■Gas range: 4.8----450m3/min

■Limit vacuum degree: 33hpa----160hpa

■Efficiency: 40----65%

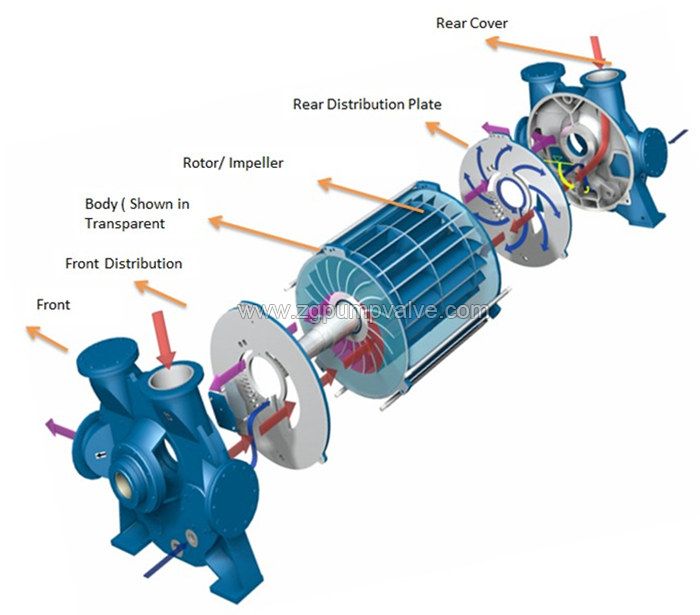

■ Single stage, single function, optimized design of distribution plate and impeller, high efficiency, simple structure and easy maintenance.

■ The flexible valve plate automatically adjusts the exhaust Angle, so that the pump can operate efficiently under different suction conditions.

■ The impeller end face adopts grading design, which reduces the sensitivity of the pump to dust and water scale formation in the medium.

■ Packing gland is divided into half structure, more convenient to replace packing.

■ Small size pump, with packing and mechanical seal two types of shaft seal.

■ Rotor with impeller diameter greater than 200mm, shaft sealing position is equipped with shaft sleeve to protect shaft wear.

■ Improved bearing structure, large axial and radial bearing capacity, accurate positioning, to ensure reliable operation of the pump.

■ Equipped with heat exchanger to realize working liquid circulation, reduce water consumption, no need to set additional booster.

■ When installed with cavitation prevention device, the cavitation resistance of pump running under higher vacuum can be improved effectively.

■ Adopt specially designed steam separator to separate, effectively reduce resistance and reduce noise.

■ The smooth surface of the flow component can effectively reduce the precipitation and reduce the scaling process.

■ Wide suction range, with a stage injector, suction pressure can be lower than 33hpa.

■ The only rotating part of 2BEA/2BEC ---- impeller makes the working fluid form hydraulic pressure in the oval pump body by rotating.At this time, the working fluid plays three roles of sealing medium, compression medium and cooling medium at the same time, without wear and lubrication.

■ In the exhaust stage, the liquid ring gradually approaches the hub, and the pumping medium is discharged from the exhaust port along the axial direction.

■ Continuous injection of supplementary liquid to compensate for the liquid taken away by the exhaust gas.

■ In the suction stage, the liquid ring is gradually away from the hub, and the pumping medium is sucked axially from the suction port.

■ Because the impeller is eccentric with respect to the rotating liquid ring, the liquid reciprocates in the space between the blades, ------ just like the movement of the piston in the cylinder, ------ produces axial suction and compression on the pumping medium.

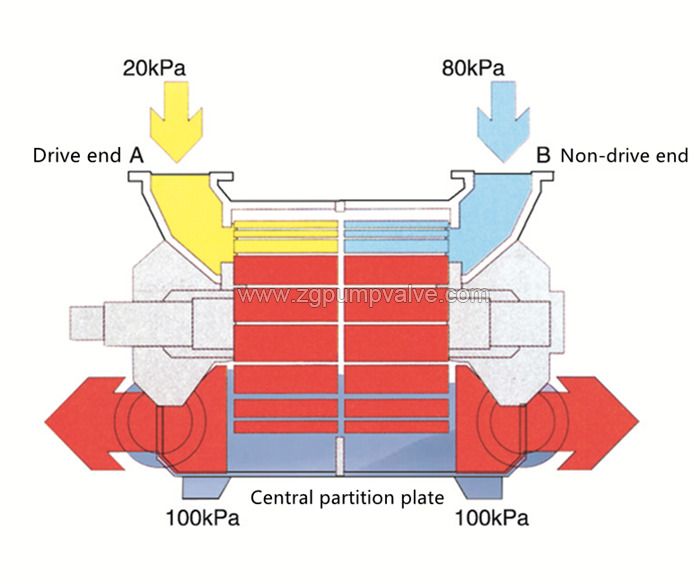

It operates at two vacuum levels

When fitted with an intermediate separator, the left and right parts of the 2BEC pump body can operate at different vacuum levels.As long as the suction pressure difference between the two parts (A to B) is less than 80 kPa, A 2BEC can be used as two independent vacuum pumps.This feature further enhances the operational flexibility of 2BEC.This flexible solution minimizes energy consumption and footprint in applications that require both vacuum levels.Because the 2BEC was designed with the possibility of long term operation under large differential pressures in mind, its reliability under these operating conditions is not diminished at all.

■2BEC series water ring vacuum pumps are widely used in petrochemical, pharmaceutical, food, sugar industry and other fields. Because the gas compression process is isothermal during the working process, it is not easy to compress and pump flammable and explosive gases. It is dangerous and its application is more extensive.