Water Pump

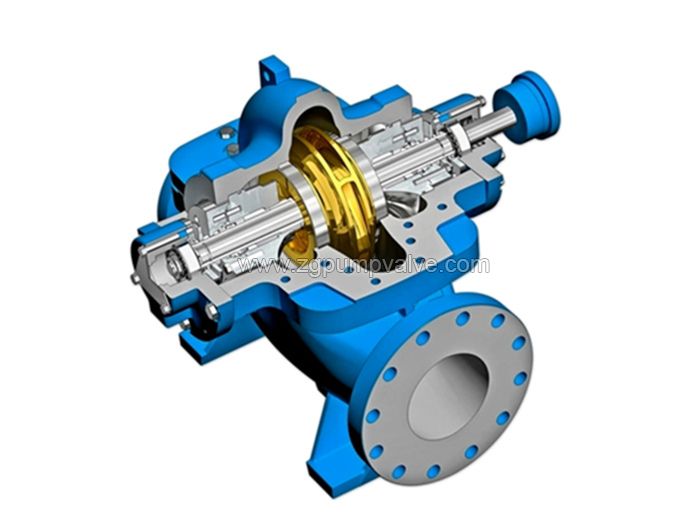

Split volute casing double suction pump

COS series split volute casing double suction pump is a new generation of high performance single-stage double suction centrifugal split pump.They are mainly used in delivering liquids of the water plant,air conditioner circulation water,heating pipe network system,building water supply,irrigation and drainage of pump stations,power plants,industrial water supply system,fire protection,ships industry and mine.There are various materials available for our double suction pump, including stainless steel SS304, SS316, SS316L, 904L, duplex stainless steel CD4MCu, 2205, 2507, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

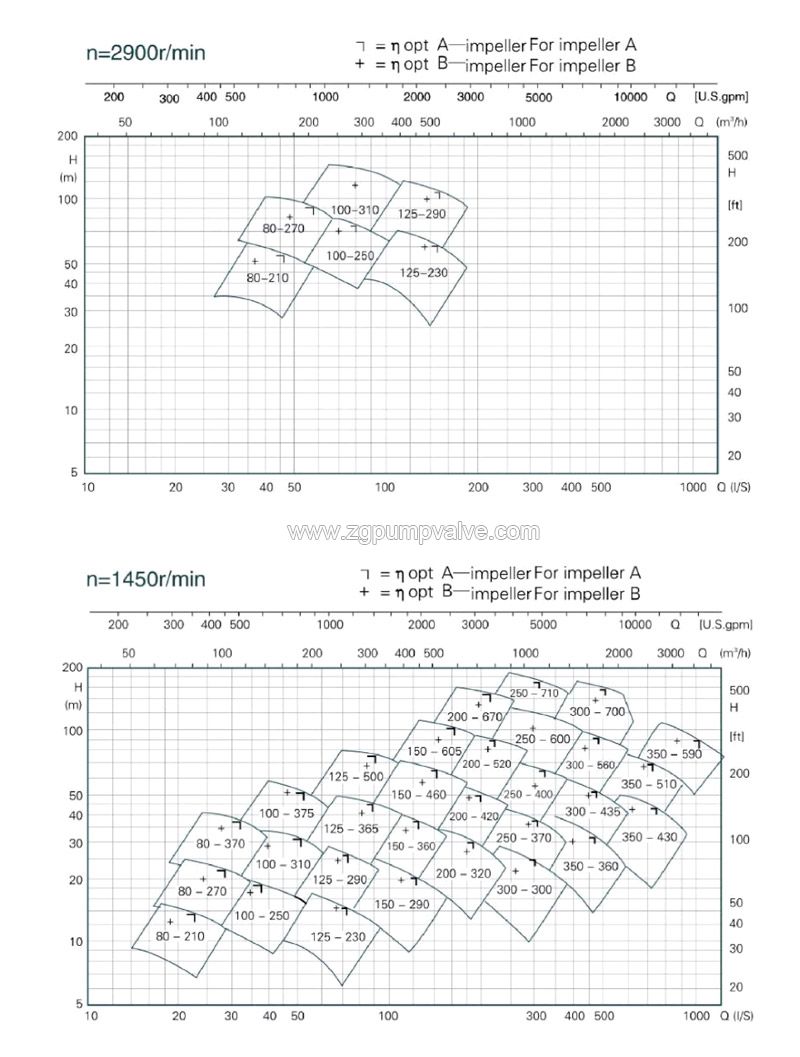

■Flow rate: Q=22~16236m3/h

■Total head: H=7~300m

■Speed: n=980rpm/2950rpm

■Solid parameter: ≤80 mg/L

■Temperature: T=-20~200℃

■Using excellent hydraulic model, the efficiency of the pump is 2-3% higher than that of the same type, and the operating cost of the pump is reduced.

