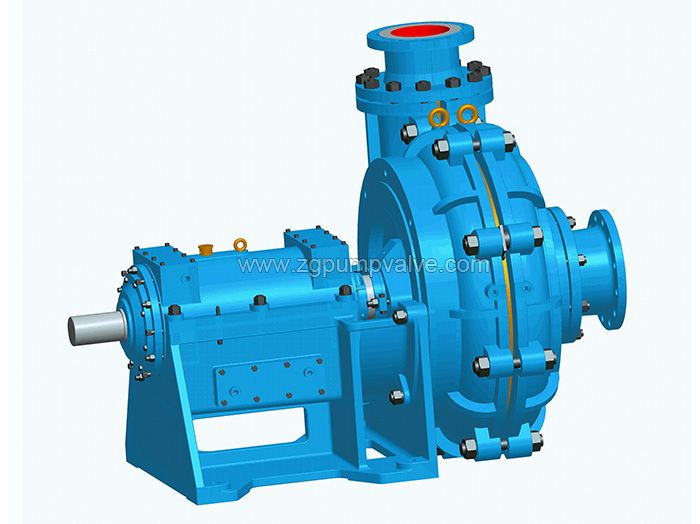

Slurry Pump

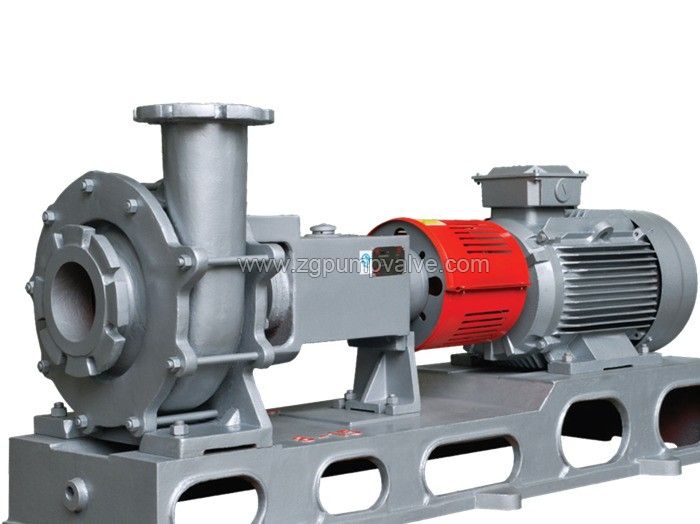

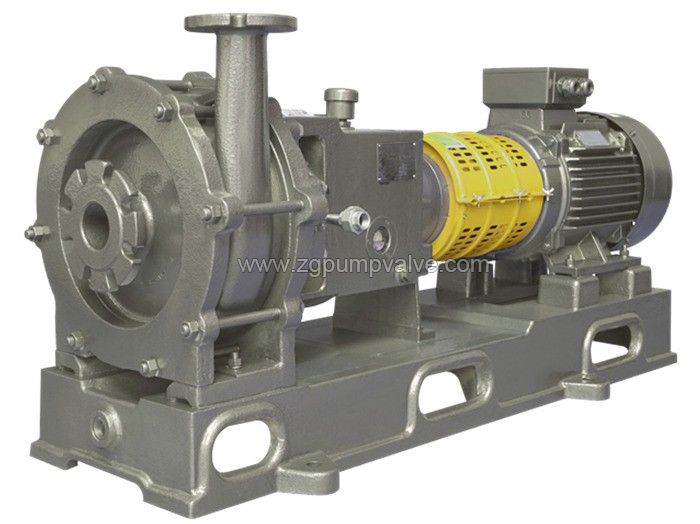

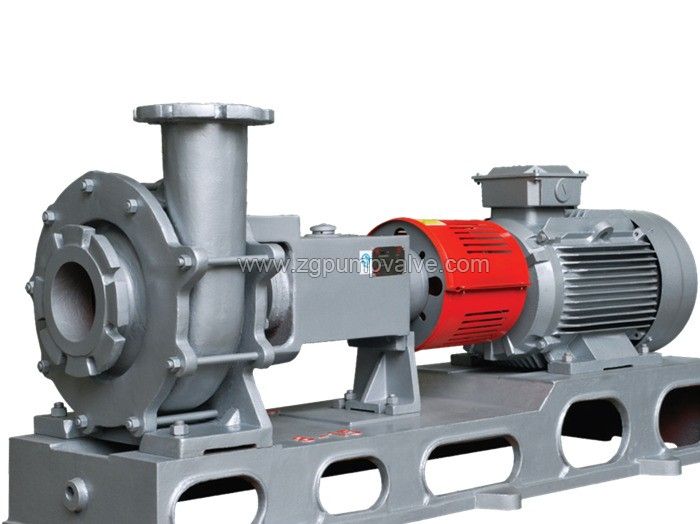

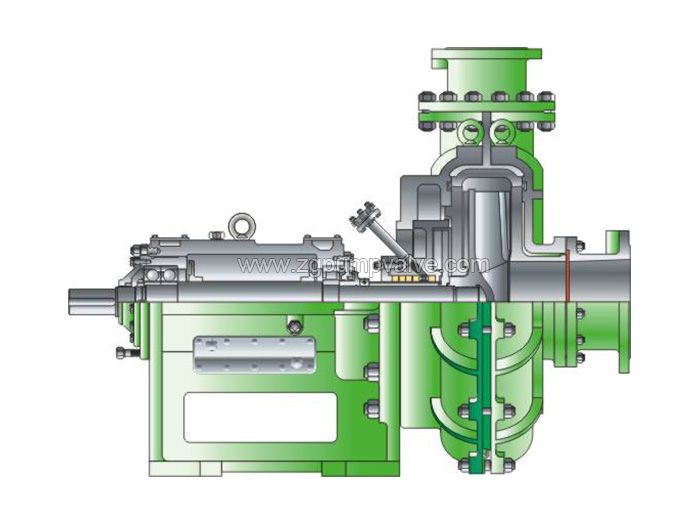

Single-layer casing slurry pump

The single layer light duty slurry pump is an optimized design based on the theory of solid-liquid two-phase flow. It is a low head slurry pump with a variety of seal types, drive types and anti-wear materials for different applications. Suitable for pumping corrosive or abrasive slurries containing solids such as concentrates, tailings, coal ash, cinders, slurries, sediments...There are various materials available for our single layer light duty slurry pump, including stainless steel SS304, SS316, SS316L, 904L, duplex stainless steel CD4MCu, 2205, 2507, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

■Flow rate: Q= 2~1000 (m³/h)

■Total head: H=8~100 (m)

■Speed: n=1450/2900rpm

■Temperature: T=-20~175℃

■S.g.: γ≤1.85

■ Rear door,no need to disassemble the suction and discharge pipeline during maintenance,convenient and easy installation.

