The jacket and guard plate as the lining, pump casing and pump cover is the frame.

■Shaft sealings: dynamic seal, packing seal and mechanical seal.

■Transmission: Direct coupled, V-belt drive, variable frequency drive,hydraulic coupling.

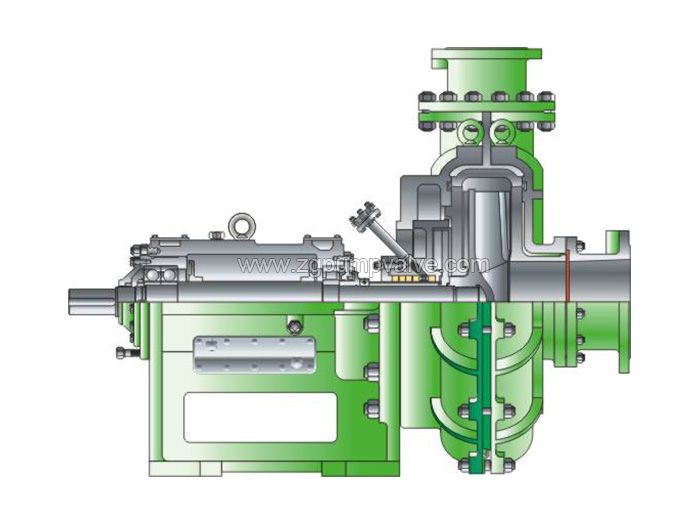

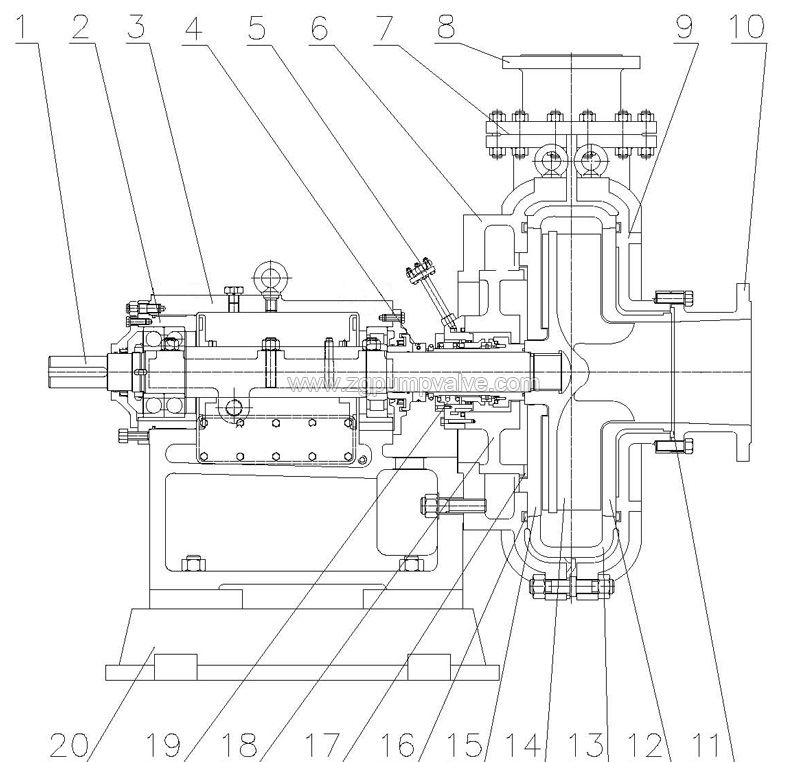

Structure drawing is as below

1. Pump shaft 2. Bearing box 3. Bracket component 4. Remove ring 5. Flushing pipe assembly 6. Rear pump body 7. Outlet seal ring | 8. Outlet nipple 9. Front pump body 10. Inlet nipple 11. Inlet seal ring 12. Front fender 13. Sheath 14. Impeller | 15. Rear fender 16. Groove seal ring 17. L shape seal sing 18. Seal chamber 19. Seal component 20. Pump base |

■Material of flow passage components based on pumped medium: Cr26 wear-resistant material, or Cr30, CD4MCu wear-resistant and anti-corrosion material, and other general wear-resistant material.

■Material of pump casing, pump cover, bracket etc. supporting parts: gray cast iron.

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Mechanical seal |  | Zigong brand | Burgmann, Sihuan Riji, Chengdu Yitong |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

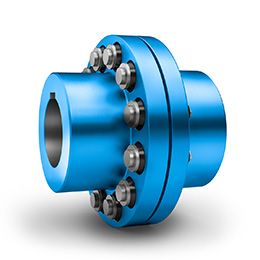

| Couplings |  | Pin type | Flexible diaphragm coupling |

■Severe applications of floating foams.

■Flotation producing process of ores.

■Slurries of heavy foam and high viscosity.

■Other similar applications.

-

FGD flue gas desulfurization pump

Aiming at the characteristics of flue gas desulfurization project of thermal power plant

-

ZZ slurry pump is a research and development achievement for decades.

-

The ZP Series is a newly developed foam slurry pump with a unique impeller and blade design.

-

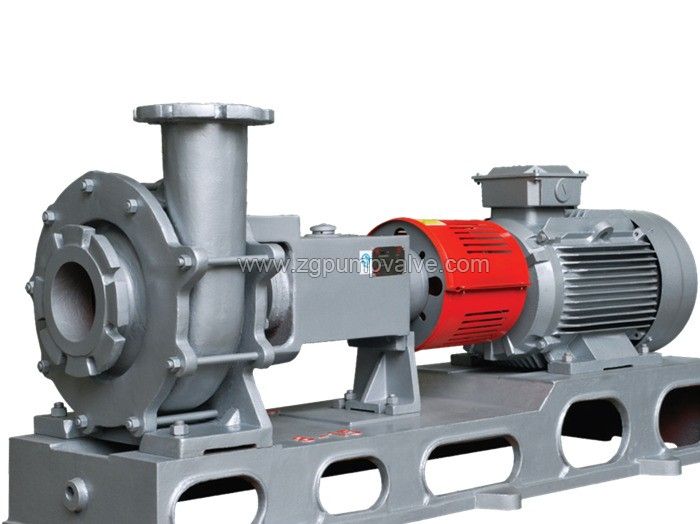

Single-layer casing slurry pump

The YMT slurry pump is an optimized design based on the theory of solid-liquid two-phase flow.

Company video

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

+86 28 8218 1182

-

+86 28 8218 1182