■Unique high temperature design, the pump adopts intermediate support, thickened pump body, sealed cooling, bearing thin oil lubrication, so that the pump can be applied to the high 200ºC operating conditions, especially suitable for heating pipe network requirements.

■The pump body part can be installed vertically or horizontally according to different working conditions, and the seal can be mechanical seal or packing seal.

■The NPSHr is reduced by 1-3 m.

■It is unnecessary to adjust mechanical seals,so it is very easy and simple to replace them.

■It is rapid and simple to assemble and dismount the rotor parts due to using elastic prestress assembling.

■The distance between the two ends of the pump is short, the pump runs stably, the vibration noise is small, and the speed can be increased properly, so that the pump can adapt to a wider range.

■The inlet and outlet are in the same straight line, so that the pipeline layout is simple, convenient and beautiful.

■The same rotor can run in reverse, reducing the risk of water hammer damage to the pump.

■It is unnecessary to make adjustment to any clearance when assembling.

Structure drawing is as below:

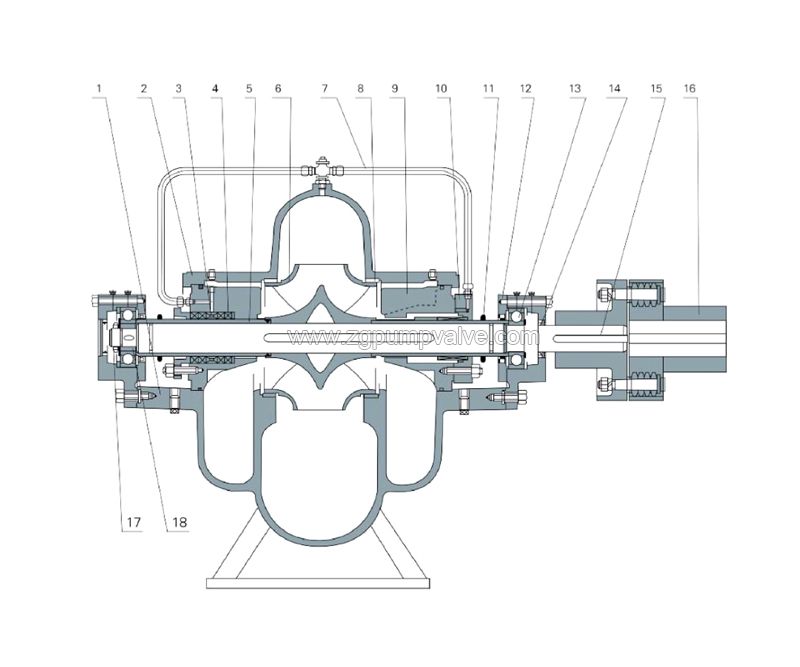

1. Construction section of type COS pump

1. Pump casing 2. Impeller 3. Pump cover 4. Flushing water piping 5. Seal ring 6. Pipe plug | 7. O ring 8. Seal housing 9. Packing gland 10. Block water ring 11. Bearing gland 12. Bearing housing | 13. Shaft 14. Skeleton oil seal 15. Circlip 16. Bearing block ring 17. Bearing 18. Shaft sleeve |