■ Back vane design,reduce axial force,keep the solid in the medium from sealing cavity,improve the service life of mechanical seal.

■ Bidirectional balanced mounted conical cavity seal,no need to adjust the amount of compression,improve flushing,cooling,lubrication conditions,extend the service life of mechanical seal.

■ Special designed self-locking impeller nut,eliminate risk of release improve reliability.

■ Compound labyrinth bearing isolator,solve the problem of oil leakage,in the bearing box,and prevent dust,water etc. From entering,improve the service life and make the operation more reliable.

■Heavy duty shaft with better performance in strength.

■Various anti-abrasion materials for different applications.

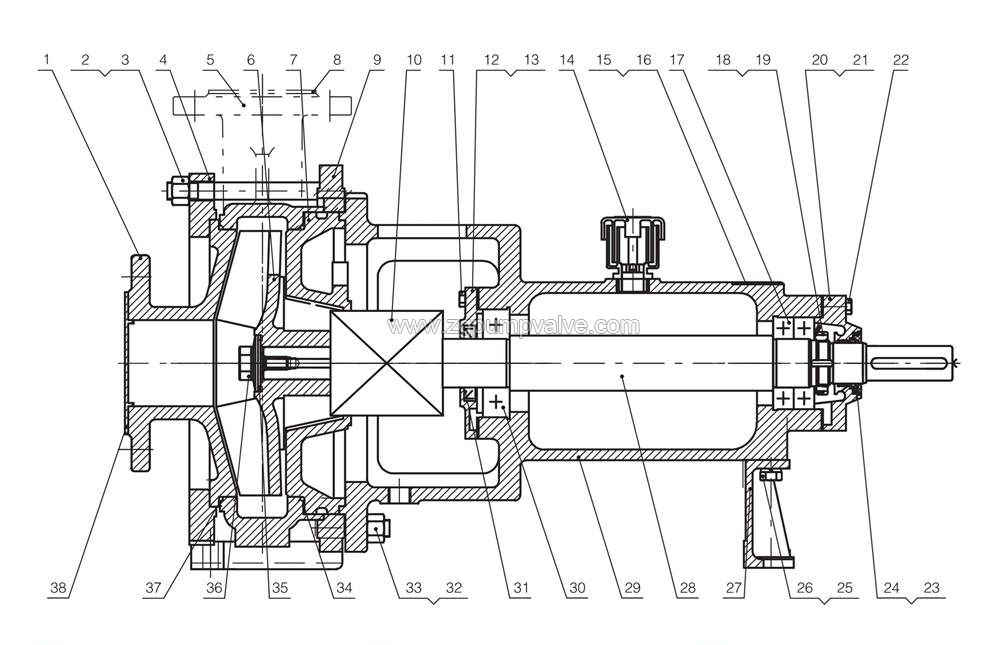

YMT series pump is a centrifugal pump of horizontal,single stage,single suction,cantilever design,its technical requirement conform to ISO5199.The pump is a centrifugal pump of horizontal,axial end suction and radial discharge design.The pump cover is fixed on the frame and is clamped tightly by pump casing and frame.

