Water Pump

ZX series self-priming pump

ZX series chemical self-priming pump is based on the relevant technical information from domestic and overseas by adsorption, digestion, improved from development of energy-saving pump. It has several characters which include a compact structure, easy operation, smooth operation, easy maintenance, high efficiency, long life, and have strong self-absorption capacity and so on.No need to install the pipe end of the valve, before work just to ensure that there is quantitative pump priming can be.So it simplifield the piping system, and improved the working conditions.There are various materials available for chemical self-priming pump, including stainless steel SS304, SS316, SS316L, 904L, duplex stainless steel CD4MCu, 2205, 2507, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

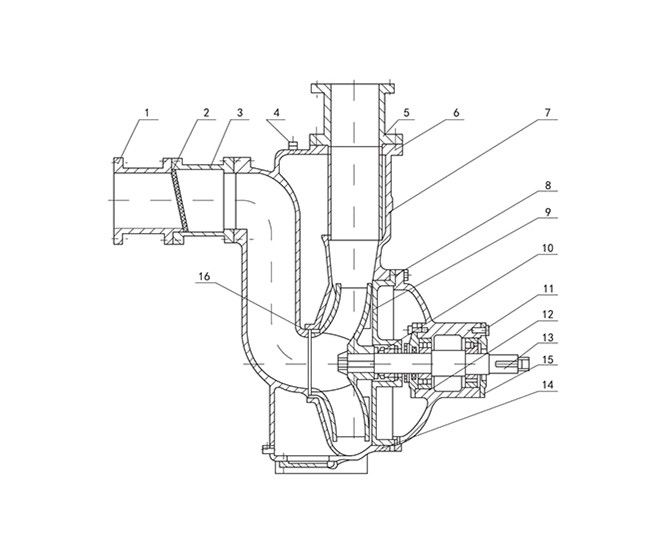

Structure

-

MOC

-

Configuration

-

Application

-

Performance

■Flow rate: Q= 8~800(m³/h)

■Total head: H=12~60 (m)

■Self-priming depth: 4.5~6 (m)

■Pump speed: n=1450/2900rpm

■Design temperature: T=-20~90℃

■Fluid s.g.: γ≤1.3

■Solids Handling Impeller

Two-vane, semi-open, solids handling impeller handles up to 3" (76 mm) diameter solids, depending on pump model. Pump out vanes on impeller shroud reduce foreign material buildup behind impeller and reduce pressure on seal and bearings for extended pump life.

■Exclusive Abrasion-Resistant Seal

Exclusive double-floating, self-aligning oil lubricated mechanical cartridge seal with stationary and rotating face of silicon carbide is specifically designed for abrasive industrial waste water service.

■Removable Cover Plate

Removable cover plate provides quick and easy access to pump interior without disconnecting piping. Clogs can be removed and pump returned to service in minutes. Impeller, seal, wear plate and flap valve can also be accessed through cover plate opening for inspection or service.

■Replaceable Wear plate

ZW Series pumps feature replaceable wear plates which fasten to the cover plate and can easily be removed for inspection or service. No expensive castings to replace.

■Removable Rotating Assembly

Removal of rotating assembly allows easy inspection of pump shaft or bearings without disturbing pump casing or piping. On most models, simply remove four bolts from the back of the pump and the rotating assembly slides out.

■Drive Variations

ZW Series Pumps are available as basic units for connection to customers' power source or may be flex-coupled or V-belt driven by an electric motor. Pumps may also be powered by gasoline or diesel engines. Electric motor driven pumps with "standby" engine power are also available.

1. Inlet nipple 2. Inlet flange 3. Inlet valve seat 4. Water filling bolt 5. Outlet nipple 6. Pump casing | 7. Air-liquid separating pipe 8. Rear cover 9. Impeller 10. Mechanical baffle 11. Water baffle 12. Bearing seat | 13. Pump shaft 14. Bearing cover 15. Bottom cover-plate 16. O ring |

| No. | Descripition | Material | ||||

| CI | Cast steel | Stainless steel | ||||

China standard | ASTM standard | China standard | ASTM standard | |||

| 1 | Pump casing | CS | WCA WCB WCC | ZG1Cr13 ZG2Cr13 ZG00Cr18Ni10 ZG0Cr18Ni9 ZG0Cr18Ni12Mo2Ti ZG0Cr17Ni4CuNb ZG1Cr18Ni9 ZG1Cr18Ni9Ti ZG00Cr17Ni14Mo2 0Cr26Ni5Mo2 0Cr17Mn13Mo2N 00Cr18Ni5Mo3Si2 | CA-15 CA-15M CF-3(SS304L) CF-8(SS304) CF-8M(SS316) CF-3M(SS316L) CN-7M(SS320) CD-4MCu 2205 | |

| 2 | Sealing ring | |||||

| 3 | Impeller | |||||

| 4 | Pump cover | |||||

| 5 | Shaft | Carbon steel, SS420, 2205, SS304, SS316 | ||||

| 6 | Shaft sleeve | SS304, SS316, SS316L, CD4MCu, 2205 | ||||

| 7 | Sealing cover | SS304, SS316, SS316L, CD4MCu, 2205 | ||||

| 8 | Bearing housing | Cast iron | ||||

| 9 | O-rings | Oil-resistent rubber | ||||

| Item | Factory standard | Optional configurations | |

| Motor |  | ReputedChina brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | ReputedChina brand | SKF, NSF, FAG or designated brands |

| Mechanical seal |  | Zigong brand | Burgmann, Sihuan riji, Chengdu Yitong |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

| Couplings |  | Pin type | Flexible diaphragm coupling |

1. Municipal engineering, waste water treatment, constructional engineering

2. Sewage collection or discharge in residential community

3. Sewage discharge in hospital and hotel

4. Centralized and staged disposal in sewage treatment plant

5. Water drainage station

6. Seriously polluted water discharge

7. Agricultural irrigation etc.

Company video

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

Duplex Stainless Steel Centrifugal Pumps VS Titanium Centrifugal Pumps: The Best Choice

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part Two)

-

What Is A Self Balancing Wear Resistant Multistage Pump ? (Part One)

-

Reciprocating Triplex Plunger Pumps For Reverse Osmosis Seawater Desalination: A Comprehensive Guide

-

+86 28 8218 1182

-

+86 28 8218 1182