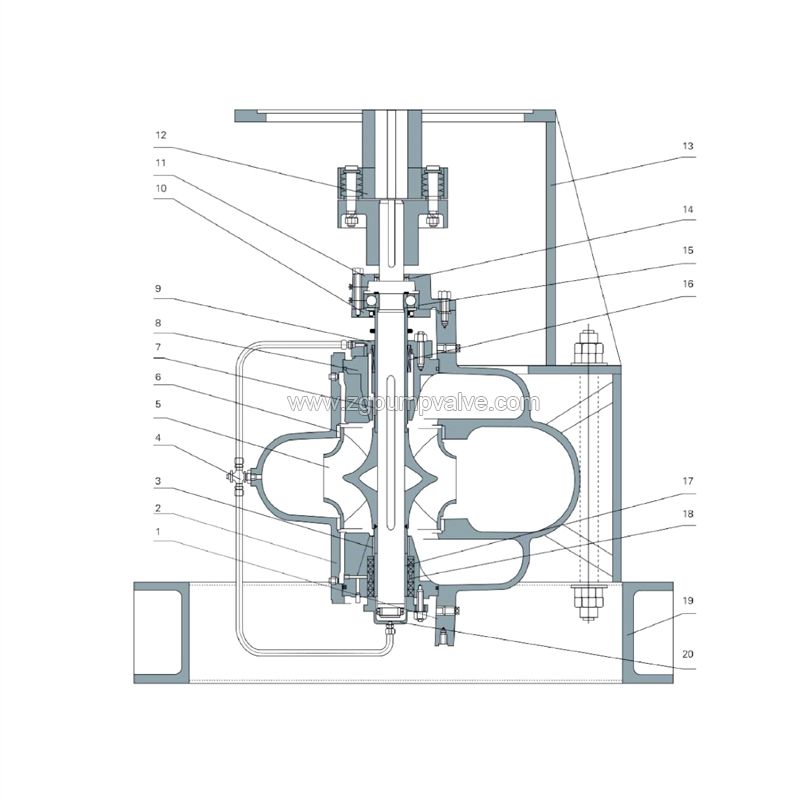

2. Construction section of type COS (L) pump

1. Pump casing 2. Pump cover 3. Sleeve 4. Shaft 5. Impeller 6. Seal ring 7. Shaft sleeve | 8. Vent plug 9. Seal housing 10. Flushing water piping 11. Packing gland 12. Bearing cover 13. Bearing housing 14. Bearing block | 15. Bearing block ring 16. Circlip 17. Skeleton oil seal 18. Bearing 19. Motor stool 20. Mechanical seal or packing |

| No. | Description | Material | |||||

| Anti-corrosion alloy | Cast steel | Stainless steel | |||||

China standard | ASTM standard | China standard | ASTM standard | China standard | ASTM standard | ||

| 1 | Pump casing | 20# Alloy Titanium Nickel 904L Ti/Pd Alloy Monel | Hastelloy Monel Ⅱ-B Ⅱ-C Ni-Resist1 Ni-Resist2 Ni-Resist3 | 25# 35# | WCA WCB | ZG1Cr13 ZG2Cr13 ZG00Cr18Ni10 ZG0Cr18Ni9 ZG0Cr18Ni12Mo2Ti ZG0Cr17Ni4CuNb ZG1Cr18Ni9 ZG1Cr18Ni9Ti ZG00Cr17Ni14Mo2 0Cr26Ni5Mo2 0Cr17Mn13Mo2N 00Cr18Ni5Mo3Si2 | CA-15 CA-15M CF-3(SS304L) CF-8(SS304) CF-8M(SS316) CF-3M(SS316L) CN-7M(SS320) CD-4MCu 2205 |

| 2 | Sealing ring | ||||||

| 3 | Impeller | ||||||

| 4 | Pump cover | ||||||

| 5 | Impeller nut | ||||||

| 6 | Cartridge seal | ||||||

| 7 | Shaft | Carbon steel SS420 2205 SS304 SS316 | |||||

| 8 | Bearing Housing | Cast iron | |||||

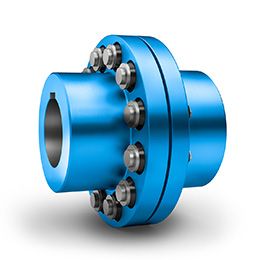

| Item | Factory standard | Optional configurations | |

| Motor |   | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |   | Reputed China brand | SKF, NSF, FAG or designated brands |

| Flanges&counter flanges |   | China standard | European std, German std, American std, Japanese std |

| Couplings |   | Pin type | Flexible diaphragm coupling |

■ It is suitable to pump clean water and fluids have close physical and chemical characters of water.

■Widely used in sections of mining,city water supply,power plant water supply and drainage,farm irrigation and various water conservancy project.

Company video

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

+86 28 8218 1182

-

+86 28 8218 1182