Structure drawing is as below:

1. Front cover 2. Double end stud 3. Nut 4. Pressure plate of front cover 5. Pump casing 6. Impeller 7. Pump cover 8. Seal 9. Pressure plate of pump cover 10. Mechanical seal 11. Bolt 12. Front bearing gland 13. Front cover pad | 14. Air vent cover 15. Warning sign 16. Rivet 17. Back bearing 18. Small round nut 19. Tab washer 20. Back cover pad 21. Back bearing gland 22. Bolt 23. O-ring 24. Ring for the sealing water 25. Spring washer 26. Bolt | 27. Bracket 28. Shaft 29. Frame 30. Front bearing 31. Skeleton oil seal 32. Nut 33. Double end stud 34. Gasket 35. O-ring 36. Impeller nut 37. Gasket 38. Seal |

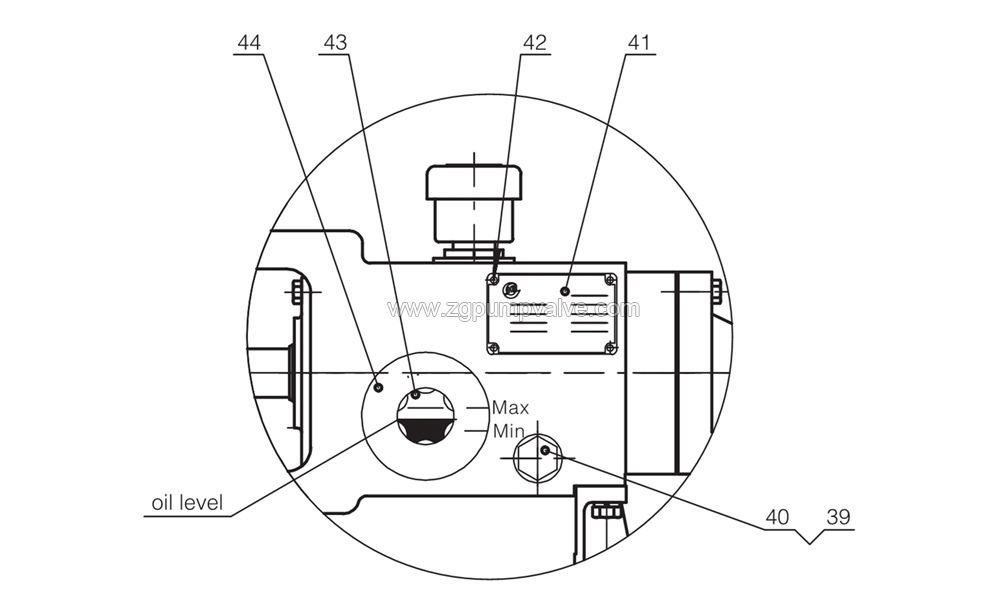

39. Pipe plug 40. Gasket | 41. Nameplate 42. Rivet | 43. Cross recessed counter sunk head screw 44. Circular oil |

Wetted parts comply to ASTM standard,common material as follow:

■ High-chromium alloy

■ Duplex stainless steel

■ Titanium alloy

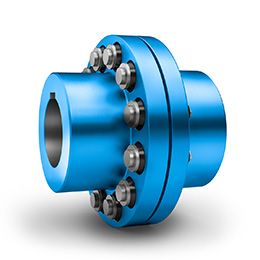

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Mechanical seal |  | Zigong brand | Burgmann, Sihuan Riji, Chengdu Yitong |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

| Couplings |  | Pin type | Flexible diaphragm coupling |

The YMT pump are designed for conveying slurry that contains less than 30% solids,conform ISO5099 standard,is the ideal equipment matched for abrasive molds,desulfurization in power plants,bauxite slurry and fluids contain hard sundries,to pump neutral or alkali slurries with solids.

-

The ZP Series is a newly developed foam slurry pump with a unique impeller and blade design.

-

Single-layer casing slurry pump

The YMT slurry pump is an optimized design based on the theory of solid-liquid two-phase flow.

-

FGD flue gas desulfurization pump

Aiming at the characteristics of flue gas desulfurization project of thermal power plant

-

ZZ slurry pump is a research and development achievement for decades.

Company video

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

+86 28 8218 1182

-

+86 28 8218 1182